The professional sheet is supplied to Russia by Poland, Ukraine, Germany, South Korea, Finland, Slovakia. The material is in demand for roofing, walling, construction work. Gray graphite corrugated board is produced in different sizes, the thickness of the sheets ranges from 0.35 to 1.0 mm, the shade is classified according to the RAL catalog. The sheet has a deep gray color, matte surface without shine. There are many criteria for choosing.

Material description

Profiled decking is obtained from flat metal sheets by cold rolling on pressing equipment. The trapezoidal shape of the surface gives the material strength and aesthetic appeal. Manufacturers are guided by the technical specifications of the company and GOST 24.045 - 1994.

The professional sheet is produced in the form of high-quality galvanized panels or profiles with a protective polymer or paint-and-lacquer coating (GOST 14.218 - 1980 and GOST 52.146 - 2003, respectively). The material is marked with letters C, H, HC, which mean technical characteristics and scope. This division is conditional, since species from one category are used for other purposes. The numbers after the letters indicate the thickness, height of the waves, and the width of the sheet.

Types of corrugated board:

- With the letter C (wall). The material is used for finishing facades, installing internal and external partitions, arranging fences and barriers. Trapezoidal elements on the sheet have a height of 8 - 24 mm. Usually, the material is painted on both sides, and the thickness of the steel for production is 0.45 - 0.55 mm.

- With the letter H (carrier). Panels are used for the device of roofing, as the base of a flat soft roof, for the installation of non-removable load-bearing formwork of floors. The geometry of the profile includes auxiliary stiffeners, so the strength of this type is greater than that of the wall. The wave height is from 57 mm, and steel is used with a thickness of 0.55 - 1.5 mm.

- NS marking (non-existent-wall). The panels are used for the construction of fences and roofs; the walls of hangars and pavilions are made of them. The wave height is 35 - 44 mm, and the material is produced from galvanized metal with a thickness of 0.5 - 0.9 mm.

The length of the strip is made no more than 12 m, the required size is ordered individually. Some manufacturers cut the material in multiples of one meter, others make a gradation of cutting every 0.5 m.The useful width of the sheet fluctuates depending on the wave height, since standard strips of 1.25 m are used for production, less often - 1.0 m.

Despite the small thickness, the sheets are durable due to the corrugated surface. Builders move along the panels when laying the roof.

Metal profile gray graphite

There are 3 main color catalogs of profiled roofing material: RAL, YPS, RR. Most of all, manufacturers work according to the RAL standard, which is referred to as a generally recognized world standard.

Description of the category profiled sheet 7024:

- painted in dark gray color, deep, intense color;

- the characteristic appearance of the shade has become the reason why it is called not graphite gray, but is compared with wet asphalt, the name in the first version is used in the catalog;

- the color looks effective, which is why it is often used in private buildings and fences.

The catalog contains 213 shades, of which 38 shades are included in the "gray" seventh group, and several gray shades in the ninth.A simple count suggests that grays are the most common in production and use.

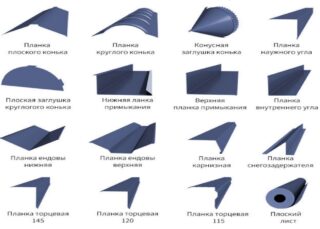

Manufacturers make additional strips, caps, corners for the graphite profiled sheet, in addition to this, they supply users with self-tapping screws to match the color of the material. U-shaped, fence and parapet strips, external and internal elements are produced. For a matte sheet, matte self-tapping screws are made so that they do not shine on a common plane. Hardware is made with a length of 35 mm (for the base) and 19 mm (for a metal profile) with a head for a hex key.

Advantages of RAL 7024 profiled sheet

As a result of high-quality coating, the graphite corrugated board acquires resistance to corrosion processes. Initially, galvanized metal is used, the durability depends on the thickness of the zinc on the surface of the workpiece. Some manufacturers have developed a better finish by mixing 95% zinc with 5% aluminum.

Positive characteristics of gray graphite profiled sheet:

- easily transfers loads, shocks, does not change shape under static and dynamic force;

- tolerates daily temperature changes in winter and summer;

- does not suffer from high humidity, rain;

- ultraviolet rays do not change the color intensity, over time the material does not fade, the surface remains intact;

- fungus and other harmful microorganisms do not develop on the plane of the roof, fence;

- shows resistance to scratches on the panel surface;

- shows good adhesion of the top protective layer to the substrate.

The addition of aluminum protects the ends when cutting the profile; for this, circular circular saws are used. At the same time, a thin layer of aluminum oxide is obtained at the edges, which simultaneously protects zinc and metal. An important criterion for the quality of sheets is the absence of lamination during cutting. When bending the sheet, each layer is bent together with the others to the required shape and does not crack.

The resistance of the coating to the formation of scratches and cracks is important during transport, storage and installation in the installation position. Often houses are exposed to aggressive chemicals in the atmosphere, for example, acids, alkalis. The polymer coating on the graphite-colored corrugated board protects the material from harmful effects, resists destruction.

The metal on the surface retains its original color for 30 - 40 years, it does not deteriorate, since the composition contains substances that trap UV radiation. Maintenance of a layer of graphite profiled sheet is almost not required, it cleans itself during the rainy season.

Characteristics of painted corrugated board

Before the discovery of polymer coating technology, black metal, roofing material, slate, and a soft roofing made of bitumen were used on steel. Polymer coated steel has supplanted these materials because it combines ease of installation with good performance. Graphite-colored corrugated board helps to create original design projects, it is distinguished by its plasticity, durability, which is important for private sector users.

Types of applied treatments:

- polymer paint layer with polyamide granules;

- primer layer;

- a protective layer of chemically treated zinc;

- metal base made of high quality steel;

- protective layer and high-quality painting of the reverse plane.

The versatile painted steel justifies the purchase and installation costs. The material goes through several stages of processing and painting in an automated production environment. Layers perform a specific function, therefore, the final properties of the product depend on their combination.

The cost of the painted profiled sheet exceeds the price of galvanized material by 10 - 15%. The coating on the surface is up to 0.2 mm thick, so the weight is not too different. Various polymeric materials are used for protection: plastisol, polyester, PVDF, pural. They differ in corrosion resistance and thickness.

Scope of application

In private housing construction, corrugated board 7024 is used for the construction of fences, fences. The gray color goes well with natural stone, red and white bricks, therefore, inserts between the posts of these materials are made of profiled sheet. The lightweight version of the fence is a strip of dark gray profiled sheet, fixed on supports from a metal pipe.

The walls of houses are also sheathed with sheets of wet asphalt color, but this color is not always suitable for solid cladding. It is successfully diluted with other lighter shades, thus obtaining a spectacular exterior of a residential building.

The façade should be lighter than the roof in order for the building to look attractive.

This color is also used in industrial and commercial construction. The dark gray color accumulates heat, so workers hangars and workshops are sheathed with sheets in order to reduce heating costs. The flooring is used on the roof, for the construction of functional partitions in working rooms. They are successfully sheathed with frame structures, for example, warehouses, change houses.