Alkalis, salts and acids trapped in the soil have a destructive effect on underground building structures and communications. Over time, the material loses its strength, voids are formed under it, the building itself gradually comes into an emergency state. The blind area of the foundation allows you to protect it from dampness and give the entire structure a representative and finished look. There are many options for arranging this structure, involving the use of certain materials and the use of different technologies.

The need and device of the blind area

You can make a blind area at any stage of the building's operation, but it is better to fill it immediately after the end of the basement level shrinkage. The longer the soil near the house is open, the more water and plant seeds will get into it. Their germination is fraught with the need for regular weeding, and the likelihood of root damage to the base of the house. If you correctly make a blind area around the house, it will reduce the load on the drainage system and the likelihood of soil freezing below the foundation level.

The device of the blind area is quite simple to easily do it yourself.

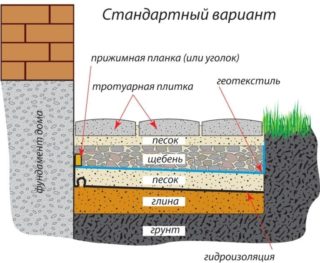

The structure consists of the following elements:

- Substrate. Serves to prevent the germination of grass and shrubs, as well as to protect the structure from erosion by ground and melt water.

- Adding. It is a layer of friable material. The pillow is designed to create an amortization level that dampens soil pressure when it freezes and is soaked in water.

- Steel frame. It is made in the form of a flat or volumetric lattice from a rod or reinforcement. Serves to impart rigidity and elasticity to the structure.

- Curbs. They perform the function of formwork when pouring, prevent spreading of mortar. Protect the edges of the structure from chipping and cracking.

- Insulation. Warming is carried out in order to prevent freezing of the soil in the area of the blind area. Materials are used which are resistant to moisture.

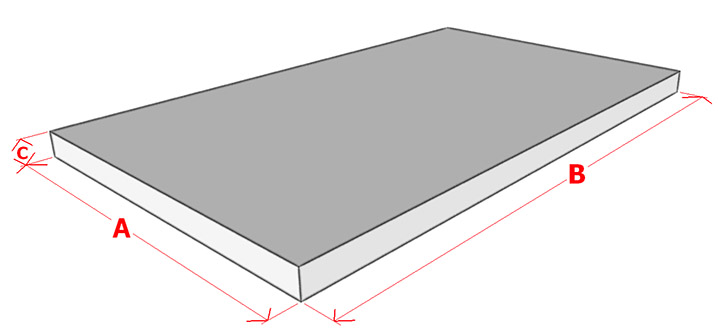

- Concrete slab. Depending on the purpose, it is made 5-15 cm thick. At a minimum level, it can withstand the weight of a person with a wheelbarrow. The slab of maximum thickness is used as a parking area.

Externally, the blind area is a wide step located along the perimeter of the building. The structure is given a slope of 2-3% in the direction from the walls. The size of the step in accordance with SNIP should be at least 80 cm when the roof projection is exceeded by at least 20 cm.

Functions and tasks

Private construction is associated with high material costs, since high-quality materials and equipment cost a lot of money. However, you should not save on arranging the blind area. This decision can lead to costly overhaul of the base of the house within a few years after its construction.

The concrete slab around the house has the following functions:

- protection of the foundation from moisture;

- prevention of soil erosion near the house by a stream of rainwater;

- giving the structure a complete appearance;

- creation of a pedestrian path for walking and moving small loads;

- additional heat-insulating layer.

As a walkway in winter, the slabs can be used in buildings of low height.Remember that falling snow or icicles from the roof can cause injury or even death.

Materials and technologies for the construction of the blind area

To work, you will need the following set of tools and accessories:

- concrete mixer;

- grinder, welding machine;

- hammer, ax, hacksaw, shovel, pickaxe;

- pliers, screwdrivers;

- level, tape measure, rule;

- rope;

- rammer;

- putty knife.

- cement, sand, crushed stone;

- plasticizer;

- geotextile fabric;

- dense cellophane or roofing material;

- sealant for filling damper joints;

- formwork boards;

- hardware (nails, screws);

- reinforcement or finished steel grating.

The production of the blind area should be carried out in the warm season, when the soil on the site dries out and settles after the winter heaving. Last but not least, you need to buy cement, as it has a limited shelf life. Everything else can be purchased in advance.

Preparing the fill

Before construction, it is necessary to make a competent and detailed drawing. This document will help to calculate the materials and determine the sequence of work. First, there is a preparatory stage, which consists in arranging a pit for installing a blind area.

This activity is carried out in the following sequence:

- Marking on the ground. Performed with a tape measure and rope on stakes.

- Removing the top grass layer of the soil. It can be used for patching up damaged areas of the lawn or for landscaping.

- Digging a trench. Depending on the degree of heaving of the soil, the depth is 15-40 cm. Giving the bottom a slope. For this, a shovel and a level are used. At 1 m of the bottom of the ditch, there should be a difference in height within 2-3 cm.

- Soil compaction. You can use a manual rammer, which is a log with handles. If the work area exceeds 50 m², it is advisable to rent a mechanical vibrator.

- Laying geotextile fabric. A more practical and reliable option is roofing felt. Both materials are laid in strips with 15-20 cm of edges at the joints. Geotextiles are glued with aluminum tape, and roofing material is held together by tar. The edges of the material must be brought onto the wall and glued to it. This will exclude the possibility of water leakage under the stove when washing the walls or forming condensation on them.

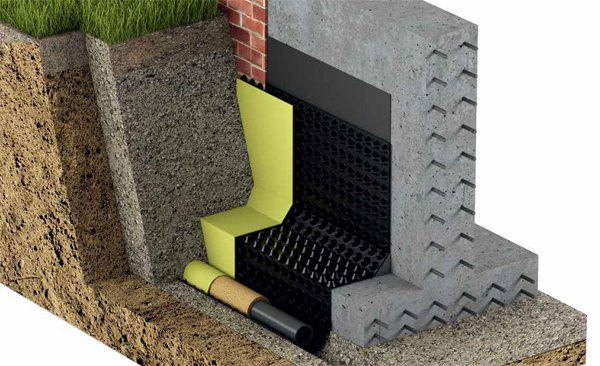

- Warming. Extruded polystyrene sheets are best suited for this. The material has low thermal conductivity, sufficient strength and elasticity to withstand ground movements. Underestimation of this stage leads to soil freezing and destruction of the blind area. A warm foundation will last longer without maintenance and major repairs.

- Arrangement of dumping. It consists of layers of fine gravel and coarse sand. In heaving soils, the height of the pillow can reach 30 cm. On solid soil, 15 cm is enough. The dump must be carefully leveled, spilled with water and tamped well. The uniformity of the load acceptance from the concrete tape will depend on this.

- Formwork manufacturing. The best option are 20 mm boards, which at the same time prevent the solution from spreading and serve as fill level beacons.Planks are installed along the walls and across the tape every 200 cm. Subsequently, these lintels will act as a shock absorber during the thermal expansion of concrete. If you plan to leave them, the wood must first be treated with an antiseptic and any hydrophobic agent. Another technology assumes that after the solution hardens, the boards will be taken out, and the openings will be filled with polymer sealant.

- Frame fabrication. If you plan to use the blind area as a footpath, you can take a ready-made mesh with a mesh of 30-50 mm from a rod of 6-8 mm. For transport, the base must be stronger. Here it is better to use a volumetric frame made of 10-12 mm reinforcement. The rods can be fastened to each other by welding, wire or plastic ties.

The final stage of the preparatory work is to check the strength of the assembly of the assembled structures. All nodes must be reliable and stable, since concrete creates a high load on all surfaces.

Rules for concreting the blind area around the house

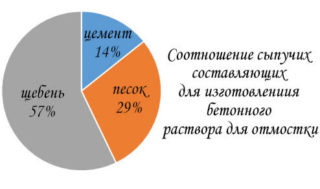

Recommended mix composition:

- cement M400 - 1 part;

- fine or medium-sized sand - 3 parts;

- large or medium crushed stone - 4 parts;

- water - 1 part.

The kneading process is step-by-step. First you need to mix water and cement until a homogeneous solution is obtained. Then sand is poured and, last of all, the aggregate.

Step-by-step instruction:

- Wetting the formwork and bedding. Wet wood does not draw water out of concrete, thereby ensuring the consistency of its composition and high-quality hardening.

- Mixing the solution. It must be poured from one of the lower corners of the formwork so that the concrete under its own weight fills all the cavities. After filling each cell, the procedure is suspended and the solution is leveled with a rule and a spatula.

- Making an ebb for a drain. This thickening is necessary to prevent the slab from thinning under the influence of rainwater pouring on it.

- Concrete hardening. This requires at least 28 days at an air temperature in the range of + 15-25 ºС. The slab should be covered with kissed and moistened daily to prevent cracking.

After complete crystallization of the material, its surface can be treated by impregnation with simultaneous polishing. This will give it extra strength and an attractive look.

Common mistakes when arranging a blind area

Mistakes are made at almost all stages of construction.

The most common are the following:

- Weak tamping of the bottom of the pit and dumping. As a result, uneven shrinkage, cracks and depressions appear on the tape.

- Using construction debris when creating a pillow. Such savings on disposal and materials are fraught with moisture ingress into the voids, followed by heaving and destruction of the slab.

- Lack of bias. This leads to the fact that melt and storm water flows down to the walls, causing them to get wet, the development of fungus and mold. With a loose damper joint, moisture also penetrates to the foundation, which leads to its accelerated wear.

- Neglect of expansion joints. When heated, concrete expands, and if there is no room for this, then the slab bursts. The seams should be at the junction of the slab and walls, as well as across the slab.

It is not allowed to use dirty water, sand and stone to prepare the solution. Admixtures from clay and water significantly reduce the quality of concrete.

the mistake is that your blind area touches the foundation, they should not touch each other between them there should be a gap between them is poured either with bitumen or penoplex and sealed

I added Basf outdoor additive to concrete

Have you tried to waterproof the foundation with a storm sewer under the ground? What century? What are the blind areas? Look around people! Learn to learn and build in a modern way!

Exactly!!!! All the advisers on the blind area are banal shabashniki with the aim of robbing the customer to the bone with moldy advice. 5 years "soft" blind area around the cottage of pebbles with drainage pipes under it, the maximum that happens is sometimes a stalk of some kind of grass pull out of it ...

Gregory, storyteller :)