The ventilation system is a complex combination of various devices and elements that provide fresh air and exhaust used air. It is transported through bends, channels, transitions and gratings, which will be discussed below.

Round plastic ventilation ducts

Round plastic ventilation ducts are widely used in natural and forced ventilation systems for residential or industrial premises.

Cylindrical plastic air ducts have several advantages:

- smooth walls reduce resistance to air flow;

- plastic air ducts do not need to be soundproofed;

- not destroyed by moisture and chemicals;

- inexpensive;

- low weight and a large number of round transitions for ventilation makes installation quick.

Plastic round ventilation ducts are installed in rooms that require enhanced air exchange, since the round cross section creates almost no resistance.

Round plastic ventilation ducts are well suited for chemical and electroplating industries, as well as buildings with high humidity.

A pipe with a diameter of 10 cm per hour will pass 300 cubic meters of air. If the diameter of the duct is less than the calculated one, it will hum more.

Disadvantages of ventilation from plastic round ducts:

- harder to mount than rectangular;

- low fire resistance;

- If the plastic circular vent is not treated with an antistatic agent, it will attract dust and debris.

They are used in aggressive environments where metal pipes will quickly become unusable. Plastic round ventilation is used in the range of -40 to +95 degrees.

Plastic air ducts for round ventilation have been in operation for more than 20 years without losing their properties.

Plastic does not emit harmful substances into the air, and round ventilation pipes allow you to create a sealed structure without suction and pressure loss. Round plastic ducts for ventilation can be adjusted to size right on the spot, which greatly facilitates their installation.

Round flexible air ducts

Corrugated round ventilation pipes are made of PVC coated wire, aluminum foil. Flexible plastic pipes with circular cross-section for ventilation do not belong to corrugated pipes.

Flexible round plastic ventilation can be:

- with thermal insulation of increased strength or standard;

- without insulation (standard or high strength);

- soundproofed (equipped with an internal air duct).

Pros of flexible ducts:

- ease of installation, dismantling;

- ease of maintenance and repair of the ventilation system;

- ease of transportation and storage;

- light weight;

- ease of replacing the route if necessary;

- low price.

The round plastic ventilation duct can be bent several times without tearing or cracking. It can withstand up to 60 degrees Celsius. The corrugated pipe can be operated up to +95 degrees.

Flexible air ducts are not installed on long routes, since the sagging of the pipe is allowed no more than 5 cm.

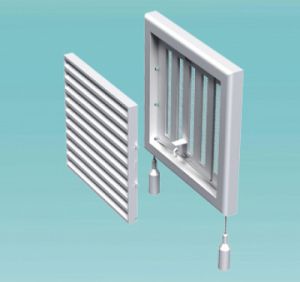

Round ventilation grilles

The round plastic ventilation grill is a must-have component of any system, which performs a number of functions:

- provides air inflow and exhaust from the room;

- prevents dust, dirt and insects from entering the room from ventilation ducts;

- gives the ventilation outlet a neat look.

In some cases, air circulation depends on the state of the round ventilation grill. Ventilation grilles of any shape, round or square, are easy to install. And their operation does not cause difficulties: care consists in periodic cleaning of dust and dirt.

The direction of the air stream depends on the design of the round ventilation grill: in one direction, two, three or four at once. Passing through the grate, a fan-type air stream is formed, flat, compact or otherwise.

According to the installation method, all round plastic ventilation grilles are:

- internal;

- outdoor;

- overflow.

All square or round ventilation grilles, according to the nature of their use, are divided into:

- exhaust;

- supply air;

- round external ventilation grilles.

Outside round ventilation grilles installed outside the building. They are necessary to protect ventilation ducts from leaves, mice and rats, birds. Most often they are made from special aluminum alloys that do not oxidize and are resistant to ultraviolet radiation. All round external ventilation grilles are covered with blinds at an optimal angle, which are warmed up in winter to prevent icing.

Internal round ventilation grilles 100 mm and other diameters are designed for indoor installation, hidden from the effects of destructive factors. Therefore, they are most often made of plastic. Round ventilation grilles 250, 100, 80 mm are equipped with manual blinds, the middle part can be removed from them for cleaning.

Transfer or door round ventilation grilles they are installed not only on doors, but also into walls. They serve for the unimpeded movement of air flow from one room to another. Louvers of a special shape are installed on round door ventilation grilles, which provide sound insulation.

Round ventilation grilles are adjustable, non-adjustable, inertial.

Although round ventilation grilles look better, rectangular or square ones are more often installed. The adjustable round ventilation grilles are equipped with movable louvers that change the direction of the air flow and the cross section.

Non-adjustable round ventilation grilles are produced without such louvers, that is, it is impossible to change the air flow manually.

In inertial grilles, the blinds open and close automatically depending on the movement of air.

Grilles are made of plastic, wood, steel, aluminum.

Metal, as a rule, are installed outside buildings, as they are more durable. Plastic round ventilation grill 100 mm can be supplemented with decorative elements. The advantage of plastic round ventilation grilles is their low weight, which can be installed on any surface. The choice of plastic ventilation grilles of round, square or rectangular shape is very large. Their price is much less than metal or wood. You can choose not only the form and function, but also the color that fits into the interior of the office, bathroom, kitchen.

Many manufacturers custom-made round ventilation grilles of any size and color.

Wooden door grilles for ventilation, as a rule, are not round, but rectangular. Other types of ventilation grilles for indoor use are also made of wood. They are decorated with carvings, they are environmentally friendly and look very dignified. These round door ventilation grilles are quite expensive and require special care.

Round ventilation hood

Rectangular and round ventilation hoods protect ventilation shafts from precipitation. The type of umbrella is selected depending on the shape of the channel section: for round ventilation ducts, round umbrellas, for rectangular ones, respectively. The second most important criterion: matching the diameter of the ventilation pipe and the diameter of the round umbrella. Round ventilation hoods are suitable for natural draft and forced draft systems.

In the manufacture of umbrellas, the following types of connections are used:

- bandage;

- nipple;

- flanged.

Round ventilation hoods are made of rolled or sheet galvanized or stainless steel.

In addition to the functional load, the ventilation umbrella is also aesthetic: the exit of the round ventilation channel looks complete only after the umbrella is installed.

Round ventilation ducts

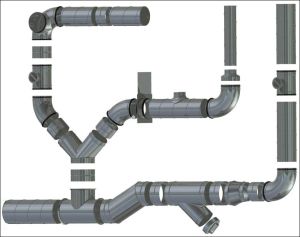

Elbows are required to rotate circular ventilation ducts at angles of 30, 90, 60, 15 and 45 degrees. Round ventilation outlets are made of rolled galvanized or stainless steel with a thickness of 0.55 - 1 mm.

The standard elbow is designed according to the scheme diameter = turning radius.

But on request, round ventilation outlets are produced with any turning radius from 150 mm and any neck length.

Elbows are assembled from separate segments, fastened to each other with a lock connection. Their size and number are determined by the angle of rotation. Elbows with the smallest diameters are made by stamping.

As a rule, the diameter of the circular ventilation duct is slightly smaller than the diameter of the circular ventilation duct. The branch is simply inserted into the duct, which saves on fasteners and fittings.

The branches are connected with nipples or flanges.

Shaped products of small diameters can be purchased immediately, large and non-standard ones should be ordered. When ordering, specify the retraction angle, diameter and turning radius (if not standard).

Round transitions for ventilation

You cannot do without transitions where it is necessary to connect air ducts of different diameters and cross-sectional shapes. For example, when repairing a ventilation system with a rectangular section of air ducts, you need to install a section of a duct with a circular section. This happens when rooms for various purposes are served by one ventilation system. The types of air ducts for them can also be selected differently. And to connect them into one system, round ventilation passages and branches are used.

The transitions are performed according to certain rules, otherwise the air will not be evenly distributed over the channels, especially for transitions from a round to a rectangular section.

Round transitions for ventilation can be:

- central;

- one-sided;

- asymmetrical.

Transitions are made of a strip of galvanized or stainless steel with a thickness of 0.55 - 0.7 - 1 mm with a flange or nipple connection.

Video on how round ventilation passages are made: