The gas boiler room of a private house is necessarily provided with ventilation in accordance with state standards and SNiP. Liquefied and natural gas can cause fire or explosion, therefore, increased safety requirements are imposed on the premises. Compliance with all ventilation standards is mandatory, they should be taken into account when designing a private house or choosing a room for a boiler room. Read about how to make ventilation in a boiler room correctly in our material.

Do I need ventilation in a gas boiler room

Even a small amount of carbon monoxide can worsen the well-being of residents. Chronic fatigue, headaches and pain in the eyes are the least that people who often inhale combustion products feel. Explosive and flammable fuel leaks are no less dangerous.

Poorly designed ventilation not only threatens human life and health, but also reduces equipment performance.

The operation of a gas boiler is possible with a constant supply of oxygen to the boiler and timely removal of combustion products. With a lack of air, the fuel burns worse. Consuming the same amount of gas, the boiler produces less heat in a poorly ventilated room.

Weak exhaust ventilation in a boiler room with a floor-standing gas boiler leads to accumulation of burning and soot inside the equipment, air duct cross-sections decrease, draft deteriorates and some of the combustion products are drawn into the room.

Gas boilers use air from the boiler room. If the boiler room is separated from the main house by wooden leaking doors or old-style windows in it, there is enough air entering through the cracks of the frames. But if modern windows and doors are installed, air will not come from outside. When the fuel burns, the air in the room will be discharged, and the boiler efficiency will decrease. The fumes from the boiler can go to the boiler room and from there to the living rooms. Therefore, you need to think about how to make the ventilation of the boiler room.

Requirements for ventilation in a private house with gas

In addition to the presence of ventilation, special requirements are imposed on the gas boiler room.

The boiler room may be equipped with:

- in the annex to the cottage;

- in the attic;

- in a separate building;

- in a specially designated room.

If the equipment is designed for LPG, a basement or basement will not work. Liquefied gas has a higher specific gravity than air. Therefore, in the event of leaks, it sinks to the lowest parts of the house and here it can explode. This feature of the fuel must be taken into account before doing ventilation in the boiler room.

Low-power gas boilers (no more than 30 kilowatts) do not require the equipment of a special boiler room, you can hang or install them in the kitchen if the room meets the following requirements for ventilation of the boiler room of a private house:

- area from 15 sq. meters;

- ceiling height at least 2 m 20 cm;

- window area from 3 sq. cm per 1 cubic meter of room volume;

- the window opens or has a window;

- holes are made in the lower part of the door for air flow from adjacent rooms;

- the equipment is installed near a wall made of non-combustible material at a distance of at least 0.1 m.

According to the requirements, forced ventilation in the boiler room in a private house is required. If the power of the equipment is higher than 30 kilowatts, a separate boiler room is equipped.

Gas boiler room ventilation standards according to SNiP

All requirements for ventilation of a gas boiler room are set out in SNiP 2.04.05, II-35.

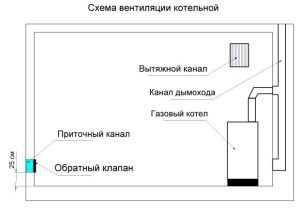

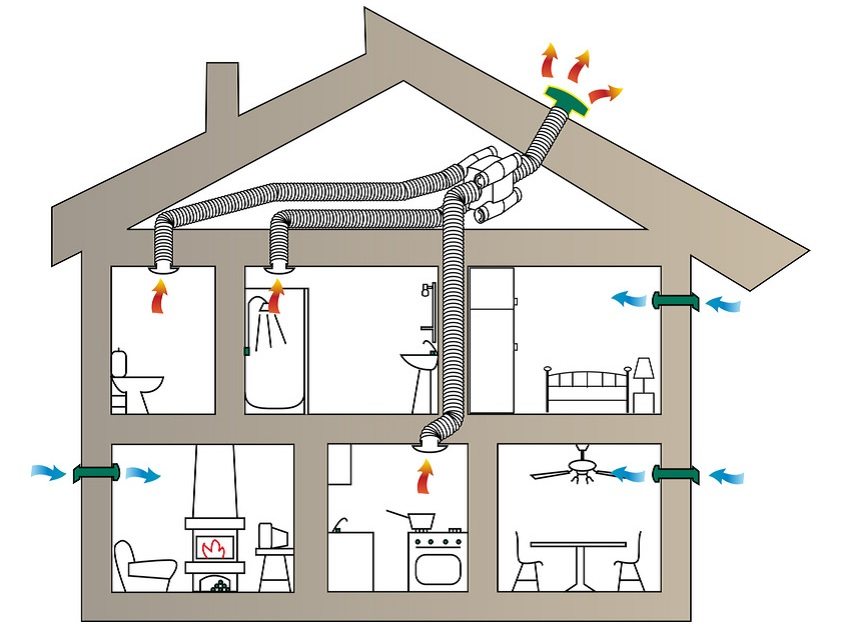

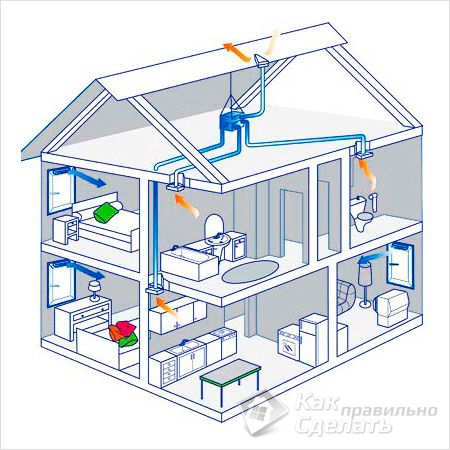

- There must be ventilation in the gas boiler room, the air duct outlet is located on the ceiling;

- Near the chimney channel, another one breaks through, 30 cm below. It serves to clean the chimney;

- Air inflow is provided from the street through the ventilation duct or from the adjacent room through the openings in the lower part of the door;

- The ventilation air supply is calculated based on the boiler output:

- inflow from the street: for 1 kilowatt of power - from 8 sq. centimeters of air;

- inflow from an adjacent room: for 1 kilowatt of power - from 30 sq. centimeters of air.

The rest of the rules for equipping a boiler room in a private house can be found in the relevant regulatory documents.

Natural ventilation with gas boiler

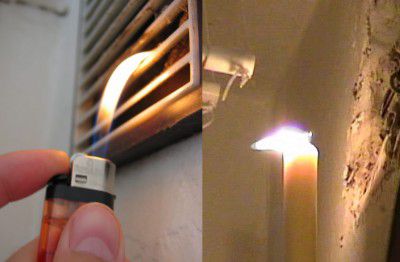

Usually, natural draft is used to ventilate a gas boiler room in a private house. So, with a boiler with a capacity of up to 30 kilowatts, there is enough airflow with a diameter of 15 cm for the inflow. A plastic pipe is inserted into the airflow, from the outside the entrance is covered with a metal mesh from the penetration of rodents and debris. Inside, a check valve is attached to the pipe, which prevents air from being drawn out into the street.

The hood is also done. An umbrella is attached to the upper end of the chimney to protect it from rain and snow. Some craftsmen also install a check valve on the chimney so that air does not enter the house through it.

In order for clean air to enter directly into the combustion chamber, the supply air duct is arranged behind the fuel compartment. The chimney is placed directly above the boiler, where the combustion products rise.

The given ventilation device for the boiler room of a private house is very simple in execution and in most cases is quite effective. But the system cannot be controlled and this is its main disadvantage. According to SNiP ventilation in the boiler room, the air must be renewed three times per hour. Air exchange with a natural ventilation system of the boiler room cannot be calculated. In addition, air exchange depends on pressure, outdoor air temperature and wind strength.

Chimney for ventilation of a gas boiler room

A chimney is one of the most important elements of a competent ventilation device for a boiler room in a private house. Therefore, it is necessary to dwell on its design separately.

SNiP ventilation in the boiler room is also developed for chimneys:

- The chimney does not allow gas and fumes to pass through. No combustion products should penetrate into the air of the boiler room. To increase the tightness of the chimney, some owners plaster it or insert asbestos-cement inside a metal pipe. Its diameter depends on the power of the boiler;

- The chimney pipe must extend beyond the level of the ridge so that the draft is sufficient. The chimney outlet must rise 2 - 5 meters above the roof ridge, otherwise suction is possible;

- The diameter of the ventilation chimney in a gas boiler room must be larger than the diameter of the chimney of the boiler itself and depends on its power. You can use the following proportions:

- with a boiler power of 24 kW - diameter 120 mm;

- at 30 kW - 130 mm;

- at 40 kW - 170 mm;

- at 55 kW - 190 mm;

- at 80 kW - 220 mm;

- at 100 kW - 230 mm.

For those who decide to equip the ventilation of the boiler room of their own private house with their own hands, simple rules will help:

- the section of the chimney pipe is indicated in the boiler passport;

- the chimney is made of sheet metal (galvanized or stainless steel). The chimney has a circular cross-section of the same diameter along its entire length and an inspection window for cleaning;

- the chimney should have no more than three turns or bends.

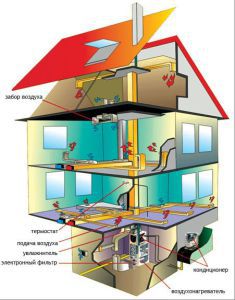

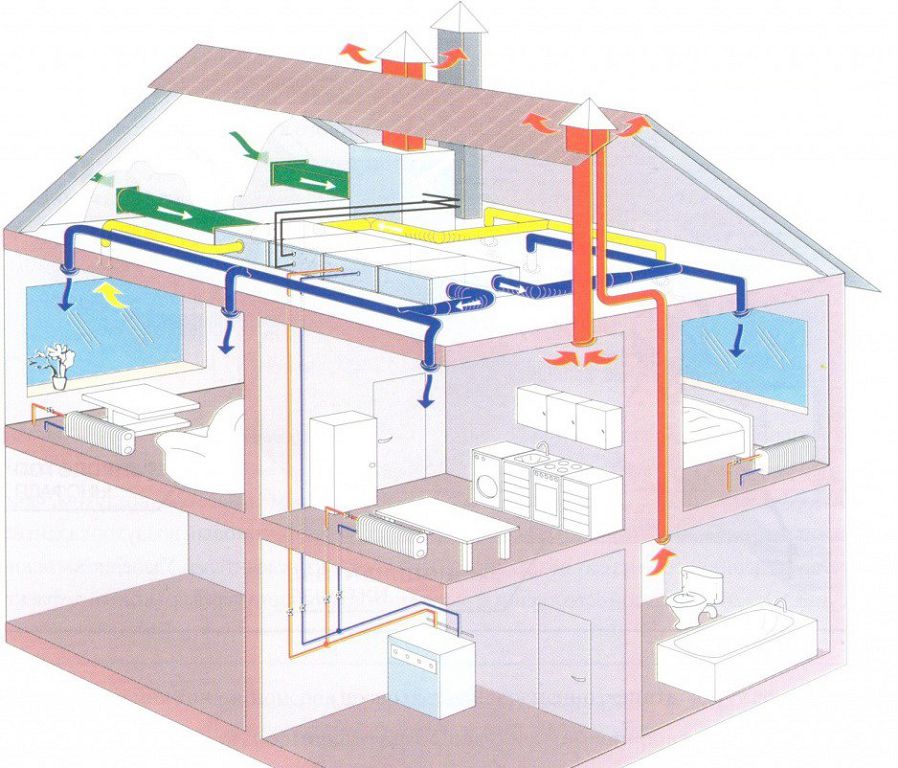

Boiler room artificial ventilation

If the natural ventilation system in the gas boiler room of a private house cannot be equipped, they resort to mechanical traction.

Artificial ventilation is powered by fans. Duct fans are usually used, which are selected depending on the cross-section of the ventilation ducts.

When calculating ventilation in a boiler room with a floor-standing gas boiler, the fan power is selected with a 20 - 30% margin at the highest load. The power also depends on the number of bends in the duct, its section and length.

The simplest method of calculating with your own hands the ventilation of the boiler room of a private house:

(W * H * D) * 3 = the volume of air to be replaced in one hour, here:

Sh - the width of the room,IN - ceiling height,D - the length of the room.

By equipping ventilation in the boiler room of a private house with your own hands, you can save money. For this, the fan is installed only for supply or exhaust. But the most reliable way is the complete mechanization of air exchange.

Experts recommend using fans in copper or aluminum casings that are resistant to melting and fire in boiler rooms with floor gas boilers.

The efficiency and economy of ventilation is increased due to the automatic control system. The automatics starts the fans at the same time as the boiler starts up. And when the firebox does not work and there is nothing to draw out, the fans stop.

In some cases, the ventilation of the boiler room of a private house is arranged in conjunction with air conditioning, at the same time providing a comfortable air temperature.

A video will help you to correctly calculate the ventilation of a gas boiler room:

You refer to SNIPs, and in the pictures you place the inflow at a height of 25 cm from the floor. Although in the snip it is written in black and white. Supply channels should be located at a height of NOT LESS than 1 meter from the level of the snow cover and NOT LESS than 2 meters from the ground level. Well, what nafig 25cm? Where did you get this from?