With their almost weightless lightness, plastic ventilation pipes never cease to amaze modern homeowners. At the same time, some skeptics still have a doubt: can plastic really be as strong as metal? We will not speak about the widest scope of plastic applications, but in the manufacture of ventilation systems from plastic pipes, light and strong plastic products will in no way yield to heavy and bulky metal air ducts, and in some ways even give them a head start.

Household plastic ventilation

In the conditions of our current reality, ventilation in a private house made of plastic pipes is becoming much more profitable than using tin and aluminum air ducts. Plastic ventilation pipes, both round and rectangular, are pleasantly distinguished by their aesthetically perfect appearance. The buyer can choose products of exactly the color that will be in harmony with the interior range in his house. The cost of plastic air ducts is significantly less than their metal counterparts, and the installation of ventilation from plastic pipes with your own hands is extremely simple and affordable even for a non-professional.

In recent years, plastic pipes for ventilation have managed to become the leaders in terms of their production and sales figures. This indicates that many buyers have already appreciated the reliability and ease of use of plastic ventilation pipes. We, as consumers, are offered not only plastic ventilation pipes for hoods, but in addition to them a full set of adapters, couplings, plugs, grilles and other components of the ventilation system in a private house made of plastic pipes. Shaped elements of the corresponding configuration allow, if necessary, to make articulation of round in cross-section air ducts with rectangular ones.

According to the type of material from which they are made, plastic ventilation pipes are of different types, slightly differing in individual properties:

- polyethylene - known for their flexibility and wear resistance;

- polyvinyl chloride (PVC) - with a high threshold of resistance to flammability and insensitive to UV radiation;

- polypropylene - characterized by exceptional strength and chemical inertness to aggressive substances.

Plastic air ducts for ventilation

Traditionally, galvanized sheet served as the material for the construction of ventilation ducts in private houses, and aluminum was also used. But ever since lighter, less expensive plastic ventilation pipes have become available, they have been unconditionally favored by engineers and homeowners.

You can also appreciate a number of advantages that, due to their physical nature, plastic pipes have in contrast to their metal competitors:

- Corrosion resistant. The main difference between plastic and iron is the absence of rust, so the plastic ventilation pipe for the hood will be indispensable in conditions where dampness is constantly observed;

- Smooth inner surface. Manufacturing technology ensures perfect smoothness of plastic pipes for ventilation systems.This indicator is especially important, because the slightest roughness of the inner surfaces prevents the free movement of the air flow through the pipes;

- Low weight. To bring the entire set of plastic pipes and fittings from the store, you don't have to hire a multi-ton truck. And whatever the dimensions of the plastic pipes, they can be very easily lifted and turned when installing the ventilation system;

- Ease of installation and maintenance. Installing parts and assemblies of plastic ducts is much easier than fiddling with heavy metal boxes. Periodic inspection and cleaning of ventilation ducts will also not be difficult for you;

- Comparative cheapness. The cost of inexpensive plastic compared to metal successfully solves your problem, how to make ventilation from plastic pipes cheaper.

Plastic pipes are unable to withstand temperatures above 80–90 degrees, so it is undesirable to use them for ventilation of premises such as a sauna, bakery, boiler room, etc.

Shape and dimensions of plastic air ducts

In private houses, ventilation is made of plastic pipes, round or rectangular. There is also an intermediate version of air ducts with an oval cross-section. Round air duct pipes can be not only rigid and smooth, but also corrugated, their flexibility allows installation of ventilation ducts of complex configuration. The choice of the shape of the duct is determined in accordance with the peculiarities of its location, but the design project is also of considerable importance.

Manufacturers produce ventilation pipes, the dimensions of which are made standard. Unification of pipe sizes is necessary so that it is convenient to select the appropriate fittings for them. To lay air ducts in an ordinary cottage, it is enough to use plastic ventilation pipes of the following dimensions:

The maximum length of commercially available plastic ventilation pipes reaches 2.5 meters, which allows them to be installed without unnecessary use of joints.

When making a plan on how to make ventilation from plastic pipes, do not forget that plastic rectangular ventilation pipes create slightly more resistance to air flow than circular air ducts.

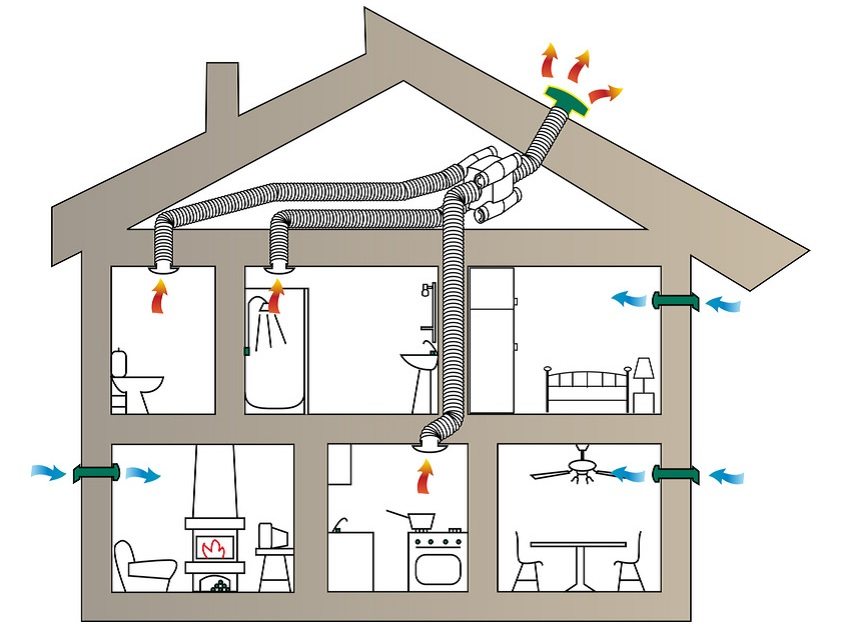

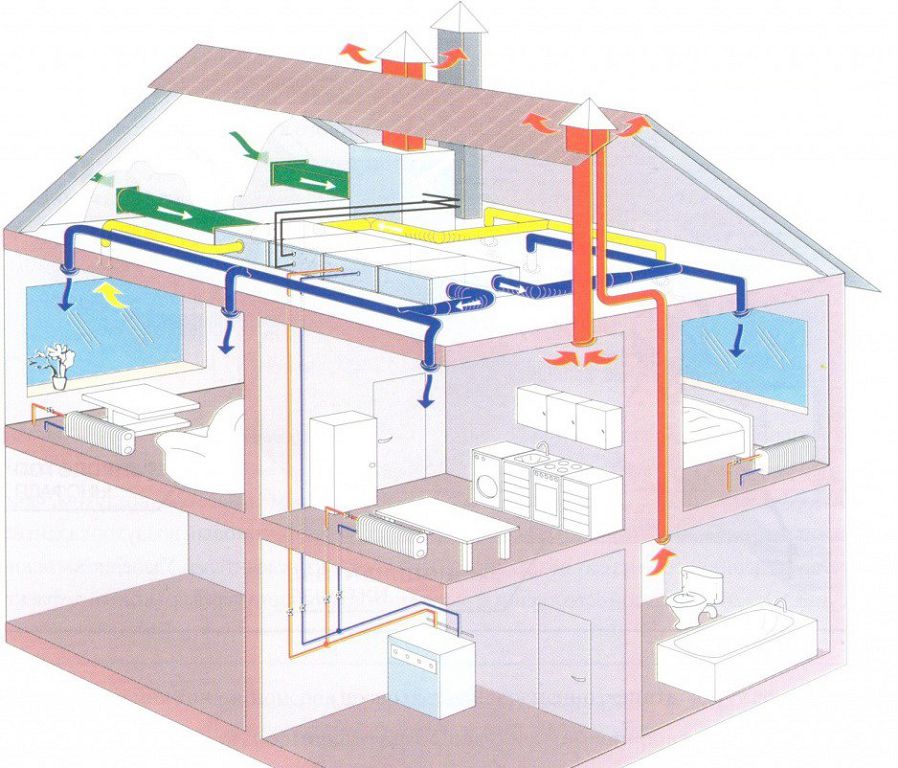

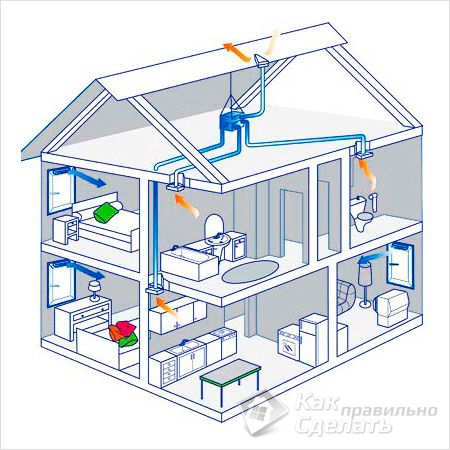

How to plan plastic ventilation in your home

If you have made the decision to build ventilation from plastic pipes at home with your own hands, take it responsibly. Before getting down to business, entrust the design of all proposed hood elements to an experienced specialist. Only a specialist with experience and qualifications will be able to most accurately calculate the performance of the system and make an estimate.

Discuss some important points with the designer:

- exhaust air extraction from premises of various purposes (kitchen, bathroom and living room) should take place through separate air ducts;

- to remove accumulating condensate from the exhaust ducts, it is necessary to equip special holes in them, even though the plastic pipes used for ventilation are not afraid of moisture;

- if you cannot avoid laying long horizontal sections of air ducts, then you will have to equip them with fans for forced exhaust;

- so that the fan does not waste air from one room to another, check valves must be installed in certain places of the ventilation system made of plastic pipes.

When constructing ventilation from plastic pipes, you will certainly have to use couplings, bends, tees and other parts to connect them.

But at the same time, count so that each plastic ventilation pipe runs evenly, if possible, without unnecessary turns. The duct system should also not have too many joints, try to use solid pipes as much as possible. You will have two reasons to strive for the optimal configuration of ventilation ducts:

- Each of the joints and sharp turns of the plastic ventilation pipe reduces the airflow rate and increases the noise.

- Additional costs for numerous fittings lead to an increase in the cost of the entire system.

After drawing up the project, choose the size and shape of plastic pipes for room ventilation. If the project provides for the option of open laying of air ducts in the room, then you will have to select them in accordance with the color of the interior. But usually homeowners try to hide any ventilation pipe, even plastic, under the ceiling or decorative casing.

Another thing is a plastic ventilation pipe for the hood. Open air ducts are more often used here, and so that they do not violate the harmony of design, pipes for ventilation of the kitchen can be painted in the selected color if desired. In the kitchen, ventilation from plastic pipes is especially relevant, and making it with your own hands is not only easy, but also prestigious.

Since plastic has a tendency to accumulate static electricity, dust and grease droplets from the stove stick to it. Therefore, when installing plastic pipes for kitchen ventilation, it is advisable to treat them from the inside with an antistatic compound.

Technological aspects of the plastic ventilation device

At first glance, the question of how to make your own ventilation from plastic pipes may seem complicated. In reality, this kind of work is not difficult to cope with. You just need to familiarize yourself with some of the recommendations and follow them during installation work.

- You can cut plastic pipes into pieces of the desired size right at the place where you will mount them;

- There are two ways to connect plastic pipes: one-piece (using welding) and separable (using fittings and flanges);

- For the construction of air ducts, it is preferable to use detachable connections in order to facilitate the possibility of their repair if necessary;

- Connect the air duct elements and their mutual fastening using the fasteners and silicone sealant supplied with them;

- Collect complex components of the system in a place convenient for work on the floor, and then lift to the installation site;

- Fasten the air ducts to the ceiling with special clamps. For lightweight plastic pipes, one fastener is sufficient for the entire integral section. Heavier and larger plastic rectangular ventilation pipes will have to be fixed every one and a half meters.

A video lesson will help you understand the specifics of self-installation of a kitchen duct.

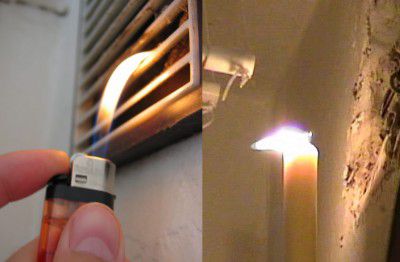

In conclusion, we advise you to note an important sign that will help you recognize whether you managed to correctly mount the ventilation from plastic pipes. Notice if your windows sweat in cold weather. If the ventilation built by your hands ensures good air exchange, there will be no fogging of the windows. Otherwise, it is possible that mistakes were made during the design of the system.

May the windows never sweat in your house, and all household members will be provided with fresh air all year round!