To design taps from high-voltage transmission lines, special switching devices are traditionally used. Their common name is a vacuum circuit breaker, which is explained by the peculiarities of the arc extinguishing chamber. It is possible to get acquainted with these devices in detail only after studying the prehistory of their appearance.

Historical reference

For the first time, vacuum circuit breakers were mentioned in the early 30s of the XX century, when devices were used to disconnect relatively low-current circuits operating under voltages up to 40 kV. To obtain reliable vacuum absorbers capable of switching off significant currents in circuits at high potential, a whole series of studies was required. When they were carried out, approximately by 1957, the processes observed during high-voltage arc burning were fully studied and systematized. It took another two long decades to move from prototypes produced in single copies to mass production of modern devices.

Operating principle

The principle of arc quenching is based on the fact of high electrical strength and special insulating properties of the artificially obtained vacuum, known from physics. When the power contactors are opened in the chamber where they are placed, an electric arc is formed, supported by metal particles evaporating from their surface. The absence of conditions for its stabilization prevents the development of the process peak due to the high dielectric properties of the vacuum medium.

Due to the significant dielectric strength of the vacuum, the moment of extinction of the arc shifts to a point preceding the maximum of its development. In electrical engineering, this phenomenon is called "current cut". Its presence negatively affects electrical networks, since switching overvoltages are a consequence of this process.

Features of application and operation

The majority of modern energy facilities have abandoned outdated designs and finally switched to new switches that are rather compact and do not need maintenance. This is due to the following reasons:

- the vacuum device is unpretentious and does not need regular cleaning of contacts or renewal of the medium;

- during the operation of the oil device, the filler constantly leaks;

- according to the data of the passport, the service life of vacuum devices reaches 20 years, which is much higher than the same indicator for other types of circuit breakers.

During operation, the drive mechanism often fails at the most inappropriate moment for this. To maintain it in working order, a special unit for manual spring charging is provided in the device. Mandatory for these devices is the presence of an emergency button, which allows disabling the mechanism for blocking the rolling out of the switchgear modules when the cabinet is on.This point concerns the safety of personnel operating equipment and requires close attention.

Design features

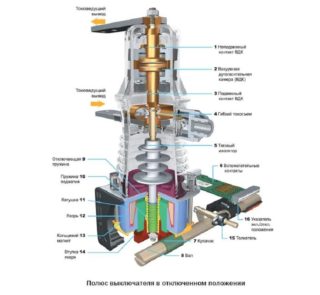

Each model of the high-voltage vacuum switch has individual characteristics, since it is intended for operation in networks with different electrical characteristics. In addition, manufacturers also make some adjustments to the design of their products. However, in general, the composition of the components of these devices remains unchanged. Main elements:

- A housing made on the basis of durable metal, inside which an on and off drive is mounted (it can be spring-loaded or of another type).

- 3-pole current collector designed for connection to a 380 Volt network and disconnected when the switchgear is transferred from the operating mode to the withdrawn position.

- A trolley for placement inside the case, which differs from other similar structures in its execution.

The electrical part of the product has special partitions that separate the phase sections from one another. It also has a complex structure and contains a number of elements described in the passport.

Varieties of vacuum switches

Products are usually classified according to the class of the potential they switch.

Among all the variety, the following types stand out:

- Devices for working with voltages of 6-10 kV.

- Devices for switching higher levels - up to 35 kV.

- Devices designed for extra-high voltage 110-220 kV.

Another “working” criterion for classifying circuit breakers is the power that they can transfer to the load. According to this parameter, their division is carried out in the same way as the classification of the consumer himself.

Advantages and disadvantages

The advantages of devices include:

- small dimensions;

- the ability to quickly replace individual sections;

- noiselessness and independence from orientation in space;

- safety for the health of service personnel.

They do not need replenishment of the protective environment and are highly reliable. But even these products were not without problems inherent in many electrical devices. The disadvantages of vacuum circuit breakers include:

- limited working currents;

- "Tendency" to overvoltage;

- small switching resource.

Despite the existing shortcomings, these devices have firmly taken their place in the list of the most modern switching equipment for explosives.

Features of selection and installation

The following important points are taken into account in the selection process:

- the protective characteristics of the device must correspond to the parameters of the network in which it is supposed to be operated;

- the switch is selected based on the most severe operating conditions;

- rated current and voltage must exceed the corresponding parameters for the protected network;

- breaking current must not exceed the value guaranteed by the manufacturer.

Before installing the vacuum circuit breaker, you must carefully examine the place of its installation and make sure that there are no damages or defects. Then you will need to clean the insulated pole surfaces with a dry cloth.

It is not allowed to install new equipment in a system, on the insulating surfaces of which there are chips, cracks and severely deformed areas.

The secondary circuit diagram with the subsequent connection of the "ground" bus is subject to mandatory check. The vacuum circuit breaker itself is attached directly to the moving part of the trolley using special bolted hardware.

The most common models

Among the most common models of vacuum chambers, the following stand out:

- VVE-M-10–20.

- VVE-M-10-40.

- VVTE-M-10–20.

Almost all product samples from this list are a further development of old oil circuit breakers and are capable of operating in AC and DC circuits. Installation, subsequent adjustment and commissioning of high-voltage vacuum devices are time-consuming procedures that determine their further functionality. Therefore, the listed operations are entrusted only to specialists with the appropriate qualifications.

When installing the device, the sequence of setup operations must be followed. Compliance with this requirement is the basis for the safety of operating personnel or an electrician on duty authorized to work with high-voltage equipment.

Products belonging to the category of vacuum circuit breakers need professional selection and evaluation, since their operation is associated with high voltages.