When planning the construction of a house, you need to decide what building materials you need. We will have to compare, contrast and analyze the advantages and disadvantages of various options, get acquainted with their characteristic technological processes. Foam concrete blocks have recently become widespread in the construction of low-rise country houses.

- Material characteristics

- Manufacturing technology

- Dignity

- disadvantages

- Choosing a foundation for a foam block house

- Types of foundations

- Influence of soil on the choice of foundation

- Calculation of foundations

- Calculation of the area of the base of the foundation

- Calculation of the width of the foundation tape

Material characteristics

Foam concrete blocks (foam blocks) differ from traditional building materials used for masonry walls, manufacturing technology and a number of positive qualities inherent only to them.

Manufacturing technology

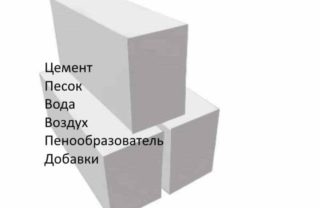

According to the existing classification, foam concrete is included in the category of cellular concrete. During its production, any foaming agent is introduced into the sand-cement mixture. The latter is obtained using rosin, bone or skin glue, caustic soda, etc. as the main material.

In addition to substances of natural origin, synthetic substances can be used as a foaming agent. However, blocks made from such foam concrete have dubious characteristics and can harm human health.

- fine river sand without clay impurities, the moisture content of which should not exceed 5%, the quartz content is not less than 75%;

- Portland cement, on the brand of which the density of the resulting blocks depends (M-400, M-600, D-400, etc.);

- soft purified water;

- foaming agent PB-2000, SDO-M, etc.

Sometimes, VSM fiber is added to the cement, which makes it possible to increase the compressive strength of foam blocks by 25%, and fly ash, which saves up to 1/3 the amount of cement in the mixture.

Theoretically, the technological process for the manufacture of foam blocks consists of the following operations:

- mixing of components;

- foaming agent input;

- pouring the resulting concrete mixture into prepared forms;

- keeping the mixture in molds until the desired strength is obtained;

- quality control of finished blocks.

As a rule, foam concrete blocks are manufactured in an industrial environment and have all the necessary quality certificates confirming their technical characteristics. However, if necessary, their production is easy to organize on the site allocated for the construction of a country house.

Dignity

- The high strength of foam concrete makes it possible to erect 3-storey houses from blocks without problems.

- The low density of foam concrete, comparable to the density of wood, does not exert high loads on the foundation of the structure.

- The low thermal conductivity of foam concrete retains heat well in the house, even without additional thermal insulation of the walls.

- The porous structure of foam concrete blocks has excellent sound insulating properties.

Foam concrete blocks have high refractory properties even when exposed to open fire.

disadvantages

Foam concrete blocks are not without disadvantages:

- The low bending strength, together with the relative fragility of the blocks, requires laying a rigid foundation when erecting walls.

- The high vapor permeability and water absorption of foam concrete blocks makes it necessary to protect the walls with an additional layer of waterproofing. When decorating the walls, you will have to use special materials.

The appearance of the blocks and their irregular shape leaves much to be desired.

Choosing a foundation for a foam block house

The foundation for a house made of foam blocks must withstand the walls and keep them intact for a long time.

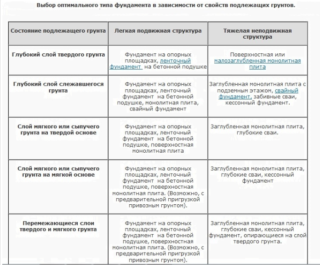

The choice of a foundation for a foam block house involves an analysis of the type of soil, the depth of its freezing, the level of groundwater, the weight of the structure being erected and other equally important indicators.

Types of foundations

When building houses from foam blocks, three types of foundations are usually used:

- Slab - a monolithic reinforced concrete slab located under the entire area of the house.

- Belt, is a reinforced concrete strip that runs along the perimeter of the entire house. The tape is also laid under all the walls of the structure.

- Columnar - requires pillars located at all corners of the building, at intersections of walls and where an increased load is expected.

The main factor affecting the choice of foundation is the type and condition of the soil on the site.

Influence of soil on the choice of foundation

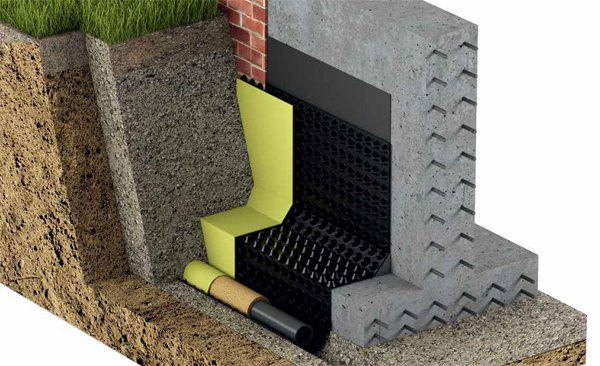

If the soil on the site is slightly loose, the groundwater does not rise above 2 meters and the depth of freezing of the soil is no more than 1 meter, a strip foundation can be built for the foundation of a house from foam blocks. In some cases, it will be quite enough to lay a shallow monolithic tape.

If the soil in the area is heaving and the water table is high enough, it is not advisable to lay a strip foundation. In this case, you cannot do without arranging a solid drainage system to drain water. It is better to opt for a monolithic slab. It can be made in the form of a slab foundation with stiffeners or an ordinary slab with a thickness of at least 40 cm under the entire structure.

The use of a columnar foundation, on which it will be possible to lay foam blocks, is possible only when the distance between the posts is reduced to a minimum and accurate calculations are carried out.

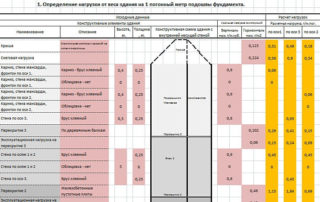

Calculation of foundations

The main function of the foundation is to distribute the load created by the structure under construction on the ground. When choosing a foundation for a house made of foam blocks, one cannot do without a careful calculation of its characteristics. This will protect the foundation and the structure being erected from cracks and deformations. The service life of a residential building depends on how competently the foundation for foam blocks will be laid. In the course of work on the design of the foundation, it is necessary to carry out:

- geo-survey of the building site;

- calculation of loads created by the structure of the house on the foundation;

- selection of the type of foundation and the material from which it will be made;

- calculation of geometric dimensions;

- preparation of a cost estimate.

It is best to entrust the performance of these works to a specialized organization that has a certificate for carrying out such works. A large amount of data is required for calculations:

- the size of the structure and its mass;

- house layout;

- relief of the site allocated for construction;

- climatic conditions;

- depth of groundwater;

- bearing capacity of soil, etc.

All calculations are carried out according to complex formulas, taking into account the coefficients given only in the tables of regulatory documents.

Calculation of the area of the base of the foundation

The base area of the foundation is calculated by the formulaS = Yn * F / Yc * Rowhere:

- S - the area of the base of the foundation;

- F - the total mass of the building;

- Ro - the value of soil resistance;

- Yn - coefficient of reliability;

- Yc - additional factor of conditions.

Ro can vary from 1.0 (lamellar clay) to 1.3 (sand), the Yn coefficient is taken to be 1.2.

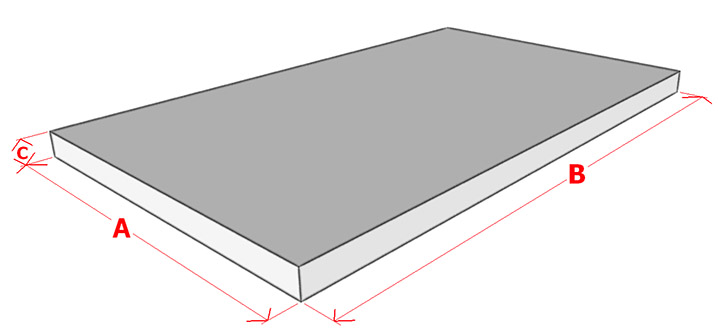

Calculation of the width of the foundation tape

The width of the foundation tape is calculated based on the bearing capacity of the soil and the weight of the structure being erected. In this case, the minimum value of the base of the foundation is determined by the formulaB = kP / (L * Ro)where:

- B - width of the base of the foundation (cm);

- P - total weight of the house and foundation (kg);

- L - the length of the foundation tape (cm);

- k - safety factor (as a rule, it is taken equal to 1.3);

- Ro - soil resistance (kg / sq. Cm).

The strength of the monolithic foundation tape is increased by expanding it at the very base. This will increase the area of support of the foundation on the ground.