The scope of application of profiled sheets is wide. They are laid on the roof, the walls are sheathed with them, the flooring of the fence is formed and used as permanent formwork in the manufacture of ceilings. One of the factors that is taken into account in the design process of real estate objects is the weight of the corrugated board. This parameter is included in all calculations and allows you to accurately determine the technical characteristics of the supporting structures.

What is the mass of the sheet determined for?

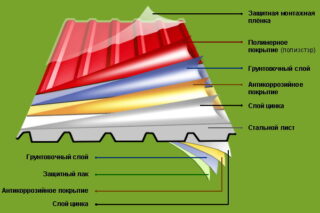

Profiled sheet is a rectangular panel, which is given a curly section. Waves of different heights determine the appearance of the slab and its resistance to mechanical stress. The material consists of an iron plate, zinc coating, paint and protective spraying. The thickness of each layer determines the flexibility of the sheet, its resistance to mechanical stress, moisture, abrasive substances and ultraviolet light, and ultimately the effectiveness and service life of the coating.

The calculation of the mass of corrugated board is carried out to solve the following construction issues:

- Planned strength of the future structure. Its ability to withstand snow and wind loads, contact with solid objects, and possible actions of vandals without breakage and deformation.

- Parameters of the rafter system, frame, foundation. Their bearing capacity must correspond to the weight of the sheets, including spacers and fasteners. Depending on the technical characteristics of the sheets, the type and pitch of the lathing used for fastening self-tapping screws, the possibility and necessity of insulation and waterproofing are calculated.

- The order of transportation and storage of panels. Methods for lifting them to the roof. The need to attract assistants, rigging and lifting devices, types and types of stops for installers.

The best performance characteristics are possessed by sheets with average weight indicators. Such products optimally combine an affordable price, ease of installation and sufficient strength.

What determines the weight of the corrugated board

The weight of the profiled sheet is indicated in grams per square meter of the finished product area. This criterion is variable, inherent in each model and products from different manufacturers.

The following parameters affect the specific gravity of the material:

- Plate thickness. Each country has its own technical standards, in Russia GOST 24045-94 is in force, according to which it is set within 0.45-1.1 mm. The thicker, the stronger and more reliable the flooring. However, here you need to adhere to the principle of reasonable sufficiency, choosing the option that is optimal for a specific task.

- Metal consumption. In the manufacture of profiled sheet, various grades of steel are used, which has a significant effect on the weight of the final product. It is recommended to choose a product made from premium metal grades.

- The shape and height of the ridge. The larger they are, the higher the strength and weight of the finished board. A large wave takes up almost half of the workpiece area. Additional material consumption affects the weight of the workpiece passed through the press. More practical is a trapezoidal section with straight lines. The metal consumption for it is higher, but there are no problems with fastening characteristic of rounded contours.

- The density of the paintwork. The minimum layer is a few microns, high-quality models are covered with a fairly thick layer of paint.This makes the material beautiful and resistant to corrosion, and gives it sound insulation properties, which is important when building close to roads.

- Type of anti-corrosion coating. The more it is, the better the coating resists mechanical stress, moisture and solar radiation. Polyethylene is softer, weighs less, and its mechanical strength is lower. The well-proven pural is harder and heavier.

The mass of the profiled sheet is a derivative of many quantities. The total value for products from trusted manufacturers can differ significantly from a fake or substandard product.

The weight of the most popular grades of material

There are such types of corrugated board:

- Wall. It is designated by the letter "C". The sheets are characterized by increased strength and reliability with an almost complete lack of flexibility. These properties determine the scope of its application. Wall panels are suitable for finishing residential and commercial buildings as roofing, strong fences, wall cladding. In the production process, the best grades of steel, paint and protective coating are used. The profile is rectangular and trapezoidal, which has a positive effect on the bearing capacity. The thickness of the sheets is 0.5-0.7 mm, the height of the ridge is up to 57 mm. Accordingly, the weight of 1 m2 of corrugated board is in the range of 4.5-6.8 kg.

- Carrier. It is designated by the letter "H". The strongest material, which is more often used for structural purposes, since it has the maximum bearing capacity among its analogues. Hangars, sheds, warehouses, pavilions and similar structures are made of sheets. Metal can only be opened with powerful special tools. The thickness of blanks for stamping varies within 0.7-1 mm, with a profile height of 60-114 mm. The weight of a square of finished panels is 8.7-16.5 kg. The advantages of this lineup also lie in their durability. With such a thickness and provided that the protective coating is damaged, they will last at least 25 years.

- Universal. It is designated by the marking "C" and "HC" depending on the thickness, alloy composition and configuration. Has a wide range of applications in private and commercial construction. It does not possess high load-bearing properties, but it is well suited for the construction of roofs with steep slopes, light fences, decorative cladding of residential buildings and outbuildings. The material is lightweight, but it can withstand even strong snow and wind loads. Profiles are wavy, rectangular and trapezoidal. Thickness 0.5-0.8 mm, weight per square meter 4.7-10.5 kg.

When planning a construction, it is not necessary to be limited to one type of profiled sheet. To create reinforced concrete floors and a solid fence under the barbed wire, it is better to start up supporting sheets. The wall one is suitable for adjacent buildings, and the universal one for roofing. Meter lines are used to create a blank bottom of the fence between adjacent sections.

How to calculate the weight of corrugated board

You can use the following methods for calculating the mass of flooring from a profiled sheet:

- Electronic calculator. Similar services are available on the websites of construction companies and large stores. The program works with a high degree of accuracy and gives a result with a maximum error of 10% when construction is carried out with deviations from the specified conditions. The calculator windows enter data on slopes (type of roof, quantity, length, width, steepness), corrugated board (brand, type, width, length) and the amount of overlap along the vertical and horizontal lines.The resulting number is rounded up, 2-3 units are added to it as a reserve to cover damage during transportation and installation. Knowing the weight of the sheet of corrugated board, it remains to perform the multiplication action and get the result.

- Schematically. A more accurate but time-consuming option that allows you to get an absolutely accurate result. Diagrams of each slope are drawn up, on which the positions of the sheets are applied, taking into account adjustments in height and width. If there are straight and curved cuts, their parameters are adjusted to fit right-angled triangles, the area of which is easily calculated. The resulting values are then converted to weight. As an example: the weight of a C10 profiled sheet with a thickness of 0.7 mm with a working width of 100 cm and a length of 200 cm is 13 kg. The roof covering requires 23.5 m² of material, that is, 12 sheets. The total weight of the panels is 163 kg. Then you need to add to this a lot of additional details. These include ridge, corner, end profiles and valleys. Their total length is 30 m and a width of 60 cm, only 18-20 m² or 130 kg. And lastly, for each square you need 10 self-tapping screws, each of which weighs about 50 g. 235x0.05 = 12 kg. As a result, the assembled mass of the roof covering will be 163 + 130 + 12 = 305 kg.

If the project is drawn up for a private house, components should be included in the calculations, without which its normal functioning is impossible. These are ventilation hoods, pipe seals and snow protectors. Their total weight can be up to 200 kg, depending on the type and frequency of installation.