Decking is a popular material for the manufacture of temporary and permanent fences. This is due to the affordable cost, presentable appearance, the ability to build structures with your own hands. It is important to correctly calculate the fence made of corrugated board, so as not to overpay for surpluses and not to stop construction due to a lack of material.

How to calculate a fence made of corrugated board

In order to correctly calculate a fence from a professional sheet, you need to take into account many nuances of not only construction, but also of a social nature.

It is necessary to deal with the permitted height of solid fences for external and internal placement. From the street side, it can be up to 250 cm, and between neighboring yards it is limited to 70 cm. Adjacent structures are made combined, where the lower part is solid, and the upper transparent one is made of mesh, lattice or cellular polycarbonate.

The next factor is the type of foundation. It can be point - for each support separately, or tape - in the form of a closed reinforced concrete contour. The second option is more expensive, but more practical, since the entire structure is locked in a single foundation, which makes it much more stable and stable. The second reason for this choice is the impossibility of undermining by animals and intruders.

Another criterion that affects the calculation of the fence from corrugated board is its length. In any case, it should be around the entire perimeter of the site. The choice should be approached thoughtfully, distinguishing between presentability, practicality and the correct choice of installation technology. From the street side, more expensive sheets can be installed by placing them without a gap. At the back of the yard, where strength is needed, it is worthwhile to install sturdy panels with a simple but reliable cover.

Varieties of corrugated board

Priority can be given to the following types of panels:

- Curly. They have a monochromatic or patterned color. They are distinguished by the presence of peaks, waves or triangles along the upper edge of the fence. It costs 10-15% more than flat counterparts.

- Perforated. The many tiny holes provide excellent sound insulation and reduce the windage of the deck, which is important in areas with strong winds.

- Standard painted. The color range is very diverse, as well as the protective coating. Budget options are acrylic and polyester, but such panels will not last long. Expensive polydifluorionate and pural, which are the quality standard, will last at least 30 years.

- Decorative. The face layer imitates brickwork, cobblestone, cobblestone or torn stone wall. It looks expensive and representative, polymer spraying protects the metal from corrosion.

To calculate fences made of corrugated board with maximum accuracy, you need to remember about fasteners. For screwing the sheets, special self-tapping screws with a drill and a silicone washer are used. Average consumption of hardware is 10 pieces per panel. There is one nuance here: so that the sheets are not removed by intruders, you must use hardware with an anti-vandal head.

Material consumption depending on the method of fastening

The profiled sheet for the fence should be calculated so that, without prejudice to the aesthetic and protective side of the issue, there is a minimum amount of waste. The arrangement of the supports is matched to the parameters of the sheets. The standard is 120 cm in width and 200, 300 cm in height. The project is adjusted to these dimensions.

There are the following mounting options:

- Horizontally without post spacing. Here, it is optimal to take a distance between the posts of 270 cm, where the panels are overlapped by 15 cm in length and one wave (10 mm) in height. The result is a fence with a height of 190 cm when mounted close to the ground.

- Horizontally spaced for posts. In such a structure, we are not talking about closedness, therefore, gaps can be made 20-25 cm each. According to this plan, the supports are dug in at an interval of 2.5 meters, and two-meter panels are attached between them.

- Vertically without post spacing. The most popular technology for those who value privacy. The sheets are mounted on racks installed at a distance of 200 or 300 cm. The choice is determined by the wind loads of the region. When installing slabs with a width of 110 cm, 10 cm goes to the overlay, as a result, exactly 3 products go to the span, and the extreme ones are screwed on the supports.

- Vertically spaced for posts. Here, the optimal solution is to put 2 sheets with gaps on racks spaced 250 cm apart.

If the fence is made on the border with a neighboring site, where the height is limited to 70 cm, only options with a vertical method of fastening remain. It is better to take sheets 200 cm long and cut them into 3 parts, when the size of each is 66 cm. And the legality will be observed, and there will be no waste.

Guardrail supports and horizontal rails

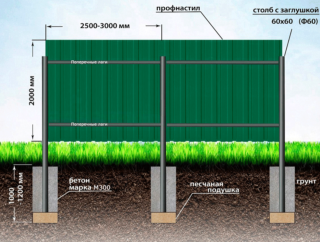

The most common option for the manufacture of supports are rectangular pipes with a cross section of 40x80 mm. For gates and wickets, more durable posts 100x60 or 100x80 mm will be required. The length of the profile is selected based on the height of the fence. For a fence of 200 cm, a length of 300 cm is needed, since the support is dug in at least a meter.

Wood is also considered as a material for supports, but experts do not recommend it. Raw materials are natural, environmentally friendly, easy to process, but this is also its weakness. The strength of the material is limited, and it itself is prone to decay. An alternative may be to use expensive varieties, but this is very expensive and not economically justified. If such a decision is made, you need to use a beam or log with a cross section of 100 mm.

The brick option is the most expensive and time consuming. When planning, it must be borne in mind that 56 bricks go to 1 meter of support. Plus, for every 1000 units, 70 kg of cement and 300 kg of sand are needed.

The veins between the pillars are made from a 40x20 mm pipe or a 100x20 mm board. For a fence with a height of 200 cm, they put 3 guides, for structures below, 2 crossbars are enough.