The phrase "gate valve" is familiar to professionals who install air duct, ventilation and chimney systems with their own hands. This definition sounds florid, but it corresponds to the meaning of the common word "damper", which is known in the most remote Russian village. No stove or fireplace is made without a damper, it does not allow warm air to quickly go outside.

Types of dampers

A gate is a simple valve that blocks / regulates the flow of air or other liquid / bulk materials. Gate valves of this type can also be used in pipelines that pump waste water and other aggressive media.

The industry manufactures two types of such dampers: rotary gate and horizontal. The first type of gate has another name: throttle valve. This type of locking mechanism is less reliable than horizontal. Therefore, it is used only in situations where it is technically impossible to install a horizontal locking mechanism with your own hands.

The horizontal damper is usually used in steel and brick chimneys. In order for it to completely cover the furnace channel, the locking plate in this mechanism is perforated or has a cut - such are the requirements of fire safety.

Gate valve for ventilation, air duct, chimney

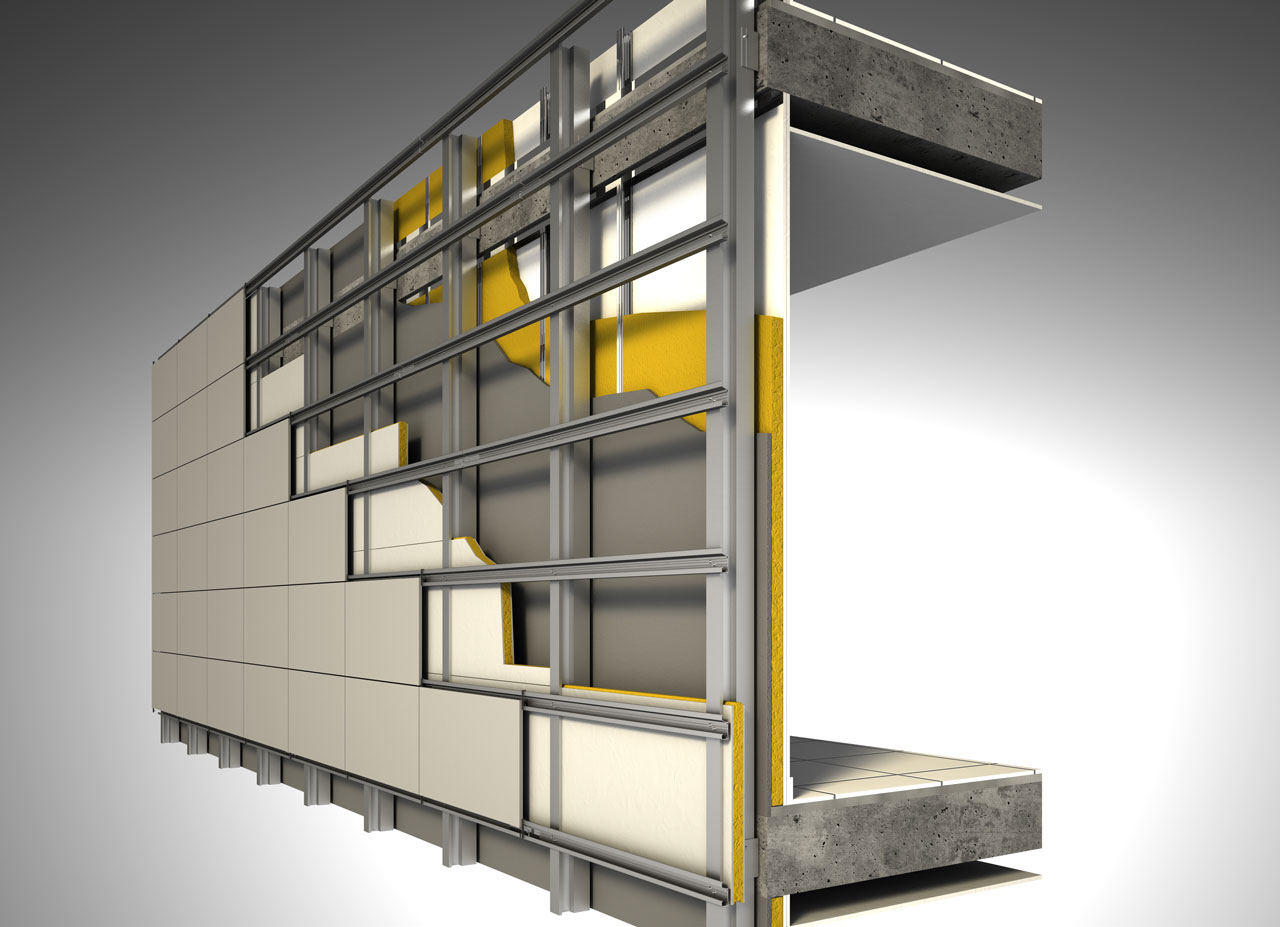

The locking mechanism, depending on the size of the gate, can operate on two types of guides:

- duct size up to 25 cm - in a slotted pocket;

- if the air duct is larger, the valve is fixed with a pair of corners. This design of the locking mechanism is easier to open / close and clean from dirt.

Gate installation - angle selection

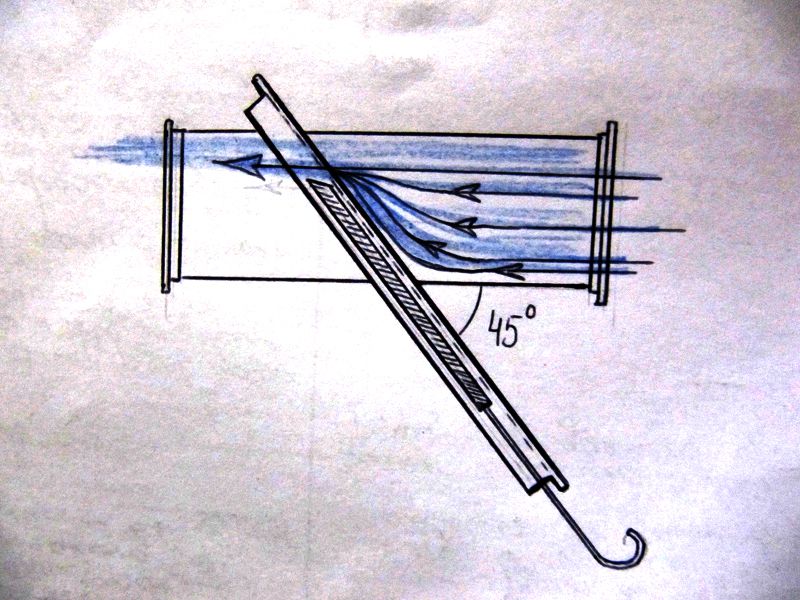

The standard damper blocks the air flow at a 90 degree angle. This design has a significant drawback: even a weak air flow contributes to the formation of noise, which negatively affects others.

The designers found a way out: the locking mechanism blocks the air flow at an angle of 45 degrees. With this design, the swirl is much less. That is, there is no factor causing unwanted noise.

Horizontal rotary gate: design features

The design of the locking mechanism is influenced by:

- shape and diameter of the outlet, air duct system;

- temperature of the medium / material transported through the system;

- conditions of passage and other factors.

The basis of the gate valve is a metal sheet (chrome-plated, high-alloy, stainless steel) of the required thickness. The locking mechanism moves in a slotted pocket or along metal corners.

Gate valves differ in the type of drive of the locking mechanism: manual, electric, hydraulic, pneumatic.

DIY installation of a gate valve

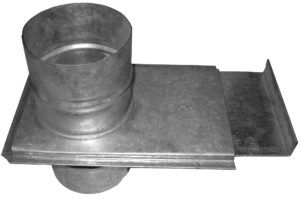

The most common place where a gate valve is installed is at the fan outlet. If the fan is installed with an adjustable damper, this design is called a starting damper. In this design, the valve acts as a protective plug that prevents the fan motor from overheating.

It is necessary to start the fan motor with a closed gate, since with an open locking mechanism, an additional load will act on the electric motor. Such additional impact can lead to damage to electrical equipment.

During the installation of a gate device with your own hands, you need to take into account the fact that the presence of a direct chimney will complicate the maintenance of the exhaust system.

Some features of installing a gate for a chimney with your own hands

The chimney damper is installed in two ways:

- pipe to pipe - the shut-off device is mounted in the chimney, without any fasteners;

- the locking device is installed directly in the stove or in the outlet. That is, the valve is part of the structure. In this version, the locking mechanism is mounted at a height of no more than one meter. This makes it possible to easily set the mechanism in motion.

Use gate valves in the oven so as not to be poisoned by carbon monoxide.

The knowledge of when it is possible to close the damper in the stove so that the heat does not go out of it in vain was passed on from parents to children. The rule is simple: while tongues of flame are "moving" in the oven, it is impossible to completely close the damper so that people cannot get poisoned by carbon monoxide. As soon as the flame in the furnace disappeared, the damper can be safely closed without fear of poisoning.

You can do everything with your own hands that does not require a special tool or materials. Installation of a gate valve does not require either the first or the second, but only basic knowledge and care during operation.