If the wiring is faulty, a crackle appears in the light switch when turned on. Occasionally, the phenomenon is accompanied by sparks. It will be easy for people who know how to work with electrical equipment to find and fix the malfunction.

- The main causes of the problem

- Oxidation of contacts

- Weakening of the plate

- Inconsistency of lamp power to contacts

- Poor performance of contacts and plates

- Other causes of faulty contacts

- Switch failure symptoms

- Varieties of switches

- Required tools

- Repair algorithm

- Features of disassembling the device and cleaning the contacts

- How to repair touch switches

- How to prevent sparking

- Spark arresting chains

- Pressure plates

- Removing carbon deposits

The main causes of the problem

The crackling sound may resemble a hum or buzz. There are several reasons for a breakdown.

Oxidation of contacts

If the contacts of the device are overgrown with carbon deposits or oxidized, an electric arc occurs at the moment of their approach. The cause of sparking is complicated by the size of the carbon deposits. When offshoots form on the end plates, the wiring can catch on fire, that is, the contacts will close.

Weakening of the plate

The spring, which squeezes the contact at the moment of switching on, weakens - the characteristic sharp and clear click is no longer heard. The malfunction is indicated by a soft switch on of the device and the need to press the button for the light to appear. The danger is that the switch sparks continuously, causing fire risks.

Inconsistency of lamp power to contacts

A halogen lamp or high power LED source places a load on the contacts. The easiest way to resolve the issue is to replace the switch with one that matches the lighting power rating.

Poor performance of contacts and plates

Breakdown typical for budget models. The button works on the principle of soft start, which in combination with low-power automatic machines provokes sparking.

Serious malfunction is accompanied by sparks, heating and crackling at the same time.

Other causes of faulty contacts

Other factors that trigger sparks and crackles in the switch include:

- high humidity - activates the oxidation reaction;

- incorrect or loose connection of the cores;

- increased load on contacts - buzzing occurs;

- constant voltage fluctuations.

Broken contacts will lead to failure of household appliances.

Switch failure symptoms

To understand that the switch is broken, the following signs will help:

- the device may not turn on at all;

- there is a crackling sound at the moment the key is pressed;

- at the moment of switching on, the light bulb burns out;

- when turned on, the lighting device will flash and crackle;

- the case heats up if the switch is operated for a long time;

- the key is jammed - it must be pressed several times;

- the lighting does not turn on.

Most problems arise from improper wiring or from the switch itself.

Varieties of switches

When the switch cracks or sparks when turned on, it is necessary to install a new device or repair it. Flickering of light, switching on with a bang can lead to line closures, fires, breakdowns of household appliances. To properly repair the device, you need to understand its design.

Manufacturers produce the following product modifications:

- With one, two, three keys. Designed for indoor installation. To turn on the device, you need to press the key, closing the circuit.

- Push-button. Models that have an LED indicator. By design, they do not differ from standard ones.

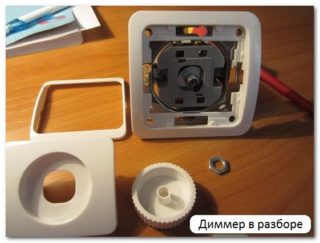

- Dimmer. Allows you to adjust the lighting at the discretion of the user - adjustable brightness or intensity. The contacts are activated by turning the wheel.

- Repeated. Devices that turn on the light by turning a button on the case.

Depending on the type of control, you can choose sensor devices, devices with a timer, acoustic or remote versions.

Most houses and apartments have key switches that are easy to fix.

Required tools

When a spark appears in the switch, it is not necessary to call a professional electrician. Uncomplicated breakdowns can be removed by yourself.

For work you will need:

- indicator screwdriver - a model with a light bulb or an electronic display is suitable;

- a standard screwdriver, with which screws and screws are unscrewed;

- insulating tape;

- fine-grained sandpaper;

- pliers;

- marker;

- office knife for removing the insulation from the cable.

Before starting the repair, you need to know the design of the device. Switches are produced in a plastic case, have internal operating units and a frame. It is attached to the device with screws or latches. The main mechanism is located in a socket, fixed with spacers or screws.

For ease of access to the contacts, you will need to remove the outer part from the switch.

Repair algorithm

If the switch is short, you can fix it yourself, working in stages:

- De-energizing the line. The machine turns off in the input panel.

- Checking the presence of voltage. This can be done by touching the indicator screwdriver to an outlet in another room.

- Dismantling the device. You will need to remove the switch from the groove, remove the decorative strip. After that, the voltage is checked again, the screws on the sides are unscrewed, the case is taken out of the socket.

- Disconnecting cables. For two-key models, you will need to mark the lead wire with a marker.

- Disassembly of the case and search for contacts. The contact block is located above the plastic button set on the screws.

- Elimination of breakage. The contacts are cleaned or the device is completely replaced.

- Reassemble the case in reverse order, reconnect the wires. The finished mechanism in the case is returned to the socket.

- Turning on the machine in the dashboard and testing the switch for serviceability.

The old switch is not worth repairing - the light will flash again. Better change your device.

Features of disassembling the device and cleaning the contacts

- Removing the adjustment knob. You will need to remove semicircular parts or splines. Hold the body with one hand, and gently pull the handle with the other.

- Removing the retaining lock nut or screws. Work with a screwdriver, turning it counterclockwise.

- Removing the plastic trim and frame.

- Looseness of the internal fastening of the dimmer mechanism.

- Removing the switch from the socket.

Contacts are in the form of hemispheres. If carbon deposits are found, the elements should be cleaned to a shine with sandpaper. If carbon deposits are not completely removed, the contacts are cleaned with a screwdriver sting.

Before fully assembling the case, it is best to see if the wires are tightly tightened.

How to repair touch switches

Sensor modifications are equipped with a remote control and special boards with control chips. It is worth disassembling such a switch after reading the manufacturer's instructions.

Repair of the device:

- Removing the decorative trim.

- Visual search for the panel with sensors, which is located under the plate. Depending on the number of lines served, there are 1-3 elements.

- Search for the sensitive area on the overlay - sensors are indicated by circles.

- Detection of LEDs on the position of the switch (red - on, blue - off). Under this panel are the nodes to which the conductors are connected.

- Disconnecting inputs and outputs. It is required to remove the clips securing the touch panel.

- Removing the bolts from the case fixed to the socket, inspecting problem areas.

- Checking the voltage on individual cables. The defective wire is replaced.

- Reassembling the mechanism. The main unit is connected to the power supply, placed in a socket box and fixed with screws. After that, the touch panel and decorative strip are attached.

Feature of the touch switch is power interruption in case of breakdowns. If the light bulb burns out, the device is turned off. It does not change even after installing a new lamp. To turn on the light, you need to touch the plate.

How to prevent sparking

To prevent sparks from forming on the contacts, manufacturers install arc extinguishing chambers that cool the arc. Some brands may solder from materials that are not subject to oxidation. The current will pass through them. You can use several methods on your own.

Spark arresting chains

Suitable for high-speed devices that generate sparks at the moment of short circuit. Most often, they put two options:

- For DC mains relays and starters. You will need a diode with an anode to the negative pole and a cathode to the positive. Energy dissipation (self-induction) occurs on the active part. The diode will close the circuit.

- Snabber. The RC shunt circuit is designed to dissipate the energy accumulated in the inductance at the moment of the active resistance of the network.

The contacts are close together, so the spark suppression circuit reduces the load.

Pressure plates

The method is suitable when the contacts of the starter or machine are arcing. A special spring mechanism ensures that the contact pads are in tight contact. To connect, you will need to install the spring mechanism in the closed contact position, pulling it back and lowering it back. A click-bump should be heard.

Work is carried out in a voltage-free network.

Removing carbon deposits

You can clean the surface of the conductors not only with fine sandpaper. An eraser, a wooden match will provide a smooth surface, eliminate the risk of an increase in transition resistance.