Manufacturers of LED floodlights claim that the devices can work for many years without needing to be repaired. In reality, breakdowns happen quite often. If the blinking effect of the LED spotlight is detected when it is on, the cause may be a faulty power supply or wiring. In addition, defective parts or unaccounted for external influences are often the source of malfunction.

- Operating principle

- Reasons for the flashing of the spotlight

- Spotlight blinking due to motion sensor

- The reason for blinking is weather conditions

- The spotlight blinks when turned on or during operation

- Advanced functionality

- Device malfunctions and how to fix them

- Wiring violations

- Backlight elements and irregularities in the power circuit

- Diode bridge and smoothing capacitor

- LED mounting errors and current-limiting capacitor

- Burnout matrix

- Feasibility of self-repair

Operating principle

The easiest way to understand why an LED floodlight blinks is to imagine it as a powerful light source. In the inner space of its body there is an emitting lamp, the beam from which, passing through the system of reflectors, is directed to the desired area. Due to this, the concentrated light beam acquires a special saturation and brightness.

The principle of operation of an LED is based on the emission of light quanta in a junction, where electrons accelerated by voltage knock out free photons.

To obtain an overclocking potential, these emitters are equipped with a rectifier and a driver that stabilizes the current value and, if necessary, regulates its value. In addition, the device can include an independent power supply unit that allows you to obtain a rectified voltage of 12 Volts.

Reasons for the flashing of the spotlight

When buying cheap Chinese floodlights, a characteristic malfunction is often found, which manifests itself in continuous flashing. The sources and signs of this unpleasant phenomenon can be:

- incorrect setting of the motion sensor;

- unsuitable weather conditions;

- malfunctions in the power supply system;

- incorrectly selected mode.

Another likely cause is a malfunction in the switch backlight.

Spotlight blinking due to motion sensor

If the spotlight starts blinking immediately after connecting the motion sensor, it is most likely a malfunction of the latter. This can happen for the following reasons:

- violation of the settings of the sensitive device;

- loss of contacts;

- undervoltage;

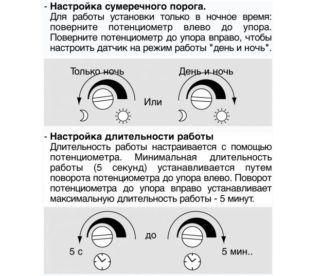

The spotlight may start flickering due to an incorrectly set timer, which ensures the system is operational for a specified period of time. In this case, it is recommended to reconfigure it and then check the device again. The so-called "floating" contact manifests itself as a lack of signal transmission to the illuminator itself. If you suspect this malfunction, you should check all the connections and tighten the fastening screws in the existing blocks and terminals.

Reduced mains voltage also often manifests itself as the blinking of a searchlight, which does not have enough power to fully ignite. Another reason for the phenomenon under consideration may be a factory defect that was not noticed during the acceptance of the product. In this case, you should return it to the workshop for warranty or current repair.

The reason for blinking is weather conditions

In frosty winter weather, the LED floodlight, brought out into the cold, also often refuses to work, starts blinking. Some well-known models of diode illuminators flicker already at -10 degrees.

With strong cooling, the starting circuits begin to work intermittently, which leads to an undesirable effect. In this case, the question is solved in the simplest way - the searchlight is brought into a warm room and allowed to settle, and by nightfall it is put back in place.

The spotlight blinks when turned on or during operation

If the illuminator starts blinking only when turned on, the reason is most likely a malfunction of the starting capacitor, which is replaced with a new product. If this does not help, you should check the quality of the contact in the switch itself or in the voltage supply wire.

The second situation is possible if a backlit product is used to control the switching. If it is present, the searchlight simply does not have enough current, which is partially branched off to the duty chain. The way out is to turn off the backlight, which does not allow the projector to start and work normally.

Advanced functionality

Some models of floodlights have additional options to expand their capabilities. One of them is the use of strobe mode, which is sometimes activated by itself. To eliminate this effect, completely disconnect the device from the mains, and then turn it on again. After that, most often, its performance is restored.

Another reason for the manifestation of this malfunction is the peculiarities of controlling additional features, when several functions are activated at once with one button. In this case, you must first turn off the spotlight, and after turning it on, double-click on the strobe activation button and follow the disappearance of the problem.

Device malfunctions and how to fix them

It is possible to start repairing the device only after the exact cause of the malfunction has been established and the location of the malfunction has been localized. This is not so easy to do, since there are many explanations for this.

Wiring violations

Sometimes the cause of the flickering effect is a banal mistake when switching wires supplied to the projector. The problem in this case is solved simply - just swap them. Blinking with a low and unequal frequency is possible if the contacts in the cable connector are broken.

This is due to the large currents flowing through the working veins of the searchlight, which, when the contact is broken, begin to increase and warm it up. The location of this malfunction can be both in the junction box and in the motion sensor, as well as in the power supply connectors or in the switch.

Backlight elements and irregularities in the power circuit

If there is a backlit switch or an IR sensor in front of the illuminator lamp, situations are possible when pulsations appear with a frequency of about 25 vibrations per second. This is due to the peculiarities of the passage of half-waves of current in the supply circuit, which in this case "work" through one. This problem is eliminated by simply turning off the backlight LED.

Another option is to replace the motion sensor with another type (ultrasonic or inductive device).

Failure of the elements of the electric power supply of the searchlight is also frequent. They are found mainly in cheap Chinese lighting designs. To eliminate these problems, the device is taken to the workshop.

Diode bridge and smoothing capacitor

In the circuits of Chinese floodlights, rectifiers of 220 Volt half-wave type are used.They differ from the double bridge circuit in the quality of the rectified current, which is characterized by a high level of ripple. The smoothing capacitor behind it does not completely eliminate them, which leads to flickering. The way out is to purchase high-quality floodlights with a "classic" 2-bridge rectification circuit.

Damage to the electrolytic capacitor also increases the supply voltage ripple. In this case, the installation of a transformer will help, reducing the voltage amplitude to 12 volts. Accordingly, the level of ripple will also decrease, after which the lamp will start to light up and work normally.

LED mounting errors and current-limiting capacitor

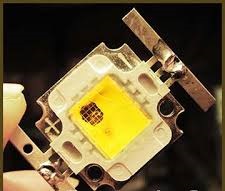

With a low assembly quality of the LED matrix, its contacts are often not soldered very reliably, which is also a possible cause of blinking. In this situation, there is only one way out - to hand over the matrix of the searchlight for repair. A current-limiting capacitor can also lead to undesirable effects if its rating and operating voltage are incorrect.

Manufacturers, saving on LEDs, are trying to increase the brightness of the glow by connecting a capacitor with a low operating voltage to the driver. Replace this part with a 400 volt product and the flicker should disappear.

Burnout matrix

This case is a serious violation, since the main element - the LED matrix - fails. If a malfunction is detected, its body is taken out of the searchlight, for which, first, 4 screws are unscrewed and the capacitors are soldered off. Then a new diode assembly is bought, and the following operations are performed:

- A little thermal paste is applied to the heat dissipating surface.

- The current-carrying contacts are soldered.

- The new die is secured with 4 screws.

In its shape, it should not differ from the burned-out emitter and therefore it can be easily mounted on the seat.

Feasibility of self-repair

Despite the comparative complexity of the LED floodlight device, if you wish and have some skills, you can fix it yourself. In this case, the cost of new component parts, if required, and the complexity of the upcoming operations are necessarily taken into account. If the malfunction is very simple - the contact disappears or the capacitor is incorrectly selected, - you can do the restoration at home.

In case of more serious violations, you will have to contact a workshop, where experienced specialists will quickly eliminate the malfunction that has arisen. In this case, you will have to spend money on repairs. However, this is the case about which they say that the miser pays twice.

In general, it is a disgrace that for these purposes people everywhere do not use three-phase bridge circuits of full-wave mains voltage rectifiers, which, relative to the working neutral wire of the network, can perfectly work as bipolar mains rectifiers, giving between the output of the positive pole of the cathode group of three diodes of a three-phase bridge full-wave mains rectifier with respect to the working neutral wire of the network, the rectified voltage is + 300 V, and between the negative terminal of the anode group of three diodes of a three-phase bridge full-wave network rectifier and the working neutral wire of the network giving a rectified voltage of 300 V, and a full constant rectified network voltage of 600 V between positive and negative the leads of the cathode and anode groups of diodes of a three-phase bridge full-wave network rectifier with two identical electrolytic capacitors installed, one of which is switched on in compliance with the polarity of n and the positive output of its cathode group of its three diodes and a working neutral wire of the network,and the other of which, observing the polarity opposite to it, is connected to the negative terminal of its anode group from its three other diodes and the same working neutral wire of the network. And the three-phase network in this case will be energetically advantageous symmetrically in phases and economically loaded with lighting load, and not only on one of its phases relative to the working neutral wire !!! Alexei.