Strict requirements are imposed on working conditions in production and in industry. Various regulations must be followed. Correct fulfillment of many requirements affects the quality of the air environment. It is ensured by proper air exchange. In most industrial enterprises, it cannot be provided by natural ventilation, therefore, the installation of special hoods is required. In order to properly establish air exchange, it is necessary to calculate the ventilation.

Types of air exchange used in industrial plants

Regardless of the type of production, there are rather high demands on the air quality at any enterprise. There are standards for the content of various particles. Various types of ventilation systems have been developed to fully meet the requirements of sanitary standards. Air quality depends on the type of air exchange used. Currently, the following types of ventilation are used in production:

- aeration, that is, general ventilation with a natural source. It regulates air exchange throughout the room. It is used only in large production areas, for example, in workshops without heating. This is the oldest type of ventilation, now it is used less and less often, since it does not cope well with air pollution and is not able to regulate the temperature regime;

- local extract, it is used in industries where there are local sources of emission of harmful, polluting and toxic substances. It is installed in the immediate vicinity of the discharge points;

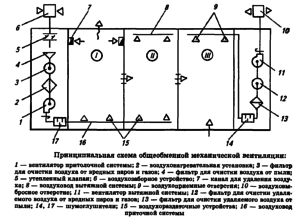

- supply and exhaust ventilation with artificial induction, used to regulate air exchange in large areas, in workshops, in various rooms.

Ventilation functions

The ventilation system currently performs the following functions:

- removal of industrial harmful substances released during work. Their content in the air in the working area is regulated by regulatory documents. Each type of production has its own requirements;

- removal of excess moisture in the working area;

- filtration of polluted air taken from the production premises;

- emission of removed pollutants to the height required for dispersion;

- temperature regulation: removal of air heated during the production process (heat is released from operating mechanisms, heated raw materials, substances that enter into chemical reactions);

- filling the room with air from the street, while filtering it;

- heating or cooling of the drawn in air;

- humidification of air inside the production room and drawn from the street.

Types of air pollution

Before proceeding with the calculation work, it is necessary to find out what sources of pollution are available. Currently, the following types of harmful emissions are found in production:

- excess heat from operating equipment, heated substances, etc.

- vapors, vapors and gases containing harmful substances;

- release of explosive gases;

- excess moisture;

- discharge from people.

Typically, in modern manufacturing, there are various types of contaminants, for example, operating equipment and chemicals.And none of the industries can do without secretions from people, since in the process of activity a person breathes, the smallest particles of skin crumble from him, and so on.

The calculation must be performed for each type of pollution. In this case, they are not summed up, but taken as the final greatest result of calculations. For example, if air is most needed to remove chemical air pollution, then it is this calculation that will be adopted to calculate the required volume of general ventilation and exhaust capacities.

Performing calculations

As you can see from the above, ventilation has many different functions. Only a sufficient number of devices can provide high-quality air purification. Therefore, during installation, it is necessary to calculate the required power of the installed hood. Do not forget that different types of ventilation systems are used for different purposes.

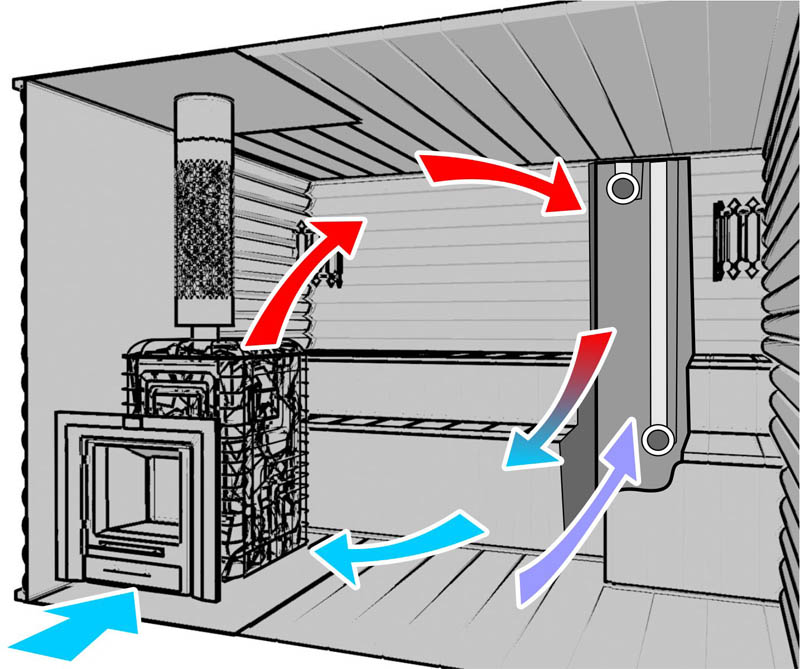

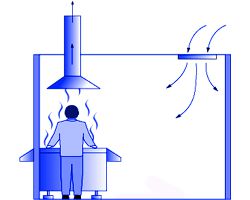

Calculation of local exhaust

If emissions of harmful substances occur in production, then they must be captured directly at the closest possible distance from the source of pollution. This will make their removal more effective. As a rule, various technological tanks become sources of emission, and operating equipment can also pollute the atmosphere. To capture the emitted harmful substances, local exhaust devices are used - suction. Usually they look like an umbrella and are installed above the source of vapors or gases. In some cases, such installations are bundled with the equipment, in others - the powers and dimensions are calculated. It is not difficult to execute them if you know the correct calculation formula and have some initial data.

To make a calculation, you need to take some measurements and find out the following parameters:

- the size of the emission source, the length of the sides, the section, if it has a rectangular or square shape (parameters a x b);

- if the source of pollution is round, it is necessary to know its diameter (parameter d);

- air velocity in the zone where the emission occurs (parameter vw);

- suction speed in the area of the exhaust system (umbrella) (parameter vz);

- planned or available height of the hood installation above the pollution source (parameter z). It should be remembered that the closer the hood is to the emission source, the more efficiently the pollutants are captured. Therefore, the umbrella should be positioned as low as possible above the container or equipment.

Calculation formulas for rectangular hoods are as follows:

A = a + 0.8zwhere A is the side of the ventilation device, a is the side of the source of pollution, z is the distance from the source of emission to the exhaust.

B = b + 0.8z, where B is the side of the ventilation device, b is the side of the source of pollution, z is the distance from the source of emission to the exhaust.

If the exhaust system is circular, its diameter is calculated. Then the formula will look like this:

D = d + 0.8z, where D is the hood diameter, d is the pollution source diameter, z is the distance from the emission source to the hood.

The exhaust device is made in the form of a cone, and the angle should not be more than 60 degrees. Otherwise, the efficiency of the ventilation system will decrease, as zones are formed along the edges where air stagnates. If the air speed in the room is more than 0.4 m / s, then the cone must be equipped with special folding aprons in order to prevent the dispersion of emitted substances and protect them from external influences.

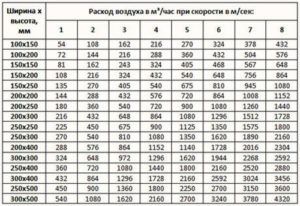

It is necessary to know the overall dimensions of the hood, since the quality of air exchange will depend on these parameters. The amount of extract air can be determined using the following formula: L = 3600vz x Sz, where L is the air flow rate (m3/ h), vz is the air speed in the exhaust device (a special table is used to determine this parameter), Sz is the opening area of the ventilation unit.

If the umbrella has a rectangular or square shape, then its area is calculated by the formula S = A * B, where A and B are the sides of the figure. If the exhaust device has the shape of a circle, then its size is calculated by the formula S = 0.785Dwhere D is the diameter of the umbrella.

The results obtained should be taken into account when designing and calculating general ventilation.

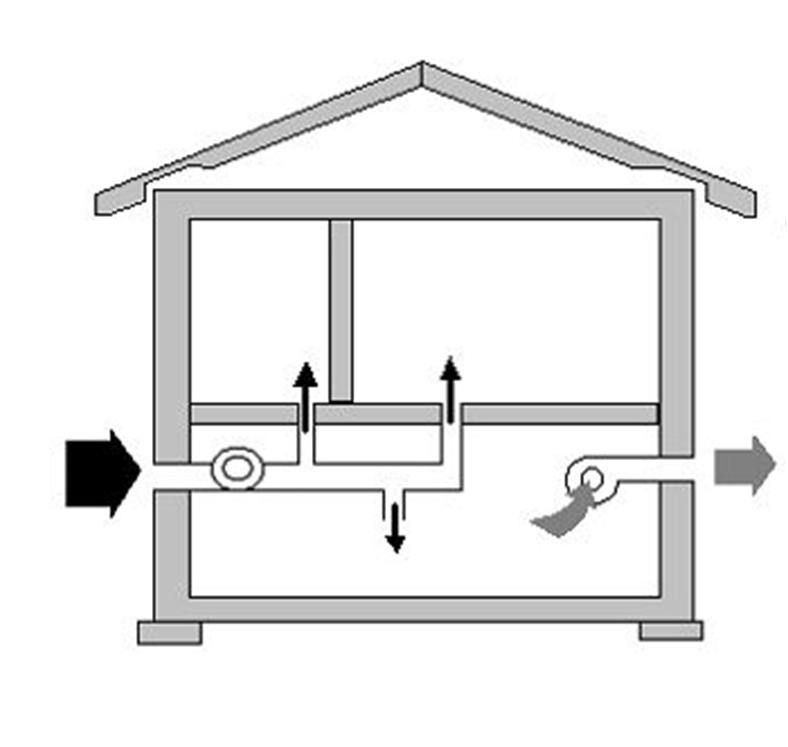

Calculation of general exchange supply and exhaust ventilation

When the required volumes and parameters of local exhaust are calculated, as well as the volumes and types of contamination, you can begin to calculate the required volume of air exchange in the production room.

The easiest option is when there are no harmful emissions of various types during work, and there are only those pollutants that people emit. The optimal amount of clean air will ensure normal working conditions, compliance with sanitary standards, as well as the necessary cleanliness of the technological process.

To calculate the required air volume for working people, use the following formula: L = N * m, where L is the required amount of air (m3/ h), N is the number of people working at the production site or in a specific room, m is the air consumption for breathing of 1 person per hour.

The specific air consumption per 1 person per hour is a fixed value, indicated in special SNiPs. The norms indicate that the volume of the mixture for 1 person is 30 m3/ h, if the room is ventilated, if there is no such possibility, then the rate becomes twice as large and reaches 60 m3/ h

The situation is more complicated if there are various sources of emission of harmful substances on the site, especially if there are many of them and they are dispersed over a large area. In this case, local extracts will not be able to completely get rid of harmful substances. Therefore, in production, they often resort to the following technique.

Emissions are dispersed and then removed using a general exchange supply and exhaust ventilation. All harmful substances have their own MPCs (maximum permissible concentrations), their values can be found in special literature, as well as regulatory documents.

You can calculate the amount of harmful substances in the air using the following formula:

L = Mv / (ypom - yp), where L is the required amount of fresh air, Mw is the mass of the emitted harmful substance (mg / h), reference is the specific concentration of the substance (mg / m3), yn is the concentration of this substance in the air entering through the ventilation system.

If several types of pollutants are emitted, then it is necessary to calculate the required amount of clean air mixture for each of them, and then sum them up. The result will be the total volume of air that must be supplied to the production area in order to ensure that sanitary requirements and normal working conditions are met.

Ventilation calculation is a complex matter that requires great accuracy and special knowledge. Therefore, for self-calculations, you can use online services. If in production it is necessary to work with hazardous and explosive substances, it is better to entrust the calculation of ventilation to professionals.