Sheet metal ventilation elements are practical, durable and easy to install. Due to these and other properties, they are widely used in industrial ventilation systems. Private homeowners tend to prefer other materials.

Read more about the advantages, disadvantages and features of the operation of metal ventilation ducts, pipes and fittings below.

Types of metal ventilation elements

All the main and auxiliary components for the ventilation system are made of metal:

- air ducts;

- nipple;

- umbrellas;

- tires;

- stubs;

- bends;

- adapters;

- tees;

- sidebars,

- metal ventilation nets and grilles.

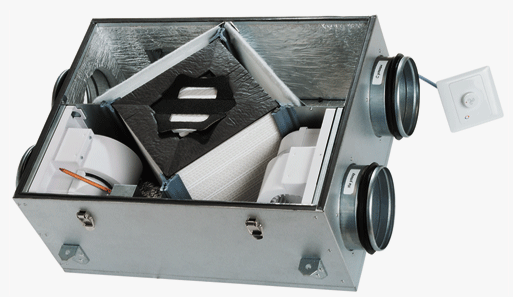

Metal air ducts

Air ducts make up the lines for transporting air streams. The air duct exits are covered with overhead metal ventilation grilles.

In cross-sectional shape, they can be:

- rectangular;

- round.

Manufacturing technology:

- longitudinal seam;

- spiral wound.

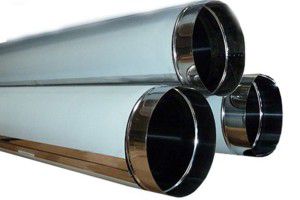

Straight seam metal ventilation ducts are made of thin steel sheet. The edges of the whole sheet are seamed (if the sheet thickness is not more than 1.4 mm) or by welding. A folded joint is not always tight enough and requires the use of additional material.

The welded joint is more laborious, but it does not have such disadvantages. Straight seam ducts are widely used to create short, straight sections.

They are produced in standard lengths and diameters of two tightness classes: "H" and "P". Class "H" or "Normal" indicates the likelihood of small air leaks. Pipes of class "P" are additionally sealed.

Spiral wound air ducts made of metal tape, which is curled into a tube using special equipment. A special rib gives additional rigidity to large-diameter pipes.

In residential premises, rectangular air ducts are often used, which are easier to fit into the interior. At the same time, such pipes create more air resistance. Therefore, in powerful industrial systems, preference is given to round air ducts with better aerodynamic characteristics.

Flexible and semi-rigid air ducts are often installed in small sections with many bends. Since the ribs of the corrugation create the greatest resistance to air movement.

Flexible metal air ducts

The technology of their production is completely different from the types described above, and the material is aluminum foil.

Flexible metal ventilation ducts can be:

- isolated;

- uninsulated.

They are a spiral frame made of rigid steel wire, on which several layers of laminated mylar film and aluminum foil are worn.Insulated flexible metal air ducts for ventilation are wrapped in a 3 cm thick layer of mineral wool, which is covered with an additional layer of foil on top.

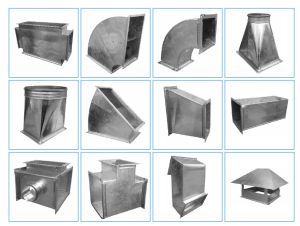

Metal fittings

Shaped metal products allow you to connect air ducts of various diameters and cross-sections, make turns and a variety of wiring. With the help of umbrellas or metal ventilation grills, the outlets of the ventilation pipes are made out. Metal ventilation grids protect air ducts from the penetration of small animals and debris.

Shaped parts are produced in a wide variety of types and shapes. Often, the main costs for installing ventilation are not for air ducts, but for fittings. They can be rectangular or circular, of various diameters and are selected for air ducts.

To assemble a standard air duct network, you will need the following minimum set of fittings:

- bends at 45 and 90 degrees;

- duck;

- nipple;

- tee;

- inset;

- stub.

Metal ventilation grilles are superimposed on the air duct outlet from the street side. External metal ventilation grilles can be equipped with a louver system. In winter or during periods of inactivity, the air duct is reliably covered from debris and dust. Such devices must be installed at large facilities.

In residential buildings, it is enough to cover the exit with a metal mesh for ventilation. Unpleasant odors and dust are removed from the toilet or kitchen through a metal ventilation grid.

Sometimes the outlet of ventilation pipes is placed in the floor (for example), in some industries or in saunas and covered with a metal ventilation grill for the floor. Most often, a metal grate is built into the floor to create an area of increased pressure in the working areas.

Metals for ventilation elements

Metal air ducts for ventilation are made of corrosion-resistant sheets:

- stainless steel;

- Cink Steel;

- aluminum.

Metal pipes for ventilation from stainless steel very durable and meet the highest sanitary and hygienic requirements:

- withstand up to +500 degrees Celsius;

- fungus and mold are not colonized in them;

- resistant to direct fire;

- resistant to moisture;

- resistant to aggressive environments.

Used metal steel boxes for ventilation of hospitals and clinics, schools, as well as in industries with high radiation levels, high temperatures and humidity.

Galvanized metal ventilation pipes are made of cold-rolled steel with sheet thickness from 0.5 to 1.25 mm, less often hot-rolled sheet is not thicker than 0.9 mm. In the second case, the steel is additionally treated with a primer.

- withstand up to +85 degrees Celsius;

- resistant to air humidity up to 60%;

- biologically stable;

- relatively inexpensive;

- easily assembled into a structure, leaking areas are replaced;

- are lightweight.

Due to these properties, galvanized metal ventilation pipes are often installed in warehouses and dry production.

Metal ventilation ducts are interconnected with flanges or nipples.

Aluminum air ducts are flexible or semi-rigid. They are made of aluminum foil of different thickness (from 0.08 to 0.12 mm). The main advantage of metal aluminum ventilation ducts is the ability to bend them at any angle:

- withstand temperatures up to +135 degrees (flexible) and up to +300 degrees (semi-rigid);

- resistant to aggressive environments and ultraviolet light (semi-rigid);

- can be installed in catering rooms, dryers and ironing rooms;

- do not need grounding.

Semi-rigid air ducts can be installed outdoors.

Metal ventilation ducts made of aluminum are practical, lightweight and inexpensive.They bend perfectly, they are attached to each other with a triple lock. Flexible metal ventilation duct can be squeezed and stretched several times. In a compressed state, flexible and semi-rigid air ducts are convenient to transport and store, their length is 50 cm. In an extended form, it reaches 3 meters.

Installation rules for ventilation elements

Before starting the installation of the ventilation system, it is necessary to survey the room and choose the best mounting method.

For fastening metal air ducts use:

- clamps;

- hairpins;

- corners;

- bolts and nuts.

Sometimes you have to resort to welding.

Installation of flexible metal pipes has its own rules:

- To reduce the pressure loss inside the pipe, they are mounted only in a stretched state;

- It is more convenient to cut off excess pieces at once;

- It is more expedient to use wide brackets that do not pinch the pipe;

- For passage through walls, one-piece adapters or metal sleeves are necessarily used.

Distribute the suspension points using the following rules:

- when cornering, the bending radius should be less than the diameter of the duct;

- sagging is allowed no more than 5 centimeters per linear meter;

- when installing the pipe vertically, there should be a distance of 1 - 1.8 meters between the fasteners.

Connection of air ducts and ventilation fittings to each other

To connect elements of a circular cross-section, use:

- Flange mount... To ensure a tight seam, the flanges are fastened with a flange. Flange holes must remain free;

- Bandage mount rarely used, mainly in hazardous industries. It provides complete sealing. First, the ends of the air ducts are flanged, then a bandage is put on. It is filled with a chemically neutral substance or conventional sealant. The technology is simple and inexpensive, but the manufacture of bandages is quite expensive. Therefore, it is not widely used;

- Coupling or nipple... Available with or without rubber seal. If there is no gum, a sealant treatment is required during installation. Particular attention should be paid to its composition and quality when placing the system outside a building or in aggressive environments;

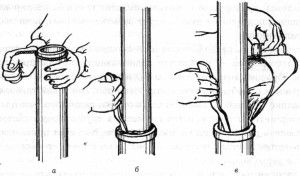

- Trumpet Is the simplest and most widely used connection. The smaller pipe is inserted into the larger pipe.

It is provided as follows:

- the air duct is made in the form of a cone;

- one end of the duct is slightly narrowed, the other is widened.

To connect rectangular elements, use:

- Flanges that are riveted or spot welded. The second option is simpler and more common, although it leads to a rapid burnout of the pipe at the welding points;

- Tires are the most common type of fastening in general exchange systems. The sides are connected to each other by corner inserts. On air ducts of large diameters (200 mm and more), a tightening element is certainly mounted.

When connecting rectangular ventilation pipes, it is imperative to seal the corners. Connections are laid with tapes from:

- monolithic rubber;

- foam rubber;

- polymer mastic cord.

Cons of metal ventilation elements

- More expensive than plastic;

- During manufacturing, roughness may appear on the inner surfaces, increasing air resistance;

- The relatively large weight of the structure, due to which it is necessary to use special fasteners;

- Corrosion susceptibility of "black" steel air ducts;

- Aerodynamic noise.

Ventilation made of metal from the outer grille to the air ducts has been a little squeezed in the market by polymer products that do not have the listed disadvantages. Nevertheless, today there is no better material for powerful air exchange systems than metal.

This is how longitudinal seam ducts are made on the most modern machines: