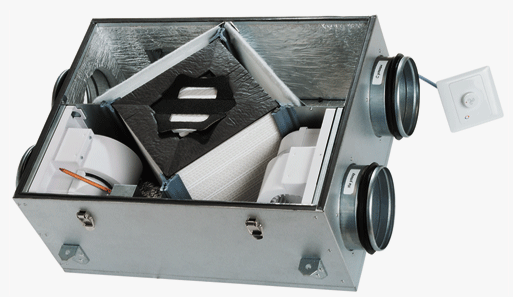

Ventilation control cabinets are designed for manual or automatic control of modern air exchange systems. They work with almost any type of ventilation equipment, are easy to install and operate.

Purpose of ventilation control cabinets

The cabinet for unattended ventilation control ensures the necessary temperature and humidity in the rooms that meet the requirements, and also increases the safety of the equipment. It allows you to set any indicators of the supply air and automatically maintain them for the required time.

The automatic ventilation panel is suitable for ventilation systems:

- with water heating;

- electric heating;

- heat recovery;

- recirculation;

- smoke control (retaining);

- supply, supply and exhaust and exhaust.

Parameters can be changed using remote controls or a computer network. In the event of an emergency, a signal is immediately sent to the control room.

Functions of automatic ventilation cabinet

Features of ventilation control cabinets:

- maintain the required constant power of the power grid;

- allow you to conveniently connect lines of different power voltages to different terminal blocks;

- control the intensity of rotation of the fans, start them smoothly and prevent phase imbalance;

- equalize power, preventing equipment overheating, overload and short circuits;

- control the voltage in the network autonomously, remotely or locally.

The supply and exhaust ventilation control cabinet operates in standby or summer modes. In summer mode, the air temperature is not controlled. When the supply air temperature is low, the cabinet automation switches the supply ventilation control to protection mode.

Standard functions

- Manual stop and start;

- compatible with temperature sensors for supply air, outdoor air, and return heat carrier;

- records the temperature of the fan motors contacts;

- regulates the function of the air valve actuator;

- prevents short circuits and overloads of the pump motor;

- controls the drive of the heat supply valve;

- prevents freezing of water heaters and freon coolers;

- prevents overheating of the electric heater;

- prolongs the stop of the supply air fan;

- gives signals about the need to clean the air filters;

- stops and de-energizes equipment in the event of a fire alarm;

- notifies with the help of light indication about the system operation;

- records accidents in a special log.

Advanced functions

remote control cabinet Prevents pressure drops when the fan belt breaks;

- Provides frequency conversion for fans;

- Regulates indoor air temperatures in a cascade manner;

- compatible with a thermosensor on the hood;

- notifies about an emergency by light indication;

- connection of remote control is possible;

- controls the operation of the air valve;

- provides connection of additional fans;

- two-phase control of the compressor-condenser unit;

- five-phase control by an electric heater;

- controls the mixing chamber;

- prevents freezing of the recuperator and rotary recuperator;

- controls air humidifiers;

- programmable for 7 days;

- controls the cooler valve;

- controls the recirculation dampers;

- in case of insufficient heating power, it reduces the rotation speed of the fan blades;

- saves data in memory after power outage;

- controls the level of carbon dioxide.

On request, manufacturers equip the cabinet for automatic ventilation control with additional features:

- work without sensors;

- recording of reports on system operation;

- cold recovery;

- dispatching remote or local control.

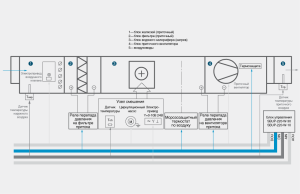

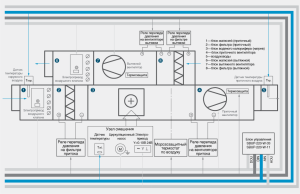

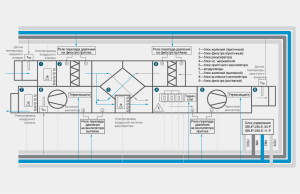

Ventilation control cabinet diagram

The widest selection of control cabinets for supply and exhaust and supply ventilation allows you to choose the best option for any type and combination of equipment.

The standard layout of the ventilation control cabinet includes:

- frequency converter;

- microprocessor controller;

- starters, circuit breakers;

- automatic switches;

- contactors;

- protective mechanisms;

- relay;

- light indicators of modes.

Frequency converters are necessary to change the speed of rotation of the fan blades and asynchronous motor, start mechanisms without jerking, providing a more favorable operating mode. Frequency control provides control over speed in both manual and automatic modes, prevents motor overloads. Reducing energy costs, and increasing system safety, extending the life of the system.

One of the important elements of the ventilation cabinet control circuit is the controller.

Controller types:

- discrete;

- analog.

Models presented on the Russian market contain programming menus in Russian. The controller's capabilities are sufficient to solve any problems that arise during the operation of ventilation systems. The most practical controllers are free programming, which allow you to organize the control of the ventilation system of any scheme.

Reliable and uncomplicated layout of the ventilation control cabinet makes it possible not to carry out its service and maintenance. Once every 6 months, the integrity of the cables and insulation, the condition of the grounding is checked. In addition, it is necessary to adhere to the rules for operating the equipment.

The shield is simple and easy to use, it is made from modern and high quality materials. Indication is provided by LEDs that glow evenly and brightly.

Rules for placing ventilation control cabinets

Ventilation control cabinets are designed for continuous operation, withstand the temperature range of -10 ... + 55 degrees Celsius.

Supply ventilation control cabinets are manufactured in metal or plastic cases.

The closed metal case has a degree of protection IP31, the plastic one - IP45.

The cabinet for controlling the supply and exhaust ventilation is powered from 220 or 380 Volts with mandatory grounding and a current frequency of 50 Hz.

Supply ventilation control cabinets are installed only indoors, away from sources of moisture, dust, heat and active chemicals.

It is forbidden to use the ventilation control cabinet in high humidity, wet conditions, exposure to direct sunlight, radio or magnetic interference.

The optimal place for placing the cabinet is in the electrical room or control room.

Video about wiring the control cabinet: