High-quality drainage of storm / ground water is a guarantee of the durability of the building on the site. If proper action is not taken in time, over time the object will fail due to a violation of the integrity of a solid foundation. Concrete gutters are used as a ground / stormwater drainage system, the price for them depends on the volume, manufacturer, type of material from which the trays are made.

Advantages and Disadvantages of Concrete Gutters

Reinforced concrete trays have been used for stormwater drainage and drainage systems for over 100 years. The main advantages of the designs are:

- High resistance to stress. Polymer fiber is added to the composition of reinforced concrete products as a reinforcement, so the trays are capable of undergoing linear expansion loads.

- Anti-corrosion properties. Concrete does not rust or rot, even with long-term use.

- Resistance to aggressive environments. Storm runoffs with an admixture of reagents are not capable of damaging the walls of structures.

- Excellent resistance to temperature extremes. Even in severe frost, the concrete trays do not burst.

- Elimination of the risk of displacement of a powerful storm storm due to the impressive weight of communication.

- Environmental friendliness of products. Concrete gutters do not pollute the environment, do not emit toxins either into the ground, or into the atmosphere, or into storm drains.

- Competitive price of products. It is comparatively lower than cast iron trays and slightly higher than polymer ones (provided that polymer concrete gutters are purchased).

The relative disadvantages of reinforced concrete or polymer concrete trays include their weight, which requires special equipment for laying stormwater. Also, the disadvantages of products include a moderately rough inner surface of the gutter, on which fluff can form. In polymer concrete products, the walls are quite smooth.

It is possible to avoid the growth of silt and further blockage of the sewage system by regularly cleaning the communications, or by installing special sand traps during installation.

Types of concrete gutters

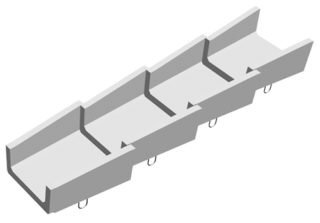

The classification of concrete gutters for draining water on the ground is based on several criteria. By the type of collector gasket, there are standard horizontal trays and products with a vertical weir.

By the type of destination, all reinforced concrete gutters are:

- Stormwater. They are used near construction sites and public places for high-quality drainage of rainwater.

- Culverts. They are used in the construction of gravity canals for groundwater disposal.

- Telescopic. Designed to remove excess moisture by the channel method from road slopes and bridges.

- Drainage. Used for installation of drainage systems from basements of buildings and basements.

- Edge. They are used for the installation of storm water along highways.

- Sewer. They are elements of a sewer collector.

When choosing the right type of gutters, you should also be guided by their load class. Depending on the purpose of the storm drain, more or less reinforced trays are installed. Divide them into classes:

- A15: intended for use on pedestrian sidewalks, cycle paths, in private garden estates.

- B125: used in small parking lots, roads with low traffic.

- C250: used for moderate traffic on the road or for domestic construction. The cost of such gutters is one of the lowest.

- D400: Applicable in large parking lots, high traffic roads and small industrial areas.

- E600: designed for the installation of a drainage system from railway tracks, large autobahns and highways, large industrial facilities.

- F900: The most powerful type of chute used for stormwater runways.

Also, all reinforced concrete trays are classified according to their shape:

- U-shaped;

- U-shaped;

- trapezoidal;

- parabolic.

To select the optimal concrete gutters for storm sewers, you should correctly calculate the estimated volume of rainwater waste. It is determined by SNiP 2.04.03-85 - each region has its own indicator of the volume of effluents per year. Only then is the cross-section of the trays selected.

The classification of concrete trays also applies to overall parameters. If the length of the products is 1 m as standard, then the internal section of the gutters varies within the range of 100-500 mm. The smallest are used for the device of a household storm drain.

Product cost

The actual price of reinforced concrete gutters varies depending on the region and manufacturer. However, on average, you can focus on the following cost:

| Tray dimensions L / W / H (cm) | Volume, m3 | Price rub / piece |

| 110/39/37 | 0,06 | 800 |

| 120/48/28 | 0,06 | 900 |

| 240/48/28 | 0,12 | 1 800 |

| 236,5/53/30 | 0,35 | 3 600 |

| 68/30/34 | 0,038 | 2 000 |

| 110/32/2 | 0,02 | 3 800 |

| 74/49/4 | 0,02 | 3 200 |

Laying steps

Installation of a household storm drain from reinforced concrete gutters can be done by hand. The main thing is to adhere to the basic principles of the drainage system. You need to follow these recommendations:

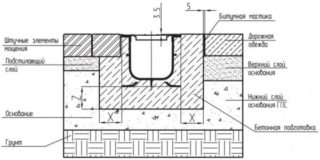

- Initially, a trench is prepared for the stormwater device. Its section and height should be 10-15 cm higher than the parameters of the gutters. The stock is later used to strengthen the walls and bottom of the collector. When digging a trench, the slope of the drainage system is taken into account at the rate of 5 mm for each meter of the length of the gutters.

- The soil at the bottom of the canal is well rammed and covered with a layer of sand 5 cm thick. The pillow is also carefully rammed.

- A layer of crushed stone 5 cm thick is poured on top of it. A thin layer of concrete mortar is already poured on top. After hardening, it will serve as a reliable support for the gutters.

- Trays are placed on the prepared base and securely coupled together using the groove-lock method. All joints are coated with acrylic / bitumen sealant.

- The walls of the installed storm drain are additionally fixed with concrete mortar on both sides.

- The finished collector is connected to the point of discharge / collection of rainwater.

- The last stage of installation is the installation of protective grilles. They can be made of cast iron, galvanized steel or polymer.

The level of the location of the finished drainage system should be below the level of the plane of the blind area, asphalt, roadway.

If you follow all the recommendations, self-installation of the rainwater drainage system does not cause difficulties. For handling heavy trays, you can use the help of a neighbor or hire a special technician. A ready-made concrete drainage system will last for decades without the need to change elements.