A concrete blind area is a structure that plays an important role in protecting the foundation, basement and walls of the house from dampness. A monolithic blind area is a strip towering above the ground, passing along the perimeter of the building with gaps for a porch, gates and other outbuildings. The structure consists of several layers, each of which is responsible for a specific function. There are several options for making paths along the house. The most simple to manufacture and practical in operation is the blind area made of concrete.

The need for construction

The construction is necessary for the following reasons:

- Drainage of storm and melt water from the supporting structures of the building. Limiting the contact of the foundation with aggressive substances in the ground.

- Creation of a heat-insulating layer that prevents freezing and heaving of the earth. Creation of comfortable conditions for staying in the basement.

- Use as a path on which you can walk and roll a wheelbarrow. With sufficient thickness, the concrete blind area around the house can be used for parking a car.

- Giving the building a spectacular, attractive and finished look.

When choosing a concrete blind area device, you should give preference to the most durable, reliable and durable options.

Concrete blind area device

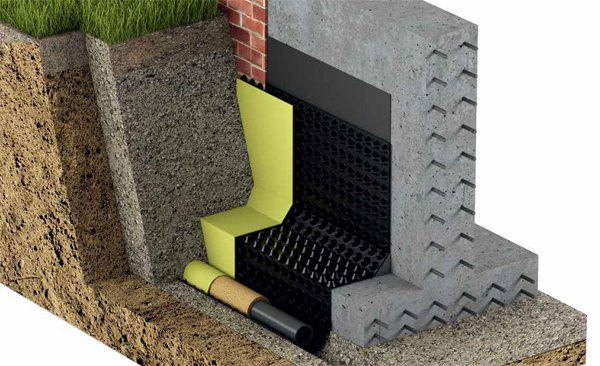

The building codes and regulations set the parameters of this structure:

- Level above ground. Regardless of the thickness of the concrete, it must be at least 50 mm to prevent water contact with the walls of the building.

- The width of the line. It cannot be less than 120 cm. A size is laid that exceeds the level of the roof by 40 cm or more.

- Thickness. It is determined by the expected load that will act on the structure. For a pedestrian, it is 5 cm, if he is with a heavy wheelbarrow - 7-8 cm, and for a car - 15 cm.

- Bias. It is attached to ensure rapid flow of water towards the ground or drainage system. It is 2-3%, it is not worth doing more, as the risk of slipping increases.

- The gap between the blind area and the wall. Depending on the climate, it is taken in the range of 10-20 mm. Do not leave it open. A shuttering board is inserted into the gap or filled with facade sealant.

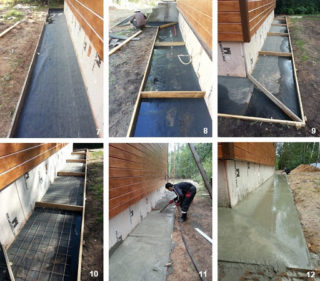

- Drainage system. Should be at least 200 mm wide and 100 mm deep with a perforated pipe laid inside to drain water from the building.

The technology for manufacturing the blind area is selected based on the type of soil, the depth of its freezing, the architecture of the building and the prevailing climate.

Varieties of blind area

There are several approaches to arranging the blind area, but in all cases, its performance is at the forefront, and only then the issues of price and attractiveness are considered.

During the construction process, the following materials can be used:

- Paving slabs. Hardware stores can offer stone pavers, cement, rubber, plastic, and resin based products. Considering that the sand-filled joints between the tiles allow water to pass through, a waterproofing gasket is laid under them.

- Concrete. The material is strong, durable, resistant to moisture and temperature extremes.During the construction process, a solution of its own or factory preparation can be used. To improve the quality of the mixture, dyes and plasticizers are added to it.

- Asphalt. It is extremely difficult to prepare, and even more so evenly lay this substance. Renting a truck and a roller is so expensive that it doesn't cover the benefits of coverage. One should also take into account the peculiarity of asphalt, which becomes soft in the heat and exudes a pungent smell of bitumen.

- Crushed stone. It is used as a base for laying natural or artificial turf. A waterproofing fabric is rolled out under the stone, which drains water seeping through the coating. Such a blind area looks interesting and picturesque, but requires special care.

When planning construction, it is allowed to combine coatings to achieve the best visual effect.

DIY concrete blind area manufacturing technology

For work you will need:

- concrete mixer, welding, grinder;

- pliers;

- shovel, hammer, ax;

- rammer;

- putty knife;

- hacksaw;

- tape measure, level, cord.

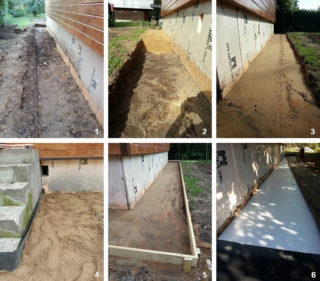

- Marking up. Performed taking into account the space required for the formwork.

- Digging a pit. The depth should be between 30-60 cm, depending on the degree of thermal insulation. The bottom is leveled and well rammed. You should immediately make a bias.

- The sand pillow is filled up. The material is wetted, compacted and leveled.

- Waterproofing is being laid. Roofing material or several layers of dense polyethylene is suitable. When building in cold climates, foam boards are added.

- Installation of formwork, which will at the same time serve as guide beacons.

- Reinforcement. Each knot is secured by welding, wire or plastic ties. The frame rises 2 cm from the base and is rigidly fixed.

- Filling the blind area. This is done in stages, by continuously filling each compartment with a solution. After pouring, the surface is leveled with a rule and a spatula.

It takes 28 days for the concrete to fully cure. During this period, the material must be watered and covered with foil.

Destruction protection and repair

Concrete is prone to deterioration under the influence of moisture and soil pressure. To make its surface stronger and more airtight, you can use deep penetration impregnation, water repellent and liquid glass. The ironing procedure gives a good effect, but for this you need to rent special equipment. To protect the edges of the tape from chips, it is advisable to install concrete or stone curbs. It is better to replace wooden expansion joints immediately with rubber gaskets, which have better elasticity. Sometimes ceramic tiles are placed on the blind area, which protects it from moisture and abrasion.

Most often, cracks appear on the tape. Minor defects are simply rubbed over with sealants and fillers. Larger gaps are widened, primed and filled with cement mortar. Large chips and sinks are cleaned of dust and debris and poured with concrete, followed by leveling and priming. The delamination is eliminated by a mixture of water, cement and liquid glass. After strengthening the surface, it is leveled with mortar or tiled.