Exhaust air is removed through the ventilation ducts and fresh air is supplied. The quality of the system depends on the correct calculation of the cross-sections of the ventilation ducts and proper installation. What and how to make a ventilation duct in a private house or apartment with a gas boiler and what is the throughput? Read on.

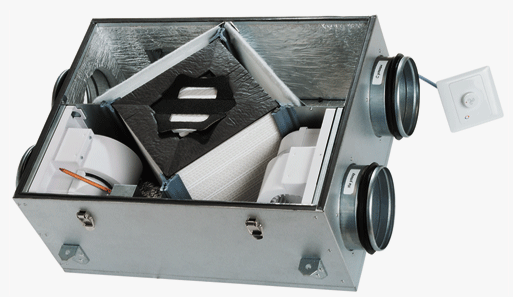

Selection of ventilation ducts

Duct density class, material and shape are selected depending on the characteristics of the object.

Ventilation systems of large enterprises are equipped with fully sealed dense air ducts (class P).

Ventilation ducts made of aluminum, PVC or galvanized steel of class H or "normal" allow slight suction. They are suitable for apartments, private houses and office buildings.

Sheet metal ventilation ducts

Galvanized and aluminum ventilation ducts are installed in industrial and domestic facilities. The best ventilation ducts for gas boilers are made of stainless steel. They have good aerodynamic properties and are good as outlet and supply ventilation ducts. Turns, bends, transitions to different sections and diameters are performed using shaped products. Additional advantages are durability and anti-static properties.

Metal air ducts are resistant to moisture and high temperatures, they work for 20-30 years. Aluminum and galvanized ventilation ducts withstand a temperature range of -35 to +280 degrees.

This is a versatile material suitable for everyone who does not know what to make a ventilation duct in a cottage out of. Heat resistance allows them to be used not only as ventilation ducts for gas boilers, but also for solid fuel ones.

Flat ventilation ducts are divided into sections up to 2.5 meters long. Ventilation ducts are fixed between themselves by naturally reliable flanges.

Round ventilation ducts made of aluminum are connected with nipples on self-tapping screws and are treated with a sealant.

PVC ventilation ducts

Round plastic ventilation ducts are good for domestic forced or natural ventilation with little air exchange. The smooth inner surface and the absence of corners in the channel create minimal resistance. The material does not corrode, therefore it is suitable for rooms with high humidity. Plastic ventilation ducts are very lightweight and easy to install. When deciding what to make a ventilation duct from, many craftsmen stop at PVC pipes due to the low price. But they deform at temperatures above +90 degrees and are highly flammable, therefore they are not suitable for removing hot air.

Plastic ventilation ducts of rectangular cross-section are easier to install than round ones, they take up less space. The resistance to air flow in them is higher, as well as the level of aerodynamic noise.

When installing plastic ventilation ducts, they are treated with an antistatic agent. Otherwise, the section of the ventilation duct narrows very quickly due to dust and debris adhered to the walls.

Flexible ventilation ducts

They are installed when the ventilation duct has many turns and folds, especially at a large angle.Convenient for small lengths. The corrugated structure creates maximum air resistance, and dirt and dust accumulate in the unevenness. Therefore, they are used less often at large facilities.

Flexible ventilation ducts do not install:

- in the risers of buildings above 2 floors;

- outside buildings;

- in case of possible contact with an aggressive medium or abrasive particles.

Flexible air ducts from metallized tape withstand up to +90 degrees, from laminated aluminum foil up to +140 degrees.

Flexible heat-insulating air ducts are widely used in residential premises. Outside, they are covered with a heat-insulating layer. Plus the installation of ventilation ducts of this type is simple installation.

The flexible air duct must not be in contact with heating pipes. Since it can deform from high temperatures.

The segments are connected to each other with a special adhesive tape. With proper installation, the ventilation duct will last more than 10 years.

Brick ventilation ducts

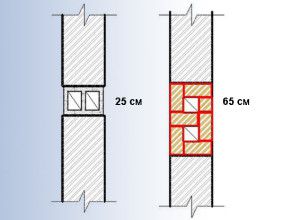

In private houses with stove heating, such ventilation ducts are very common. Brick ventilation ducts are installed in the inner walls of the building. A brick ventilation duct does not need a cross-section calculation, it is standard: 0.5: 0.5 bricks or 1: 0.5 bricks.

The best material for ventilation ducts is solid brick. The use of hollow is allowed, the cavities are filled with cement mortar or clay.

Silicate brick, which crumbles from temperature changes, is categorically not suitable.

Use the same mortar for brick ventilation ducts as for walls. Mix cement and sand in a ratio of 1: 3, dilute with water.

To obtain strong masonry, use clean and sifted sand, any impurities will reduce the quality of the mortar. The best cement grade is M-500. The thickness of the solution should be such that it does not pour out of the bowl inverted at 45 degrees.

A standard flat ventilation duct is laid out with a square cross section. Before starting work, make a markup using a template. Lay out buoy bricks at the level of 3 rows in a plumb line across the channel. They will cover the section of the ventilation duct from construction debris and set the direction for future masonry. The buoys make the duct stronger, but they complicate the cleaning of the natural ventilation duct somewhat. They need to be rearranged every 6 rows. You can use both multi-row and single-row suture dressing techniques. Stack bricks back to back.

One of the serious disadvantages of a brick duct is its high heat transfer.

To reduce it, create a bend in the duct to retain some heat. Lay the ventilation duct in a private house with a ladder, lay the solution in the niches, install bricks in 2 rows on top of the resulting slide on the edge.

For a gas boiler, it is necessary to equip a separate ventilation duct, it is strictly forbidden to use a common system for the exhaust!

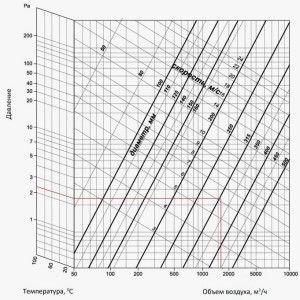

Calculation of the area of air ducts and fittings

The calculation of the area of the ducts depends on the air flow and its speed. When the speed exceeds the norm, the pressure in the system decreases. This means more electricity will be spent.

Competent calculation of the duct cross-section allows you to reduce the level of vibration and aerodynamic noise.

Professional designers use special programs such as "Duct Specifications" to calculate the cross-section of the ventilation duct. There are the most simplified versions of calculators available for free after registration. When calculating the cross-sectional area of the ventilation duct, you should take into account its shape: rectangular or round.

When choosing a larger cross-section, the air speed is reduced, noise and power consumption are reduced.

At the same time, the cost of air ducts increases significantly.

Manually, the cross-sectional area of the plastic duct is calculated using the formula:

P = 0.9 * s

here s - air flow rate.

Knowing the diameter of the round duct, you can choose a rectangular one instead, using our table. In the vertical column, the width of the duct, in the top row, the height. At the intersection of the columns, the diameter of the circular section. Dimensions are in centimeters.

| width height | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 |

| 25 | 21 | 24,5 | 27,5 | |||||

| 30 | 23 | 26,5 | 30 | 33 | ||||

| 35 | 24,5 | 28,5 | 32,5 | 35,5 | 38 | |||

| 40 | 26 | 30,5 | 34,5 | 37 | 41 | 44 | ||

| 45 | 27,5 | 32 | 36,5 | 40 | 43,5 | 46,5 | 49 | |

| 50 | 29 | 34 | 38 | 42,5 | 45,5 | 49 | 52 | 54,5 |

| 55 | 30 | 35 | 40 | 44 | 47,5 | 51,5 | 54,5 | 57,5 |

| 60 | 31 | 36,5 | 41,5 | 46 | 49,5 | 53,5 | 56,5 | 60 |

| 65 | 32 | 38 | 43 | 47,5 | 51,5 | 55,5 | 59 | 62,5 |

| 70 | 39 | 44,5 | 49 | 53,5 | 57,5 | 61 | 64,5 | |

| 75 | 40 | 45,5 | 50,5 | 55 | 59 | 63 | 66,5 | |

| 80 | 41,5 | 47 | 52 | 56,5 | 61 | 65 | 68,5 | |

| 85 | 48 | 53,5 | 58 | 62,5 | 67 | 71 | ||

| 90 | 49,5 | 55 | 60 | 64,5 | 68,5 | 72,5 | ||

| 95 | 50,5 | 56 | 61,5 | 66 | 70,5 | 74,5 | ||

| 100 | 52 | 57,5 | 62,5 | 67,5 | 72 | 76 | ||

| 120 | 62 | 68 | 73 | 78 | 83 | |||

| 140 | 72,5 | 78 | 83,5 | 88 | ||||

| 160 | 83 | 88,5 | 94 | |||||

| 180 | 87 | 93,5 | 99 |

Ventilation duct capacity

One and the same ventilation duct in combination with different equipment has a different flow capacity.

The throughput of ventilation ducts is influenced by:

- line length;

- number of branches and turns;

- the shape and diameter of the gratings;

- shape and material of the duct.

Each of these factors reduces the throughput of the ventilation duct.

Installation of vertical ventilation ducts

There are two main ways to install vertical ventilation ducts:

- building up from below;

- building up from above.

As a rule, air ducts are attached to the walls by building up from the bottom up. For the convenience of work, a hoist (winch) is installed at the ventilation assembly site. The section of the duct is lifted and hermetically fixed to the previous one. To prevent the air duct from falling, it is securely attached to the wall. When all the work is over and the quality of the fastening of the flat ventilation duct has been checked, the winch is removed.

The installation of the ventilation duct by the method of building-up from above is suitable when working with very heavy blocks. Separate sections of ventilation ducts are assembled by building up from below, after which they are mounted into a single structure from top to bottom.

The first block is lifted and temporarily fastened to the building structures. The second is fixed with permanent fasteners. During the lifting of the first block, a hoist rope is inserted into it, which pulls the second block from below. After that, the first is attached to the second with permanent supports.

DIY installation of ventilation ducts

An attic space or ceiling is the best place to install ventilation ducts in a private house.

Check the availability of all components before making ventilation ducts in a private house.

Installation of air ducts under the ceiling:

- Select the mounting height of the ventilation ducts for air intake and exhaust. Use clamps as fasteners;

- Insert the first section of the ventilation duct of a suitable section into the hole in the wall;

- Install the fastening clamp near the wall, put it on the air duct, and check the horizontal using a level;

- Attach the edge of the clamp to the ceiling;

- Install the clamps at a distance of 1.5 meters from each other. If the ventilation duct is made of stacked sections, place the clamps at the beginning and end of each section. The joints must be sealed.

Air ducts from the kitchen and bathroom are directed directly to the main ventilation duct, without connecting to other branches.

Install exhaust fans in horizontal air ducts, and cover the pipe at the outlet with a non-return valve.

The video tells in great detail about the installation of plastic air ducts: