Safe use of furnace and gas equipment is possible only with timely removal of combustion products and continuous air exchange inside the premises. This and some other functions are performed by chimneys of various types: from elegant decorations of country villas to giant monsters - indispensable attributes of industrial zones.

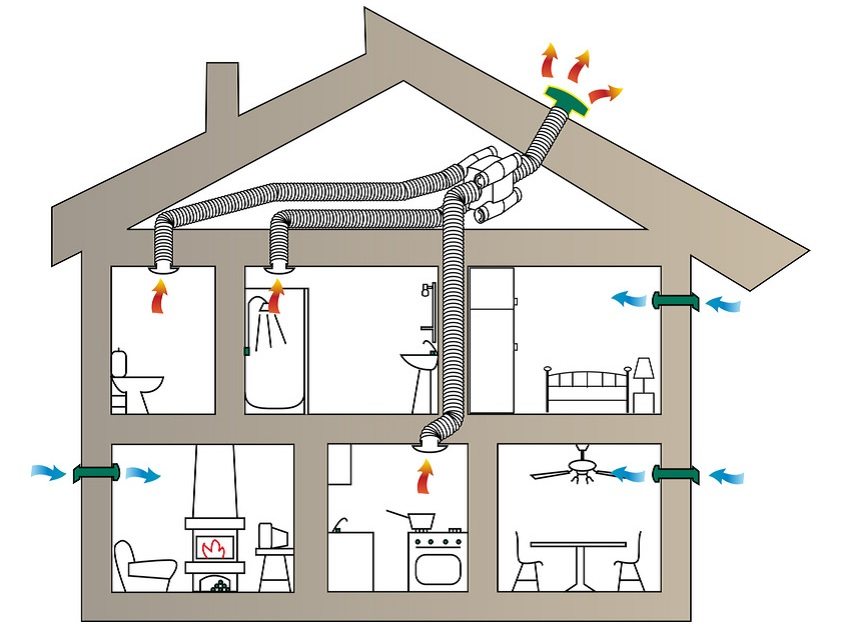

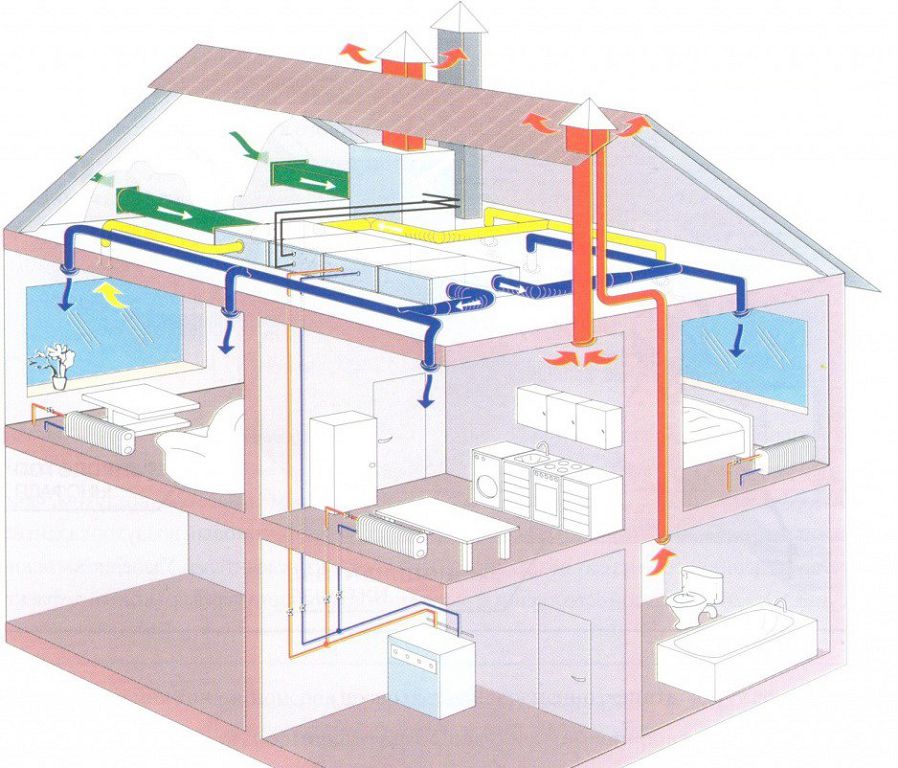

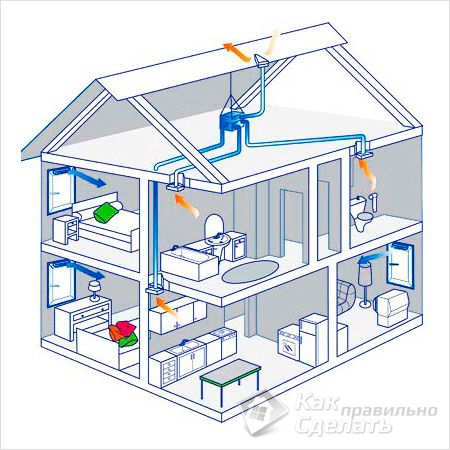

Natural draft principle

The outflow of gas combustion products from boilers, columns and furnaces is carried out through ventilation and chimneys by means of natural draft. Traction is provided when the temperature difference between the street and the house. The higher the ventilation duct or chimney and the greater the temperature difference, the more intensively the chimney pulls. Therefore, natural ventilation works best on the ground floors of multi-storey buildings even during the cold season.

The temperature of the combustion products above the working stove is about 200 degrees. The air temperature in the ventilation and chimneys is not more than 25 degrees and therefore the draft is very weak. In summer, when the temperature outside is higher than indoors, the draft can "tip over", that is, air is sucked into the apartments from the ventilation.

To a large extent, the efficient operation of the system depends on the frequency of checks of the flue and ventilation ducts.

Reasons for reduced thrust:

- contamination of the inner walls of the channels;

- roughness, narrowing of the walls;

- increase in the diameter of the channel;

- air leaks.

A significant part of the energy of the air moving through the channel is spent on resistance to friction against the walls, when turning and reducing the diameter of the channel. The head loss indicator depends on the masonry of the smoke or ventilation duct, its length and condition. In the presence of protrusions, build-up of dust and roughness, the resistance increases. Therefore, timely inspection and cleaning of ventilation and smoke ducts increases traction.

In large-diameter ducts, even with perfect observance of the rules for the safe operation of chimney and ventilation pipes, the draft is reduced, since the combustion products are cooled faster.

With air leaks in the channel, the thrust also drops, since the air temperature in the channel decreases, and its volume increases. Therefore, all pipe service hatches must be kept closed.

The draft in the chimneys during the operation of the boiler or stove is about 14 Pa. It is much lower in ventilation ducts. The opening of the air vents in apartments, the direction and strength of the wind, and even the location of neighboring houses affect the draft. Ventilation and chimneys should not be located in the area of the wind back. This is the space below the line from the highest point of the nearest building to the horizon at a 45 degree angle.

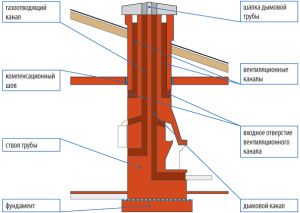

Construction of ventilation pipes and chimneys

According to the rules for the operation of chimneys and ventilation pipes, they are arranged inside the house to maintain the temperature of the exhaust air. You can arrange ventilation and smoke channels outside, then they need insulation.

The masonry of ventilation and smoke ducts consists of clay bricks or heat-resistant concrete (asbestos cement).The thickness of the brickwork is from 12 cm, the concrete wall of the ventilation or smoke channel is more than 6 cm. The SNiP states that ventilation and smoke channels are arranged only vertically, without transitions and horizontal sections.

Pocket device (holes) for cleaning the chimney

Openings for cleaning and a pocket with a depth of 25 cm are left at the base of the chimney. The openings are covered with doors and lined with bricks installed on the rib. The laying is done on a clay solution. In asbestos-cement pipes, a leaf is left for cleaning.

The pocket is necessary so that when the masonry is destroyed, the fragments of brick do not block the inlet, falling slightly lower. All the garbage that gets into the chimney also accumulates in the pocket. If you do not provide for a pocket, debris will gradually reduce the cross section of the chimney and worsen draft.

Unsuitable materials for the construction of smoke and ventilation ducts:

- slag concrete;

- silicate, perforated, slotted brick;

- coarse-grained materials.

Although silicate bricks withstand high temperatures well, they are destroyed by carbon dioxide and wet fumes. If there are no other materials, SNiP requires a device in the ventilation and smoke channel of an internal cladding made of red brick 13 cm thick.

Chimneys can be:

- mounted (from asbestos-cement pipes inserted into each other);

- solid (brick).

Packed pipes are distinguished by smooth inner walls, they are supported on fireplaces or stoves with powerful (no thinner than 1/2 brick) walls. If the pipe is heavy, a reinforced concrete slab is installed on the furnace ceiling and the pipe is already attached to it.

Asbestos-cement packed pipes are much lighter than brick ones, they do not need to be disassembled during overhaul, they are quickly installed.

A brick chimney requires a special foundation, which is laid to a depth exceeding the depth of soil freezing.

When erecting low-rise buildings, prefabricated chimneys are used, which are built into the wall or form a riser. The chimney walls are made of heat-resistant concrete.

In places where the chimney passes through the roof, it is necessary to leave an opening with a width of at least 13 cm. The connection of the chimney with the roof is covered with a stainless steel apron.

The chimney can have a slope of up to 30 degrees with an offset to the side of no more than 100 cm. Such segments should be of the same cross-section, equal to the cross-section of vertical segments with smooth walls.

Brick chimney heads are covered with plaster by 20 cm to protect from precipitation. Deflectors and umbrellas are not installed on chimneys.

Chimneys of gasified buildings

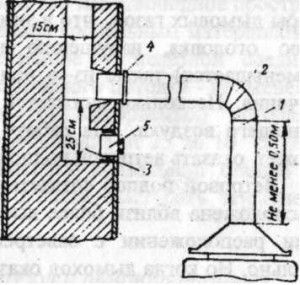

Ventilation and smoke ducts of gasified premises should rise above a flat roof by 50 cm or more. On a pitched roof 50 cm or more above the rib or to the height of the rib with a distance from the rib to the chimney of 1.5 - 3 meters.

The height of the chimneys of the gasified rooms must be equal to the height of the exhaust ducts.

Heating equipment is connected to the system of ventilation and smoke ducts in the gasified room through metal adapters. The length of the vertical adapter must be from 50 cm. If the height of the room is less than 2 m 70 cm and draft stabilization is used, the vertical adapter can be shortened to 25 cm. The total length of the horizontal adapters can be up to 3 m in new buildings or up to 6 m in existing buildings.

A slope towards the boiler from 0.01 is allowed. Pipes must be fixed rigidly without the possibility of sagging. The pipe bends are inserted into each other along the smoke path and overlap by 1/2 of the chimney diameter.

The metal adapter is tightly attached to the chimney without protruding beyond the walls of the channel.

If the pipe is made of sheet metal, it must be treated with a heat-resistant varnish.

The pipe is attached to the chimney, leaving a 25 cm pocket and a control hatch, just like when building a chimney.If the appliance is not equipped with a draft stabilizer, a 15 mm perforated damper is required, through which the oven is ventilated during periods of inactivity.

When retrofitting old chimneys from ovens for gas appliances, poor draft is often observed. The furnaces are fired for a longer time and the temperature of the combustion products is much higher than during the operation of a gas boiler, therefore, the discharge of air from the combustion of gas is not enough.

Chimney requirements

part of the future chimney column Structures adjacent to the chimney are protected with a layer of non-combustible material;

- During construction, each furnace or gas heater is equipped with its own ventilation or smoke duct;

- In already functioning buildings, it is allowed to discharge emissions from two stoves or boilers into one chimney if they are located at a distance of more than 0.5 meters from each other;

- The laying of ventilation ducts or chimneys should be without ledges and outlets with the most smooth inner walls. Such laying is done by specialists using buoys and mopping with a wet rag;

- Brick laying is carried out on a lime-cement or lime-sand mixture. The thickness of the seams is up to 1 cm;

- The pipe above the roof is laid exclusively on cement mortar;

- The outer walls of the chimneys in the attic are plastered and whitewashed;

- The main requirement for a chimney is its density;

- Between the smoke and ventilation ducts, there should be partitions with a thickness of 1/2 brick;

- The area of the inner diameter of the chimney must be equal to the area of the diameter of the outlet of the heating device. In masonry, the minimum section is 1/2 bricks per 1/2 bricks, and for a finished pipe, at least 15 cm.

Chimney operation

The rules for the safe operation of chimneys and ventilation pipes require periodic cleaning and inspection. Without cleaning, a long-term operating chimney becomes a potential source of fire or poisoning for residents. The need for cleaning ventilation and smoke channels is determined by routine inspections.

A chimney made of bricks or made of asbestos-cement pipes loses its appearance after a while and works worse. Soot and soot accumulate on the inner walls, the chimney clearance decreases and the draft decreases. But there is another danger: the products of combustion can ignite. Substances released by soot destroy pipe material and masonry seams. The tightness of the chimney decreases, the fuel does not burn completely, and the draft deteriorates.

Only periodic checks of smoke and ventilation ducts will help to avoid dangerous situations.

If heating equipment is used every day, the frequency of checking and cleaning the ventilation and flue ducts is 8 weeks. If the stove is melted from time to time, the condition of the chimney must be monitored twice a year: in the fall before the start of the heating season and in spring.

Checking chimneys

Inspection of smoke and ventilation ducts is carried out in the following cases:

- when converting stoves to gas fuel;

- when connected to the chimneys of gas boilers;

- if it is necessary to diagnose the condition of the chimney and poor draft.

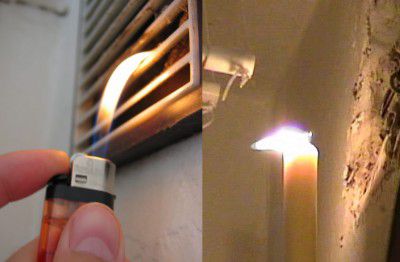

Purpose of checking ventilation and flue ducts:

- compliance of the materials of the masonry of the smoke or ventilation duct and the device with the requirements of SNiP;

- the presence of blockages;

- the presence of traction;

- the density of the chimney walls;

- the condition and presence of partitions separating the adjacent building structures;

- the condition of the head and its location in relation to the roof, buildings and trees.

Progress of checking ventilation and flue ducts:

- To determine the blockages in the chimney from above, a load in the form of a sphere, weighing 3 kg and measuring up to 10 cm, is lowered into it. If the load passes unhindered, the channel is clean;

- To determine the isolation and density of the channels, the smoke method is used. A burning tow soaked in gasoline or a bundle of straw is put into the window for cleaning, which gives off abundant smoke when burning. From above, the outlet of the chimney is tightly covered. If the smell of smoke appears in nearby rooms or channels, then the walls of the channel are not dense;

- The cleanliness of the channel walls is inspected by lowering an electric light bulb with a power of up to 500 W into the chimney. The density of the walls is determined at the same time. If there is light in the adjacent channels, then there are gaps.

Cleaning is carried out based on the results of the inspection of the ventilation and flue ducts. She may be:

- mechanical;

- chemical.

Mechanical cleaning is carried out with brushes and metal wire brushes. Under the weight of the load, they descend on ropes into the chimney and scrape off all deposits from the walls. Some pipes (for example, ceramic) are difficult to clean - they can crack.

Dry cleaning is safer. In the firebox, a "chimney sweep log" is burned, which burns out soot on the walls of the chimney. The material is impregnated with a chemical composition that decomposes soot and soot. But dry cleaning does not cope with thick deposits, therefore it is used as an auxiliary or preventive.

Experts recommend using dry alder or aspen firewood as a "chimney sweep log". They burn at very high temperatures and burn away soot.

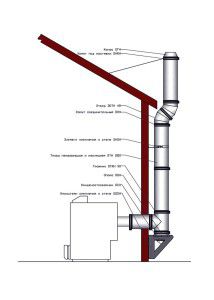

Industrial chimneys

The purpose of industrial chimneys and ventilation pipes is not only in the removal of combustion products, but also in maintaining combustion in boiler units. In the recent past, most industrial chimneys and ventilation pipes were made of brickwork. Today, it is increasingly replaced by metal pipes with thermal insulation. The height of the structure can be up to 60 meters.

According to the rules of safe operation of chimney and ventilation pipes, they need periodic cleaning. Prevention is carried out at the end of the heating season. And in order to exclude accidents, scheduled inspections of ventilation and smoke channels are assigned.

They design chimneys and ventilation pipes for industry, taking into account each specific enterprise, since the task of the construction is always unique.

When designing, take into account environmental standards for the rate of dispersion of smoke and limit smoke concentrations.

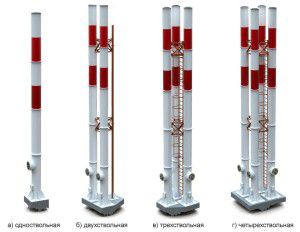

Types of industrial chimneys:

- Self-supporting metal... The cheapest are made of thermally insulated metal. They are very heavy. Can be single-barreled or multi-barreled;

- Self-supporting truss... They represent a truss column with heat-insulated gas ducts. 1 - 6 trunks are attached to one farm. The farm itself is made of rolled pipes;

- Metal columns... One powerful "shell" in which 1 - 5 trunks are hidden. Maximum height 60 m, diameter up to 3.5 meters;

- Stretching... Single-barrel metal pipe, which is attached with guy wires. Most often they are installed in industrial plants. Produced by rolling. Such a pipe will last no more than 15 years, even if all the rules for the operation of ventilation and chimneys are observed;

- Facade... The most economical option, does not need a foundation or supporting structure. Fastened to the facade, often this type of pipe is used in attached or built-in boiler houses.

The diameter of the pipes can be from 0.2 to 1.5 meters, and the height is 8 to 60 meters. There can be several gas outlet channels.

Depending on the conditions, industrial chimneys can be equipped with:

- lightning rod;

- protective lighting;

- ladders and service platforms.

If a rectangular industrial chimney is installed, the correct aspect ratio is very important. The best is considered to be 1: 1.5 with the inner corners grinded off.

The rules for the operation of smoke and ventilation pipes require their installation only on special self-supporting foundations.

And at the end, a video about dismantling industrial chimneys: