The beginning of the construction of any building, regardless of its purpose, shape, size and weight, is the arrangement of a solid and reliable foundation. This structure is designed to give the structure stability, prevent its deformation, protect it from moisture and cold emanating from the ground. The pile-screw foundation belongs to the category of structures that are widely used in private and industrial construction in all climatic zones and areas with complex soils. The pile foundation is a set of supports immersed in the ground, rigidly united into one common frame. This technology has its pros and cons, features and varieties. The decision is made after evaluating all the factors associated with a particular construction project.

Reasons for using pile foundations

In private construction, the foundation on screw piles is not used as often as tape counterparts. But in some cases, this design is the only option.

Reasons for using a foundation on piles:

- Weak ground. This category includes moisture-saturated and unstable loess-like soils, clays and loams, quicksands, salt marshes, silts and sapropels. Such bases are soft and cannot be the basis for a heavy structure. The piles are sunk into the ground until they reach dense layers that can withstand high loads.

- Extremely dense and heavy soil. The pile foundation is equipped in order to reduce the volume of expensive and time-consuming earthworks, and to reduce the consumption of building materials. Compared with the arrangement of a shallow tape, the installation of supports will take 3-4 times less time and concrete.

- Building a house on a slope. Here, leveling and backfilling may not be possible, unreasonably expensive and unreliable in the future. With the help of supports, you can compensate for height differences up to 200 cm, and when using additional elements - up to 400 cm.

- Construction near the reservoir. Raising the house above the ground will help protect it from flooding that occurs after heavy rainfall and melting snow.

Sometimes such a decision is made when erecting light frame structures, for which a heavy and powerful foundation is not needed. In such cases, the supports are installed at the corners of the timber frame and under the supporting risers.

Application area

Stilt houses have a wide range of uses due to their many inherent advantages.

The base is used for the construction of buildings of this type:

- residential buildings;

- baths;

- summer cottages;

- sheds;

- pantries;

- workshops;

- temporary huts for workers;

- outlets;

- cash desks;

- Checkpoint.

The decision to build houses on poles is advisable under the following conditions:

- high groundwater level;

- heaving soils, which, when frozen, increase in volume up to 10-12%;

- lowland, regularly flooded by storm and melt waters;

- freezing depth from 150 cm, when pouring a reinforced concrete tape is associated with high costs;

- slopes that are expensive or technically impossible to level.

In all cases, the involvement of specialists is required to determine the type of columns, the location and depth of their laying.

Pile foundation options

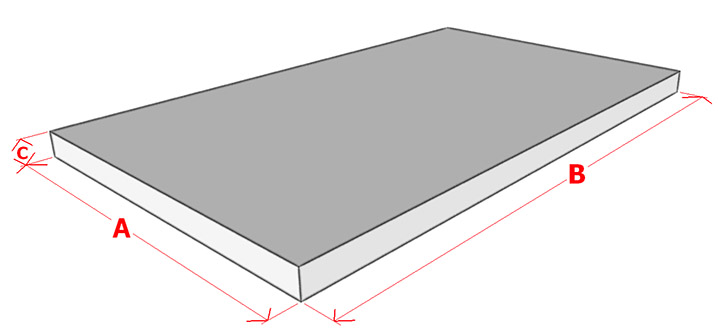

Foundation piles are rods pointed on one side, immersed in the ground until the depth specified by the project is reached. Products can be of round or square cross-section, they are immersed in the ground in finished form or are made directly on site. Supports are made of wood, steel and reinforced concrete. Construction schemes involve the installation of piles one by one, by bushes and fields. The main difference lies in the technology of submerging the poles into the ground.

Driven piles

The products represent a powerful reinforced concrete structure with pre-stressed reinforcement. Lowering into the ground is carried out using a mechanical hammer or press. Under the influence of high pressure, the pillars are driven or pressed into the ground. Stability is achieved by compaction of the soil under and on the sides of the rod. Many private developers are against this technology, as it is associated with strong vibration, and in order to hammer the supports, you need to rent expensive equipment.

Reinforced concrete piles are of the highest strength and reliability. Products do not corrode, their service life is practically unlimited. The downside is that reinforced concrete products cannot be removed from the ground for reuse or for arranging a new foundation on the site.

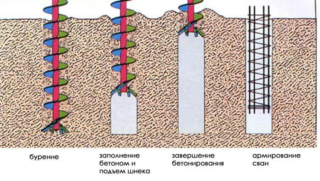

Bored piles

Products of this type are most often used in private construction. The reason is that they can be assembled by hand, without the involvement of heavy equipment and the purchase of expensive equipment. The technology consists in the step-by-step assembly of the rod right at the site provided by the project. First, a well is dug or drilled. If the soil is fragile, a formwork or a casing pipe is inserted into it, but first the bottom is covered with a layer of sand. The next step is knitting and lowering a three-dimensional steel frame of a triangular or square section into the hole. Finally, the well or pipe is poured with concrete. The disadvantage of ramming technology is that there is no soil compaction under and around the pile. Based on this, the possibility of its lowering under load cannot be ruled out.

Screw piles

With high efficiency and affordable cost, products of this type have a fairly simple device. They consist of a metal tube, the lower end of which is pointed and equipped with blades. The other end has holes for threading the lever. When working on soft ground, supports with blades are used along the entire length. Screwing in is carried out manually or using a mechanical gate. After reaching the desired depth, the excess part of the pipe is cut off, concrete is poured into it. Then a metal head is welded to the pile, to which the grillage is attached in one way or another. Thanks to the blades, the support is firmly held in the ground, without dropping even under heavy load. Choose products carefully, paying attention to the quality of welds and anti-corrosion coating. The most expensive but most reliable option is to purchase stainless steel products.

Rules for choosing the type of foundation

To build a strong, stable and durable pile foundation for a house, it is necessary to draw up a competent and thought out plan to the smallest detail. The structure of the structure will depend on a number of factors:

- support material;

- method of immersion in the ground;

- depth of soil freezing;

- ground water level;

- the estimated weight of the building together with the property and people in it;

- terrain landscape;

- architectural features of the house;

- soil structure;

- nearby buildings that can affect the weakening of the base;

- drawing of previously laid engineering communications;

- type and method of grillage fastening.

The general rule is to install piles at the corners of the building, under load-bearing walls and fragments that create an increased load-bearing load. These are kitchens, bathrooms, heating boilers and boilers. Supports in private construction are placed at intervals of 150-200 cm around the perimeter of the building and up to 400 cm under internal partitions.

Screw piles are considered the best option for construction on quicksands and slopes. Products can be lowered to a great depth without the use of special equipment, which is not always able to get to the place where the supports are installed.

On dense soils, it is advisable to use hammered and bored products. Even if you have to rent equipment, the costs will be paid off by the high speed of construction and the quality of work performed.

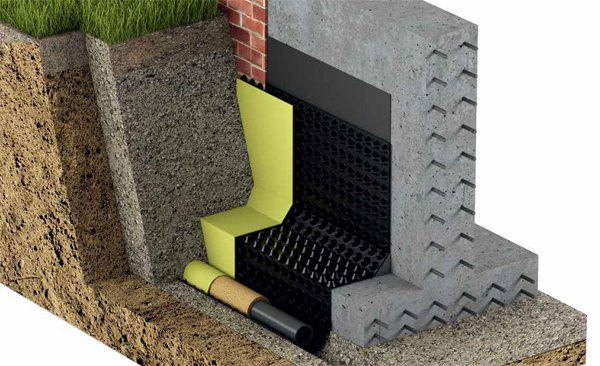

When planning, you should pay attention to the choice of the type of grillage. These structures connect the pile heads and provide an even distribution of the vertical load. Low grillages are laid below ground level and take on some of the weight of the house. High-type structures are located above the ground and are only a link between the supports. According to the installation options, prefabricated and monolithic grillages are distinguished.

The main stages of work on laying the pile foundation

The use of driven piles involves the use of special equipment, which is not always acceptable and technically possible in private construction. When building cottages, houses, summer cottages and outbuildings, the choice is often made in favor of products of the screw and bored type. As with any construction, the initial stage is the study of the site, the comparison and analysis of the data obtained, the preparation of project documentation. Then the active phase begins. It is better to conduct it in the warm season with dry weather.

Step-by-step instructions for building a pile foundation with your own hands:

- Decide on the construction site. Clear it of grass, shrubs, trees and debris. Mark and dig in the area where the waste will be stored.

- Carry out the markup. Check the correspondence of the drawn lines to the project, the accuracy of keeping right angles.

- Remove the topsoil. If a low grillage is chosen, dig a ditch with the expectation that a cushion of sand and gravel will be poured into it. Level and compact the bottom of the ditch.

- Screw in the screw piles, align them along the upper cut. Make holes for bored supports, fill and tamp sand in them, lower the formwork ..

- Make a formwork for the grillage. Wood planks are best suited for this. Under the upper grillage, you need to install props at a distance of 200-250 cm from each other.

- Tie the frame for pipes and formwork, connect the metal parts of the piles and grillage.

- Prepare and pour concrete. First, the pipes are filled, and then at minimum intervals for mixing the next batch - the formwork for the grillage. Level the screed surface.

- 4 hours after the end of the pouring, cover the structure with cellophane. Moisten concrete with water every 6 hours throughout the day to prevent cracking.

The foundation reaches its full strength in 28 days. After the end of this period, you can start insulation, waterproofing and finishing work.

Advantages and disadvantages

The advantages of this design:

- applicability to all types of soil except rock;

- the ability to carry out the installation on their own, without renting special equipment;

- the speed of the preparatory work and the construction itself;

- the technology involves the installation of a grillage before the end of concrete hardening in pipes;

- creation of a solid support due to blades on screw models and concrete overflow in the ground for bored products;

- cost savings due to the minimum amount of materials used, the reduction or absence of excavation.

A separate support is not stable and reliable. In order for the foundation to be strong, it is necessary to connect several piles with a grillage, and this is additional effort and expense.

Construction can be carried out only after conducting a soil survey, which can only be carried out in a qualified manner by specialists.

Piles and material for their manufacture should be purchased from trusted suppliers so as not to run into a fake.