Ventilation systems must be equipped with filters. There are many varieties of them. They differ in the degree of purification, design, filter material, and principle of operation. Read about the variety of types of filters for ventilation and the subtleties of choice below.

Purpose of ventilation filters

In a supply ventilation system, a filter is necessary to purify atmospheric air before supplying it to the room. The air of modern cities contains dust, car exhaust, pollen and plant fluff. Therefore, ventilation grilles with filters are installed.

Filters for ventilation systems in production halls are even more important.

Unlike carbon filters for supply ventilation, a wide variety of fillers and designs are used in systems of plants and factories.

Many processes take place with the release of wood or metal dust, harmful or fetid gases. The release of impurities into the atmosphere would threaten an ecological catastrophe. Therefore, the exhaust ventilation of industrial enterprises is necessarily equipped with filters.

The principle of operation of ventilation filters

Filters of various types retain on their surface impurities from the air or absorb them.

On this basis, they can be divided into:

- porous;

- bulk (absorbing);

- fabric.

The most common representatives of the bulk category are charcoal filters for supply ventilation, they are effective and inexpensive. In addition to activated carbon, the smallest crumb of rubber, gravel, metal shavings, ceramic particles, coke can be used.

Materials for ventilation filters of a porous category can be finely perforated metal sheets, synthetic nets, non-woven materials.

Fabric filters can be classified as porous, they are made from natural fibers: cotton, wool.

Cleaning degrees of ventilation filters

There are three classes of ventilation filters according to the degree of cleaning:

- First class or absolute cleanup: particles less than 0.1 micron are retained. They are installed in electronic industries, in operating rooms and other sterile rooms, as well as for protection from radioactive dust and aerosol impurities;

- Second grade or fine cleaning: particles of 1 - 10 microns are captured. Their efficiency is 60-95%, they are installed in laboratories, clinics, pharmaceutical and food factories;

- Third grade or rough cleaning: particles larger than 10 microns are captured. Efficiency up to 90%. They are used as preliminary cleaning in very dusty rooms.

Often there is a need to install a number of ventilation filters of various classes, which purify the air in stages. Otherwise, with high dust content, the absolute filter quickly clogs and breaks down.

Replaceable cartridges with material for ventilation filters are provided for fine cleaning. Therefore, you can save on changing expensive consumables by pre-cleaning the air masses with ventilation filters of a lower class.

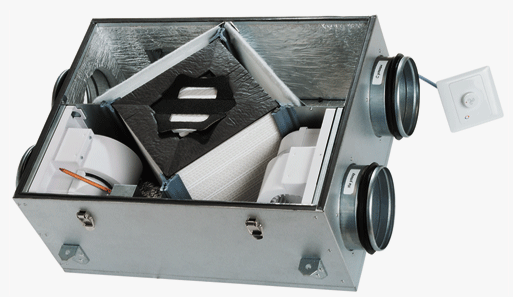

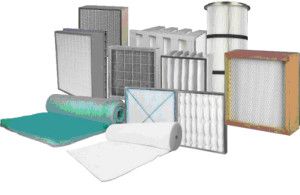

Types and designs of ventilation filters

The following types of filters are installed in the supply and exhaust ventilation systems:

- Rolled. The material for ventilation filters is most often polyester. The thicker the roll, the higher the filter cleaning class.

- Cellular. They are divided into two categories:

- Cassette ventilation filters. They are good for almost any ventilation system with rectangular ducts, therefore they are very widely used. Cassette ventilation filters are installed in industries, public buildings or residential buildings. The cassette ventilation filters provide high-quality coarse air purification;

- Pocket or bag filters. Coarse dust is very efficiently deposited, therefore it is often used as a primary stage for coarse cleaning. However, there are varieties with ventilation filter fabrics made of polyester, polypropylene or polyethylene fibers meeting the EU5-EU grades. Then pocket ventilation filters can be used as the only cleaning device. They can withstand up to 220 degrees Celsius and have an increased dust holding capacity (up to 300 g / sq. Cm).

- Duct... Duct carbon filters for ventilation are good because they can be built into any section of the air duct of an already installed system. In addition to the ability to trap dust and stench, the ducted carbon filter in the ventilation very noticeably drowns out sounds. Therefore, it is often installed after the fan as a silencer.

- Electrostatic or electrical. They clean the air of production workshops from the smallest particles of paint, oils, solid materials. Due to the influence of electrostatic fields, particles approach the surface and are held on it. They need to be cleaned in a timely manner, otherwise the efficiency of the filter is sharply reduced

- Panel filters for ventilation. Suitable for exhaust and supply systems, including those with re-use of air. Simple and effective enough. Panel filters for ventilation are made of a lattice metal base, framed by a mesh. A filter material is placed on it, the density of which is determined by the ventilation class. Panel filters for ventilation are produced with a profile width of 25 to 96 mm.

- Self-cleaning. They are widely used in industry, where it is impossible to stop the technological cycle for cleaning or changing the filter cloth in ventilation.

- Aerosol. Installed in hazardous industries (chemical and nuclear power). They trap dust, microorganisms and harmful chemical impurities, making the exhaust air perfectly clean.

- High temperature. It can be classified into a special category, although pocket filters for ventilation and any other designs can also be high-temperature. They are installed in saunas, baths, wood dryers. All elements of the body and the filter module are made of materials that can withstand temperatures up to +300 degrees, without deformation and without reducing efficiency.

- Bactericidal. Another category of highly specialized equipment is bactericidal filters for ventilation. They are installed on the inflow and recirculation of air masses. Before being supplied to the room, the air is totally purified from microbes, passing through the flow of ultraviolet radiation. Antibacterial filters for ventilation correspond to class H11. They trap life-threatening germs, viruses, bacteria, mold and fungal spores, and a special impregnation destroys them. The efficiency of antibacterial ventilation filters is over 95%. Bactericidal filters are always installed in the ventilation of laboratories, hospitals, clinics, cleanrooms.

- Fat traps. Grease filters for ventilation are made in the form of cassettes. They are a filter cloth fixed on a galvanized profile frame.Grease filters are installed in the ventilation of catering establishments directly into the hoods above the hobs.

As a filter fabric for ventilation, an expanded mesh of 5-7 layers with a mesh of 0.35 x 0.6 cm is used. The grease trap filter for ventilation can be washed by soaking it in hot water with detergent.

Filter materials in ventilation filters

The air purification class in the ventilation system depends on the characteristics of the filter material. Often, to obtain the best effect, several filter modules of different classes are combined with each other.

Separation of large suspensions is carried out using:

- metal mesh;

- nonwovens (padding polyester, felt);

- fabrics (cotton, flannel, flax, wool);

- paper;

- fiberglass.

In industry, the feature of fibrous filters is widely used to precipitate a chemical mist (fine suspension of paints, oils and other chemicals).

Metal mesh filters

Able to retain impurities with a particle size of at least 5 microns. That is, metal filters provide preliminary coarse cleaning. To make the mesh better "collect" dirt, its surface is sometimes covered with a layer of machine oil. Filters can be cleaned independently: the tape is passed through a container with oil, where the dirt is washed off.

Oil ventilation grill filters filter out more than 90% of impurities from the air and are capable of operating with dust content up to 25 mg / cubic meter.

Water filters

There are water filters that are installed in restaurants over open fire sources (for example, barbecues).

A water filter precipitates impurities and cools the exhaust air to 38 - 40 degrees before releasing it into the atmosphere.

Carbon filters

This material is more effective than others in capturing volatile and semi-volatile organic compounds. Therefore, ducted carbon ventilation filters are used to absorb relatively "heavy" molecules. This property is given to coal by microscopic pores, and the degree of air purification depends on their number. The more pores, the cleaner the air after the filter will come out.

Another important indicator of ducted carbon ventilation filters is the size of the granules. Large granules are less resistant to air flow than small ones.

Carbon filters are rarely used for pre-cleaning in supply ventilation systems, because they quickly become clogged and fail.

Sintepon filter mats

The basis for the production of filter mats is synthetic fiber, similar to padding polyester. Ventilation filters are equipped with mats of different thicknesses and with different degrees of purification: from EU2 to EU6.

Ventilation filters made of synthetic winterizer can withstand temperatures up to +80 degrees, are not affected by moisture.

Sintepon filters are designed for ventilation of premises with high dust load and for the first stage of filtration in painting and varnishing installations.

They are made in the form of ventilation grilles with a synthetic winterizer filter or in the form of a sleeve.

Fiberglass filter mats

All glass fiber filters have EU2 to EU4 cleaning classes. Depending on the variety, the following are used:

- in painting or varnishing installations;

- in furniture production;

- in the automotive industry.

Bactericidal ventilation filters are made from fiberglass. The antibacterial effect is achieved by additional coating of the surface of the fiberglass material with special compounds that repel dust and destroy microbes. Germicidal fiberglass ventilation filters are usually yellow in color.

They can withstand up to 200 degrees Celsius and are not affected by moisture.

The filter mats are sold in rolls. Fiberglass can be ordered according to the required size.The filter material for ventilation is framed with a metal corner and reinforced with a cloth.

A short video review of HEPA filters for fine air filtration: