Performing electrical work must be carried out in compliance with fire safety standards. As one of the protective means when installing a two-, three-core cable, a metal corrugated pipe is often used. It performs a fire-fighting function and protects the cable from mechanical stress.

Corrugated wire for electrical wiring

Corrugated metal pipe is a special protective conduit for wiring, hollow inside. Most often, tubes are made of galvanized steel, which ensures their moisture-proof properties.

Corrugated pipes are used in the following cases:

- Laying an electrical cable behind or on top of flammable panels: frame, wooden panels, lining, polymer finishing materials.

- Laying a metal corrugated hose for electrical wiring in a cement floor screed or other concrete structures. In addition to mechanical protection of the cable from squeezing, the pipe allows you to change, if necessary, old wires for new ones without dismantling the monolithic filling.

- Open-ended electrical wiring from the street side: powerful cables for lighting, complex equipment, etc.

- Installation of underground power supply systems.

- The wiring device is close to gas pipelines, heating communications.

- Parallel cable routing to avoid cable crossing.

According to the PUE (clause 2.1.64), the metal corrugation for wiring must be completely sealed.

Types of corrugated metal pipes

On the market you can find the following types of tubes:

- Stainless steel. They have the highest cost among the options presented.

- Galvanized. They contain a special fabric that ensures the integrity of the connection of the corrugation links.

- Steel with polymer (PVC) braiding. Designed for cable installation in places of increased explosion hazard, in soil, water. This type of pipe is characterized by increased tightness.

- Tinplate. The lightest kind of metal corrugation. Relevant when installing electrical wiring in places with high humidity. The tightness of the link joints is ensured by a special polypropylene film.

Protective ducts are always cut in one piece according to the length of the cable to be laid. Joining of two tube cuts is not allowed.

How metal corrugated board works

The corrugated metal hose works on the principle of a containment barrier with high pressure on the wired hose. This is especially true for the installation of a cable in the soil. Tuba links act as stiffeners here.

If we take for comparison smooth-walled and corrugated pipes with the same nominal diameter, the area of the second will be much larger than the first. Here you can track the principle of the protective channel using the formula from the school course in general physics:

- P = F / S,

where the values are interpreted as follows:

- P is the pressure on the pipe;

- F is the force that acts on the surface perpendicular to its plane;

- S is the area of the required surface.

After analyzing the formula, it becomes clear: the greater the total surface area that is subjected to mechanical stress (pressure from outside), the less it is for each cm2 of the sleeve.

Technical characteristics of corrugated metal hoses

All metal corrugations for electrical wiring have a number of their own technical parameters and characteristics. They should be taken into account when choosing channels. Most often, information is presented in the form of markings on pipes. Metal corrugated tubes have the following parameters:

- Withstand load - up to 125 N / cm2, up to 320 N / cm2, up to 750 N / cm2, up to 1250 N / cm2, up to 400 N / cm2: very light, light, medium, high, very high load, respectively.

- Impact strength - from 0.5 kg / 100 mm to 6.8 kg / 100 mm.

- Rigidity - hard, flexible, extra flexible, memory-effect tube. In this case, the bending radius can vary within the range of 25≤R≤150mm.

- Temperature modes of operation - from -45 to +400 degrees Celsius.

- Roughness coefficient - 0.008.

- Thermal conductivity - 17 W / m * K.

- Internal section - 16-50 mm.

Corrugated metal sleeves have been in service for over 30 years.

How to choose a metal corrugation

The protective channel for laying the cable is selected according to various criteria, according to the conditions for performing electrical work.

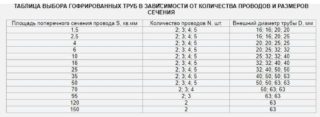

The first selection condition is the inner section of the sleeve. Here they rely on the electrical section that is being mounted:

- eyeliner to lighting points - 16 mm;

- to switches or sockets - 20 mm;

- installation of a low-current cable (antenna, telephone, internet) - 25 mm;

- from the panel to the junction box - 25 mm;

- connection of two shields to each other - 32 mm;

- cable transition between floors - 40 mm;

- laying wires in the ground, collector pipes - 50 mm.

According to the level of flexibility, a corrugated pipe is selected taking into account the maximum possible pressure on the mounted channel:

- The light pipe has a low level of strength. Designed for installation of wiring under suspended or suspended ceilings, behind plasterboard structures, behind clapboard. Such thin-walled corrugated metal pipes for electrical wiring have the lowest cost.

- Medium strength heavy tuba. It is allowed to be laid in a cement screed, plaster, soil.

- Extra heavy sleeve. Indicated for use in premises with high fire safety requirements: public institutions with high attendance, hospitals, schools, kindergartens.

Experts recommend paying attention to the channel manufacturer. The most popular are:

- IEK (Russia);

- Legrand (France);

- Frankische (Germany).

It is advisable to ask the seller for a quality certificate for the selected product when buying.

Advantages and disadvantages

All corrugated metal pipes for wiring have a number of advantages:

- high service life (30-50 years);

- protection of the laid cable from small pests, rodents, mechanical damage;

- easy installation of the channel on the wires;

- the ability to replace old wiring with a new one without complicated dismantling work;

- subject to grounding, reliable protection against electric shock;

- resistance to moisture, pressure, temperature extremes;

- zero flammability level;

- relatively low weight.

The disadvantages of using a protective corrugated channel include:

- high costs for the wiring device;

- labor intensity of the process;

- the risk of condensation accumulation in the channel and, as a consequence, a decrease in the resistance of the wires.

Metal corrugations are sold in coils or in meters.

Materials and brands

For the production of protective channels, stainless or galvanized steel is often used. The first option is more durable (MRN brand). Stainless steel pipes are characterized by increased rigidity and tightness.

Another brand of products is MGPng. Such a corrugated steel pipe is produced using a special method of winding links, using a sealing thread and thickened insulation. The robust tube is characterized by increased flexibility.

MRPING brand - products with upper polymeric sheathing.

If you need reliable protection of the cable from water, oil products, it is better to give preference to the latter option.

Laying of electrical wiring in a metal corrugation

To freely pass the required length of the cable along the corrugated sleeve, you need to prepare:

- a piece of metal pipe equal to the length of the cable;

- a piece of electrical wire;

- a cap from a ballpoint pen or felt-tip pen;

- a piece of sanding paper.

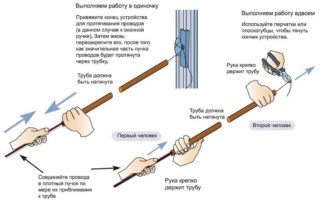

The work is done like this:

- With the help of a sandpaper, the protruding edges of the cap are removed so that it takes on a smooth cylindrical shape.

- The element is put on the end of the cable. They launch it into the corrugation and gradually push it until the cap appears on the other side of the channel.

- It is advisable to carry out the entire operation on the weight of the iron pipe in order to facilitate the passage of the wire through the channel.

This method is suitable for using a tube in which the old cable has already been laid. In the new channel, the device of wires is performed as follows:

- One end of the conductor (special wire in the pipe cavity) is slightly released.

- They pierce a two- or three-core cable 1 cm from its beginning so as not to damage the cores. Pass the end of the wire through the wire and twist it into a loop. The remnants of the conductor can be insulated so that they do not cling to the stiffeners in the protective sleeve when passing the power cord.

- The second (opposite) end of the cable wire must be tied to the "anchor" (heat sink, strong metal rail).

- It remains to pull the metal corrugated wire on the wire with both hands until its opposite end appears on the other side of the tube.

The assembled sleeve with the cable is attached to the wall of the house in special clips-clamps. They are placed in increments of 30-40 cm.