Typical lighting panels (ОShch) belong to the category of equipment designed exclusively for servicing the supply circuits of 380 Volt lighting systems. Unlike power cabinets, the load value in them is strictly regulated and does not exceed the established norm. In addition, they provide the ability to change the operating mode of individual groups of illuminators through the use of built-in switching devices.

OSH classification

Modern electrical lighting boards are classified according to a number of characteristics, the main of which are the body material and the installation method. All OSh models are divided into products made of the following materials:

- metal;

- non-combustible plastic.

Metal housings are used in panel structures, which are supposed to be used outdoors. Therefore, they are reliably protected from external influences and bad weather and have a high IP rating.

To extend the service life, typical outdoor panels are additionally treated with special impregnations and coatings. The high degree of security allows them to be installed at facilities with increased operational hazard. Their non-combustible plastic counterparts have an attractive appearance and are suitable for indoor use.

A distinctive feature of shields of this type is their fire safety, since the plastic used in the manufacture does not burn.

Depending on the installation method, the lighting control panel can have the following versions:

- in the form of a hinged structure;

- product embedded in the wall.

Wall-mounted, closed cabinets are ideal for installation in factories and other production sites. They are hung in a place convenient for placement and fixed to the walls by means of mounting dowels.

Built-in boards installed in corridors and on staircases must be equipped with locks, the keys to which are kept by the electrician on duty. Most of them are attractively designed and installed in places where aesthetics are emphasized. If the general environment is disturbed, it is recommended to install them in niches available in most service rooms.

Design and equipment

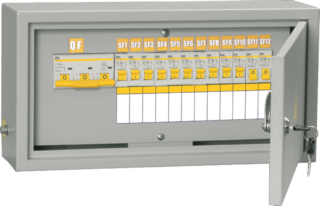

Requirements for the design and electrical circuit of the lighting board are practically the same as for its distribution counterpart. The mains power is supplied through a breaker designed for the total load of the served lighting lines. The cable entry to the light control unit is protected by a separate circuit breaker. Purely structurally, a modern lighting shield is a switchgear with fastening elements placed in it.

To fix the mounted devices, guides called DIN rails are used.

The following switching equipment is located inside the cabinet:

- automation devices;

- linear automatic machines for the protection of outgoing lines;

- opening switch.

In addition, it may contain control and monitoring equipment. Protection of lighting circuits against current leakage by means of an RCD, as a rule, is not applied. Here, in the cabinet, there are special blocks for connecting grounding conductors.

Specifications

It is more convenient to consider the technical parameters of light control panels using the example of the ОShch series, manufactured in accordance with TU3434-006-33874352-2004. The characteristics of products in this category include the following features:

- protection of single-phase group networks from overloads and short-circuit currents, for which they provide single-pole circuit breakers;

- the presence of internal lighting;

- admissibility of connection to the input cable in several ways (by means of a packet switch or using special power terminals);

- cable entry through top or bottom openings with removable covers;

- the number of input conductors connected to one terminal usually does not exceed 2 pieces;

- the maximum section of these tires is 50 m2;

- shields ОЩ, ОЩВ and УОЩВ are designed for operating voltages of 380/220 Volts and have a mass from 13 to 24 kg.

Products of the OSH and OSHV categories are equipped with switches of the AE2050, A3161 or A63 series and are hung on the walls. UOSCHV shields of the same configuration are intended for installation in niches. All considered products have a degree of protection IP20 corresponding to GOST 14254-96.

Shields for portable illuminators

According to PUE 7 (latest edition), for portable lamps used in high-risk rooms, it is allowed to use a supply voltage of no more than 50 Volts. To obtain it, potential-lowering transformers are used that convert the mains 220 Volts into 12, 24, 36 or 48 Volts.

For service of portable illuminators, prefabricated panels of a special design are produced, which include the following units:

- voltage transformer;

- automatic machine used for input protection;

- automatic machines protecting lines outgoing to the consumer;

- socket for connecting portable lamps.

In some models of cabinets, cable lines are diverted from the secondary winding of the transformer through the automatic machine to stationary luminaires, which are constantly located in one place.

According to the PUE, dangerous conditions in which the use of portable lamps is mandatory include work performed in confined spaces:

- in trenches (when laying cable lines, for example);

- in observation pits and basements;

- inside tanks and bulk tanks;

- when the contractor is in an uncomfortable position;

- if there is a possibility of contact with the elements of grounding devices.

In all these situations, the permissible voltage should not exceed 12 Volts.

The step-down transformer can be installed in the switchboard itself, for which a special box from the YATP series is provided in it.

Outdoor lighting shield

Special control panels for outdoor lighting differ from conventional products by the organization of the network connection, which can be done manually or in automatic mode. The following electronic components are used for automatic switching of loads:

- motion sensors recording movement in the illuminated space;

- a photo relay that responds to the level of illumination in the controlled area;

- sound sensors;

- time relays that turn on the load at the right time.

In some models of cabinets, a radio communication channel is used to control the operation of the illuminators in automatic mode. With its help, it is possible to remotely turn on and off the light on the controlled object.

Manual activation

This lighting control mode applies in the following cases:

- when carrying out routine maintenance or emergency repairs;

- in case of failure of automation systems;

- if necessary, setting up and testing new equipment.

To transfer the system to manual mode, use the special switches installed on the flap door or on its side panel. This switching can be done in one of the following ways:

- by moving the manual control key to the desired position;

- by means of a special switch installed on the outside or inside the cabinet;

- using a push-button station (this option is most often used in the factory).

To transfer the panel to group lighting control in automatic mode, you will need to switch back.

Emergency lighting

Emergency lighting shields are self-contained systems with cable circuits connected to them, laid directly from the input device. They are connected through a reserve input system, which assumes the presence of two independent power supplies.

In contrast to the operating mode, the emergency lighting cannot be switched off manually as there is no separate switch in the corresponding equipment. This type of control system has only two modes: the emergency lighting is always on or off automatically by means of magnetic starters and their control automatics.

Placing shields

Special requirements are imposed on the order of placement of lighting boards associated with the peculiarities of their installation.

- Cabinets are installed in areas at least one meter away from sewerage, gas and water supply lines.

- The panel room must be reliably protected from flooding. If it is impossible to ensure such conditions, they should be placed above the expected water level.

- Boards intended for outdoor lighting are mounted at a height of at least 20 cm from the floor or concrete base.

- If snow drifts are possible, such structures are installed on a special elevation (foundation).

If there is measuring and control equipment in the cabinet, it must be heated. Exceptions are panel structures equipped with devices operating at temperatures below 5 degrees.