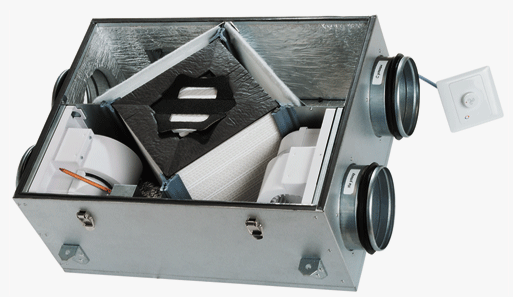

Galvanized ventilation pipes are widely used as air ducts in industrial and domestic systems. Through them, fresh air is supplied to the premises, and the exhaust air is removed. Galvanized air ducts are rigid and have high aerodynamic properties. They are easy to transport and install, and are not subject to corrosion. The average service life of galvanized ventilation pipes is 10 years.

Galvanized pipes can form the basis of ventilation systems in residential buildings, offices, public buildings, restaurants and shops, industrial enterprises. They are also suitable for central and rooftop climate systems.

This type of air duct is optimal if it is not planned to pass very hot, humid or air filled with aggressive vapors through the system.

Types and classes of tightness of a galvanized ventilation pipe

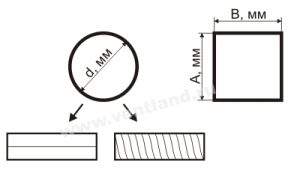

Sectional shape. The galvanized ventilation pipe differs in cross-sectional shape and manufacturing principle:

- longitudinal seam round;

- spiral wound round;

- rectangular.

Nipples are used to connect longitudinal and spiral seam pipes. Pipes of rectangular cross-section are made with flangeless or flanged connections.

Properties of galvanized steel air ducts:

- light weight;

- low price;

- you can create systems of any configuration;

- ease of installation and service;

- durability.

Galvanized pipes are used to move air flows with humidity up to 60% and temperatures up to 80 degrees Celsius.

A layer of zinc is applied to the steel sheet by hot method, creating a strong and highly resistant to aggressive media zinc film. It can even withstand contact with aldehyde resins and acid vapors.

For the installation of ventilation systems in accordance with SNiP 2.04.05 - 91, galvanized ventilation pipes of classes P (dense) or H (normal) are used. Dense galvanized ventilation pipes are characterized by increased tightness. The permissible values of air leakage are indicated in SNiP.

Dense galvanized pipes (P) are used in ventilation or heating systems with a pressure of 1.4 kPa, in rooms of fire and explosion hazard categories A and B, regardless of the pressure in the system.

Normal galvanized pipes (H) is established in any other cases. Small air suction from the system is allowed.

In the production of class P galvanized rectangular ventilation pipes, a special sealant is used, which is applied at the attachment point of the flange and air duct. Longitudinal seams are rolled in tunneling machines that ensure the highest possible tightness. Some manufacturers also treat longitudinal internal seams with a sealant at the request of the client.

Spiral coiled ventilation pipe

Spiral-wound galvanized steel ventilation pipes are machine-made from a galvanized strip 137 mm wide, twisted in a spiral. The edges of the strip are connected by the type of locking fastening. The seam is outside. Due to the special structure (stiffening ribs), this type of pipe is very strong and light. The tightness class of spiral-wound pipes is P, it is ensured by a silicone sealant with which the joints are processed.

Advantages of spiral-wound ventilation pipes:

- increased rigidity;

- easy installation;

- cheaper installation due to savings on fittings;

- the possibility of custom production of lengths up to 12 meters.

Pieces of pipes are attached to each other with nipples. If it is necessary to connect a pipe section to a fitting, the nipple is not needed. Flange mountings can also be used.

Passing through such an air duct, the flow receives additional turbulence and moves faster, producing less noise. The cost of spiral-wound pipes is lower than rectangular ones, so they are becoming more widespread in construction.

In the manufacture of galvanized pipes for ventilation, steel with a thickness depending on the diameter of the pipe is used:

- 0.55 mm - for a galvanized ventilation pipe 150 - 355 mm;

- 0.7 mm - for a pipe with a diameter of 400 - 800 mm;

- 1 mm - for pipes with a diameter of 900 - 1250 mm.

Usually, sections of galvanized pipe 200 of 3 or 6 meters are on sale, but for special types of ventilation, on request, the manufacturer can make an air duct of arbitrary length.

On request, spiral-wound galvanized pipes for ventilation are reinforced with additional stiffeners.

Straight seam round galvanized pipe for ventilation

Straight-seam galvanized air ducts are made of steel sheet, the edges of which are fastened with a nipple joint. Straight-seam pipes with flanges are also produced by special order. The steel sheet is cut automatically on the machine. If a non-standard size galvanized ventilation pipe 200 is required, the material is marked and cut on a manual guillotine. Next, the pattern is fed to the rollers with an electric drive, here it is wrapped in a tube of the required diameter, rolled and sent to the folding mill. The folds are upset along the entire length of the longitudinal edge of the pipe. Watch the video for the entire manufacturing process.

Such air ducts are used in ventilation systems consisting of ventilation ducts of short length, as a rule, in private construction.

Standard lengths of a longitudinal galvanized ventilation pipe are 1.25 m, but not more than 2.5 m. The lengths are fastened between each other with fittings. For tightness, the joints are treated with a sealant or sealed with rubber seals.

Advantages of longitudinal seam galvanized pipes for ventilation:

- relatively inexpensive (compared to rectangular);

- have the best aerodynamic characteristics;

- quieter;

- provide the fastest movement of air flows;

- are lightweight;

- mounted easier than rectangular.

The wall thickness of longitudinal welded pipes depends on their diameter. So for a ventilation galvanized pipe 150 mm - 350 mm, steel sheets with a thickness of 0.55 mm are used. The galvanized 300 mm ventilation pipe is sometimes made of 0.7 mm thick steel according to the customer's request. For air ducts with a diameter of 800 mm and more, steel with a thickness of 1 mm is used.

Rectangular galvanized pipe

Ventilation pipes made of galvanized steel of rectangular cross-section are produced on automatic tunnel assembly machines from sheet metal with a thickness of 0.55 - 1.0 mm. The larger the cross-sectional diameter, the thicker the material is selected. The minimum diameter of the duct is 10 x 10 cm, the maximum is not limited.

The production of galvanized rectangular pipes for ventilation is carried out in several stages:

- The sheet steel is fed to an automatic line for bending and forming stiffeners. Pipes with a non-rolled longitudinal lock come out of the line;

- A longitudinal lock is clamped on the longitudinal assembly apparatus. In one step, a fold is created, which is closed and rolled;

- A flange made of a bus-rail is put on and attached to the edge of the pipe. A corner is put on it. For tightness, it is treated with silicone.

The connection is provided by a flange made of a busbar, on the customer's request a flangeless connection or by means of a flange made of steel angle is possible.

Additional reinforcement of the ventilation rectangular galvanized pipe is necessary for cross-sectional sides from 400 to 1000 mm and is provided by stiffening ribs. The metal is bent in the transverse direction or in the form of crosses every 20 - 30 cm.

Rectangular galvanized pipes are suitable for any ventilation, since with a standard length of 1.25 m, you can order sections from 1 to 2.5 m.

Rectangular galvanized air ducts are manufactured in tightness classes H and P. Class P at the request of customers. Unlike class P, in class H products, a small air leak is allowed. High tightness of air ducts П is achieved by sealing the flange and longitudinal joint with a sealant. On customer request, the longitudinal seam is also coated from the inside of the pipe. However, a tightly rolled seam and lock provide a sufficient level of tightness even without special treatments.

Rectangular ventilation galvanized pipes of 300 mm and other diameters serve for a long time, reliably resist corrosion. But the operating rules imply periodic cleaning and checking the condition of the internal surfaces of the air ducts.

Shaped elements for galvanized pipes

Fittings are used to connect, turn and branch ventilation from 150 galvanized pipes.

Fittings include:

- tees;

- transitions;

- bends;

- umbrellas;

- corners;

- tires;

- crosses;

- sidebars.

They are made of rectangular or round cross-section, of various diameters for galvanized ventilation pipes 200 and any other dimensions. Sometimes, when installing complex ventilation systems, more shaped elements are used than pipes.

Which galvanized section to choose: rectangular or round?

A rectangular cross-section is more practical, since its cross-sectional area is larger than that of a round one. If very large boxes are installed, it is better to make them rectangular or square so that a worker can get inside for cleaning and service. Rectangular pipes are easier to clean.

But, if air filled with dust, sawdust or other impurities will pass through the ventilation system, a circular cross section is preferable to avoid the accumulation of debris in the ribs and corners of the pipes.

Rectangular air ducts are more durable than round ones.

Galvanized pipes for ventilation 300 of circular cross-section have sound-absorbing qualities, while rectangular ones, on the contrary, create more hum.