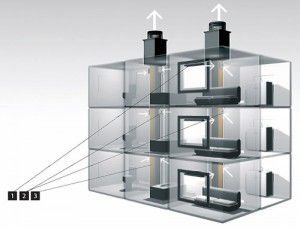

When mechanical ventilation system the movement of air masses is ensured by the operation of the fans. Such a ventilation system is used in cases where it is necessary to provide a certain outflow and a certain flow of air into the room. Mechanical supply ventilation ensures that a given volume of air is supplied to where it is required. The air is supplied with such temperature and humidity, which are regulated by sanitary or technological standards.

Mechanical exhaust ventilation removes gases, dust and exhaust air from the room, passes it through filters and throws it out. The mechanical ventilation system turns on or off when the process requires it. Therefore, in industry it is used more widely than the natural system.

Supply and exhaust mechanical ventilation

The mechanical supply system is designed to supply fresh air to the building. Mechanical exhaust ventilation extracts air from the building.

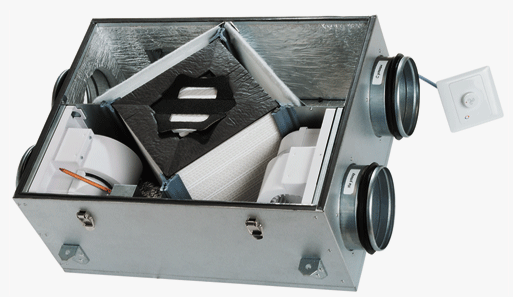

The scheme of mechanical supply ventilation is a combination of an intake device, filters, air ducts, fans and air blowing mechanisms (air curtains, showers, air-thermal curtains).

The exhaust ventilation scheme consists of an air intake mechanism, a fan, air ducts, filters of various degrees of purification, and an ejection mechanism.

Calculation of mechanical ventilation of the workshop

The calculation of mechanical ventilation is based on the coverage area of the equipment. The local system serves only a certain area of the workshop, while the general system processes all the air in the hall. The first option will be cheaper, the power of the equipment and the length of the air ducts in this case are less.

The first parameter determined when calculating mechanical ventilation is the air exchange rate. It gives an idea of the number of complete air changes in a room in one hour. So, if the area of the workshop is 100 sq. meters, and the ceiling height is 3 meters, the total air volume is 300 cubic meters, the double air exchange is 600 cubic meters per hour. The air exchange rate is determined by the work carried out in the room, the number of equipment and employees. For example, if a three-fold air exchange is quite enough for an office, then for a hot shop this indicator should be calculated based on the number of electric or gas stoves, the season, the dimming factor and many more indicators.