The air handling unit with recuperation is the most economical solution to date. But the purchase of equipment requires additional costs. We will tell you how to make your own ventilation with heat recovery, spending very little money and time.

Heat recovery efficiency

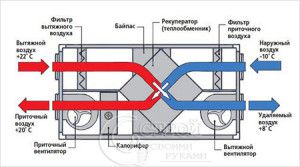

Recuperation is heat exchange, and in translation from Latin “return of used”. In the supply and exhaust ventilation, the recuperator takes heat from the air leaving the room and gives it to the cold supply air. In winter, the difference between the temperature of the exhaust air and the air supplied to the house can reach 40 degrees. Usually, heating occurs due to heating devices, that is, the wallet of the residents of the house.

In hot weather, the recuperator is also useful, because the hot fresh outside air makes the air conditioners work more intensively. A heat recuperator for ventilation, correctly assembled with your own hands, will reduce the difference between the temperature of the incoming and outgoing air flows by 4 - 5 times.

Benefits of heat recovery ventilation:

- homemade heat recuperator in ventilation systems has an efficiency of at least 65%;

- ventilation of an apartment with recuperation allows you to save at least 30% of your electricity bills;

- a very simple design does not fail, since there are no moving parts in it;

- the heat exchanger in the heat recuperator of the ventilation system is easy to maintain and maintain;

- the device works without using electricity;

- heat recovery provides not only ventilation of the apartment, but in some cases also regulates humidity.

The savings from heat exchange are the higher, the greater the difference between the temperature in the house and outside.

Making a plate ventilation recuperator with your own hands

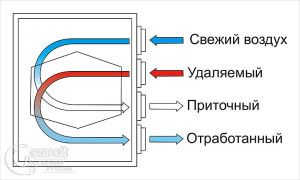

In a lamellar recuperator for ventilation, the flows of incoming and outgoing air are separated by plates of heat-conducting material.

Thus, the streams do not mix, but heat is released.

The ventilation system with a plate-type recuperator is simple and very common. Do-it-yourself supply and exhaust ventilation with recuperation can be done by a person with minimal mechanic skills.

Work progress:

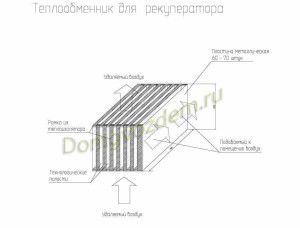

The basis of a recuperator for a ventilation system is a heat exchanger. Heat exchanger plates are cut from thin sheet metal (galvanized) or PCB. It is necessary to cut 20x30 cm plates. They must be very even and neatly cut. Metal is best cut with a jigsaw, avoiding the use of metal scissors;

- A distance frame made of technical cork, PCB or wood up to 3 mm thick is made between the plates. The frames are glued to the plates with polyurethane glue. So that the resistance to air flow is not strong, the gaps between the plates should be about 4 mm .;

- The structure is glued with a neutral sealant that does not cause corrosion;

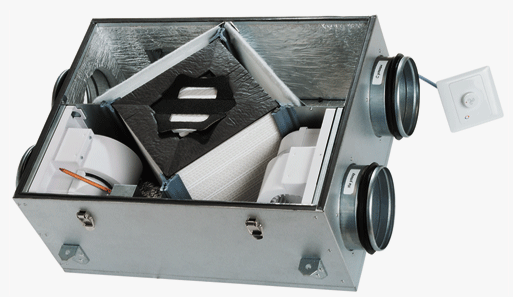

- The casing for the recuperator in ventilation is made of sheet metal or plastic, metal or MDF. From the inside, the box is lined with mineral wool or other insulation with a layer of 5 cm;

- On opposite sides of the box, two holes are made, to which plastic flanges are attached, equal in diameter to the air pipes. All cracks are carefully sealed with silicone;

- To drain condensate from the heat recovery ventilation unit, it is necessary to equip a drain pipe.

Tips for manufacturing a plate recuperator for ventilation

recuperator operation diagram To reduce the noise from ventilation with a heat recuperator, a box is constructed from a moisture-resistant material (drywall), the walls of which are lined with insulating material;

- When designing ventilation with heat recovery with your own hands, it is necessary to take into account the speed of air movement, which can be increased by no more than 1 m / s;

- The total area of the heat exchanger plates should be 3.5 - 4 square meters. meter to obtain a recuperator efficiency of 60%;

- It must be borne in mind that in frosts from -10 degrees and below, the plate heat exchanger can be covered with ice. It is thawed from time to time, and a differential pressure sensor is installed in the warm half. In the event of freezing of the ventilation system with recuperation, the sensor will register an increase in the pressure drop, the air will be supplied through the bypass, and the heater will be thawed due to the heat of the exhaust air.

Making a tubular recuperator with your own hands

The ventilation unit with the recuperator of the tubular coaxial type is easier to assemble than the plate type. But it is more massive and the longer the device, the more efficiently it works.

Materials for the manufacture of a tubular recuperator for ventilation:

- PVC sewer pipe 200 cm long and 16 cm in diameter;

- air aluminum corrugated pipe 400 cm long and 10 cm in diameter;

- splitter adapters with a diameter of 10 cm.

Work progress:

The corrugation is stretched and inserted in a spiral into a plastic pipe. Each of the corrugation ends is attached to one of the splitter rings and treated with a sealant.

On the one hand, the fan drives warm air from the room into the resulting device, while cold air from the street penetrates between the walls of the plastic pipe and corrugation. Through thin aluminum walls, heat is transferred from the exhaust air to the fresh air.

The advantage of this system is that supply and exhaust ventilation with heat recovery compared to plate ventilation in a smaller amount of condensate. And even its presence does not interfere with the operation of the recuperator. At the same time, a tubular recuperator is not suitable for installation in an apartment due to its size, but for a private house, the design is very good.

Another type of supply and exhaust ventilation system with heat recovery is presented in the video:

It is possible that the efficiency of the ventilation units with heat recovery given by us is lower than that of branded devices of factory production. But by assembling any of them yourself, you significantly save money, and subsequently you will get an effective installation and comfort in the room. Self-made ventilation systems with recuperation are very often equipped in garages and in country cottages.