A drainage well is necessary to reduce the level of flood waters and drain wastewater from the personal plot in a storage tank or into the ground. This protects buildings from damaging effects and prevents waterlogging of the land. The construction of a drainage well made of durable concrete rings can be completed within one day. The design will last a long time and will not require significant material costs.

Advantages and disadvantages of structures made of reinforced concrete rings

- Increased strength. The devices are immune to strong horizontal and vertical loads caused by seasonal soil mobility.

- Integrity of the structure. Sealing is provided by special ledges along the edges of the rings and the use of seals. In excessively moving soil layers, the fragments of the mine are connected by welding.

- Immunity to aggressive influences. Concrete is resistant to acid and alkaline components in the soil. Also, it is not subject to destruction under the influence of plaque or silt. Neither mice nor insects can spoil reinforced concrete.

- Construction speed. With the use of an excavator, the installation of the well will take only half a day.

- Ease of service. The process includes the systematic replacement of the filter and the timely cleaning of the walls of the well from deposits.

- Long service life.

The disadvantages include a large mass of rings, which involves the hiring of special vehicles equipped with units for lifting and moving. It becomes necessary to equip the entrances to the installation site.

Varieties of concrete drainage wells

Types of drainage well systems:

- collector (accumulative);

- filtration (absorption);

- observation (inspection).

The first option is suitable for installation on loamy soils that cannot absorb a significant amount of water. It is used when it is impossible to dump excess liquid outside the territory. The device of a sealed collector assumes the flow of wastewater from the drainage system into it with its subsequent use for technical purposes.

Two or more units can be located over a large area. When building one well, several drainage lines are brought to it. Usually, plastic products with a cross section of 570 mm or more are used. The rate of filling the tank depends on its volume, and it is collected in the lowest place so that the connected pipes are located above the tank itself.

Absorbers are installed if it is impossible to remove moisture from the site outside of it or into the citywide sewer network. Their design features imply a volume of wastewater not exceeding a cubic meter in 24 hours. The depth of the structure should be more than 2 m. Broken clinker is poured on the bottom of the device or a slag, gravel layer of about 300 mm thick is created, which helps to absorb moisture. The well top of the well is covered with geotextile material and covered with soil. Most often, filtration wells are installed on sandstones and sandy stones. These types of soils absorb moisture well.

Inspection devices are used to identify and remove blockages in the lines. Moisture does not collect in them. Installations with a small cross-section (up to 46 cm) are designed for washing pipes. Workers descend into wide wells with a diameter of up to two meters to carry out manual cleaning. Observation structures are erected at the joints of pipeline sections or on long straight lines.

A type of inspection type wells are rotary structures. They are erected at the intersection of pipe sections, at the corners and bends of communication lines.

Preparation for work

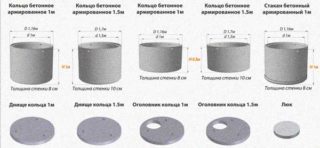

Products are produced in different standard sizes. Diameter can be from 0.7 to 2.5 m, height - from 0.1 to 2.5 m: the range of options is wide.

For a drainage well, products are usually chosen with a height of half a meter and a section of 0.7-1.5 m. Their weight depends on the size and can be from 200 to 900 kg.

The absorption devices are placed on a loose filter pad. It must be made at least half a meter high from sand and gravel and crushed stone. The arrangement of the pillow will be required even when the lower reinforced concrete ring is equipped with an integrated filter bottom.

Accumulators and inspection devices are installed on the bottom plate or on the cement screed. Previously, the bottom of the pit must be tamped. The rings are placed one on top of the other with strict observance of the vertical. The abutting areas are sealed with bitumen mastic or liquid cement. In order for the prefabricated elements to be securely fixed, they are connected from the inside with metal ties so that one edge of the plate is held on the upper ring, the other on the lower one.

Installation steps

There are two ways to assemble a drainage well. If the ring is wide, and time permits, a worker with a shovel gets inside it and digs out the soil from the inside. The concrete part gradually sinks into the ground. But this method is laborious and is not possible for all types of wells. A better structure will turn out if you attract special equipment to create a well pit and install reinforced concrete parts.

How to make a drainage well - instructions for devices from concrete rings:

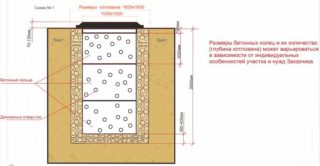

- A pit of the required diameter and depth is pulled out so that the rings can easily pass into it.

- A gravel-sand cushion is arranged at the bottom. Its thickness depends on the type of structure.

- The first ring with the bottom is placed on top. If the latter is not available, a cement screed will be required.

- Subsequent reinforced concrete parts are installed on top of the previous ones. The joints are sealed.

- After installing the upper reinforced concrete element, holes of pipe sections are made in it, if such inputs are not provided for by the design of the ring.

- The ends of the communication elements are inserted into the holes, the seams are carefully filled with cement or bitumen.

- The gaps between the walls of the pit and reinforced concrete products are covered with a sand and gravel mixture.

The top ring is covered with a lid. It can be made of concrete, but metal or plastic models are more often used, since they are much lighter.

Well reinforced concrete rings are chosen in accordance with the type of soil, climatic characteristics and the type of drainage well. The cost of products starts at 700 rubles. The price depends on the dimensions of the concrete ring for the drainage well and the presence of additional design features. Also, the price fluctuates depending on the season, the brand of concrete and the manufacturer.

In winter, reinforced concrete rings can be purchased somewhat cheaper than in summer, since it is almost impossible to build a well in frosty conditions. But zealous owners of private houses take this factor into account and purchase cheaper products for future use.