Practical and inexpensive plastic ventilation systems are gradually taking over the market from their metal counterparts. Professionals and DIYers like to work with plastic ventilation elements: air ducts, outlets, hatches and grilles. Plastic ventilation has a wide field of application, there are many advantages, but there are also disadvantages.

When is this an inappropriate choice? Is it possible to independently calculate the dimensions of plastic ventilation, mount the system?

Types of plastic for ventilation

Parts of plastic ventilation systems are made from three types of plastics:

- polyurethane;

- polyvinyl chloride or PVC;

- polypropylene.

The most widely used in various ventilation systems are rectangular plastic pipes made of PVC, they can be of light or medium type. PVC pipes are the cheapest and most reliable.

Polypropylene air ducts are good for everyone, but much more expensive than PVC. Since polypropylene is less strong, the walls of the parts are made thicker, which means that more powerful fasteners are required.

Polyurethane pipes are quite expensive and therefore less common. And the surface inside the pipes can have roughness, which reduces the aerodynamic properties of the products.

PVC ventilation properties:

- durability: service life - 50 years, products retain color, shape, physical properties;

- environmental Safety;

- chemical neutrality;

- tightness;

- easy to install and maintain;

- are lightweight;

- inexpensive.

The first and almost the only drawback of plastic ventilation systems: poor resistance to high temperatures and fire.

It is forbidden to install pipes for transporting vapors and air mixtures with temperatures above 80 degrees Celsius. It is this property that significantly limits the use of plastic products for ventilation systems in industrial enterprises.

The scope of application of plastic components for ventilation: any household, public and industrial premises that do not belong to I and II classes of fire hazard.

Do not install plastic ventilation on the following objects:

- production with the release of hot steam and open fire;

- saunas and baths;

- chimneys and chimneys;

- ventilation of solid fuel boilers.

Shapes and sizes of plastic ventilation elements

For the arrangement of ventilation systems, plastic air ducts of various types and sizes are produced:

- rectangular section;

- round section;

- corrugated.

Round air ducts are more economical and efficient, the inner walls allow air to pass through without turbulence and pressure reduction.

Rectangular plastic ventilation ducts reduce the air flow rate. This factor should certainly be taken into account when selecting the power of the equipment. But it is very convenient to form flat ventilation systems from plastic rectangular ducts that take up a minimum of space. That is why plastic rectangular ventilation is very popular among owners of country houses.

Flexible plastic air ducts for ventilation, they are mainly installed in short, curved sections. The corrugations create quite a lot of air resistance, therefore they are noisy, and also reduce the overall efficiency of the system.

Dimensions of plastic ventilation ducts:

- Round air ducts are manufactured with diameters of 55 - 150 mm;

- Rectangular plastic ventilation ducts: 6 x 12 cm, 6 x 20.4 cm;

- Flexible corrugated air ducts are manufactured with diameters from 10 to 50 cm. The length of one piece of pipe can be up to 20 meters.

Rigid plastic ventilation ducts with a diameter of over 22.5 cm are used exclusively in special projects. Numerous plastic components for ventilation make it possible to create systems of any configuration.

All types of plastic components:

- turns;

- corners;

- adapters;

- forks;

- holder connectors;

- couplings;

- bends;

- flanges;

- reducers;

- tees.

They are produced in standard sizes, corresponding to the cross-sections of round and rectangular ventilation ducts. When sizing plastic ventilation, it is necessary to take into account that the inner diameter of the couplings must match the outer diameter of the pipe.

Plastic ventilation hatches and grilles

The ventilation grill is the beginning and end of any air exchange system. Plastic ventilation grilles form the entrances to the pipes and diffuse the air, preventing it from moving in a single stream. Ventilation grilles are made of plastic, various metals and even wood.

Aluminum, wood and plastic ventilation grilles structurally can be of different types:

- inertial;

- adjustable;

- unregulated.

As a rule, plastic models are made unregulated.

Depending on the location, the lattices are called:

- overflow;

- internal;

- outdoor.

Transfer or door plastic ventilation grilles are placed at the bottom of the interior doors. They provide air movement between the rooms of the apartment. Plastic door ventilation grilles can be equipped with blinds that overlap, blocking the spread of light and sounds. Plastic ventilation grilles are made in various sizes from 30 x 15 cm to 60 x 25 cm.

Internal invoices plastic ventilation grilles are used in apartments and offices to decorate the entrance to the ventilation network. Some models of surface-mounted plastic ventilation grilles are equipped with rotary air guides. Plastic overhead ventilation grilles are usually produced in small sizes; there are design models that serve as an additional decoration.

Outdoor ventilation grilles are often made not of plastic, but of steel or stainless alloys, their size can be quite large, depending on the cross-section of the air ducts. Just like plastic ones, regardless of size, these ventilation grilles are always equipped with louvers. A check valve is often provided for in the project. In winter, the valve is closed and cold wind streams do not penetrate into the room.

Plastic ventilation hatches

Plastic ventilation hatches are also referred to as revision. They can be installed on a ceiling, in a wall or in a ventilation (plumbing) box. Through a plastic hatch, you can easily get to ventilation units, water meters or other important communications hidden by decorative trim.

The hatches are made of high quality white ABS plastic.

On sale there are standard sizes of plastic ventilation hatches from 10x10 to 40x60 cm.

The swing door opens to the right or to the left, depending on the installation method. To open it, you just need to press lightly on the surface.

The hatch is fixed with glue or mortar.

DIY plastic ventilation installation

When installing plastic ventilation with your own hands, pipes are connected to each other by soldering (tightly), on flanges or sockets. The second and third options make it easy to replace the damaged area. Air tightness and moisture resistance of plastic ventilation during DIY installation is achieved through the use of sealants and rubber gaskets.

The air ducts are attached to each other with silicone sealant.

Cutting round and rectangular plastic ventilation parts is easy with a hacksaw or a sharpened knife.

To mount plastic ventilation with your own hands, you will need tools:

- hacksaw;

- knife;

- pencil;

- side cutters.

And materials:

- clamps for fasteners;

- mastic;

- sealant.

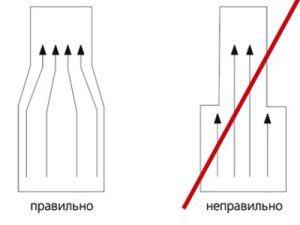

The flexible plastic ventilation duct is mounted as stretched as possible. Otherwise, the pressure on the highway will decrease significantly. With a socket connection, the branch pipe is inserted to a depth of 5 - 6 cm.

Sewer pipe ventilation

Plastic sewer pipes are made from the same types of plastic as ventilation pipes. At the same time, they are significantly cheaper, so some home craftsmen prefer to assemble ventilation from plastic sewer pipes, despite the fact that their diameter is 110 mm, which is not quite typical for air communications.

If the cross-section of the pipes meets the air exchange standards, they can be used.

The sewer pipes are not treated with antistatic agents, so dust particles will stick to the walls. They quickly form a thick layer.

And one more drawback - if you use them as supply air ducts, the smell of plastic may be present in the house for some time.

The diameter of all ducts must be the same, otherwise the draft in the system will be disrupted. Therefore, the corrugation with a diameter of 120 mm must not be fixed to a plastic sewer pipe in the ventilation system. At the junction, the air will be slowed down. If there is no other option, the transition should be gradual.

Plastic sewer pipes are somewhat heavier than ventilation pipes, so fasteners must be provided.

For sound and thermal insulation, after installation, blow the open sections of the pipes with polyurethane foam.

This is an easy and affordable way to forget about condensation and unpleasant noise for a long time.

Before installing plastic ventilation with your own hands, consult a professional. He will help you select the best materials and plan the system correctly.

Video on how to use plastic sewer pipes when arranging cellar ventilation: