Deflectors are attached to the outlets of natural ventilation pipes over the roofs of small enterprises, public buildings, and residential buildings. Using the wind pressure, the deflectors induce draft in the vertical ventilation ducts. The second important function of the deflectors is to prevent rain and snow from entering the ventilation shafts. Dozens of models of ventilation deflectors have been developed, some of which are described below. The simplest options for deflectors can be made by hand.

- Ventilation deflector device

- The principle of operation of the ventilation deflector

- Deflector types

- Deflector ASTATO

- Static deflector with ejection fan

- Deflector-weather vane

- Rotary turbine

- DIY ventilation deflector

- Step 1. Calculation of deflector parameters

- Step 2. Making a deflector

- Step 3. Installing the deflector

- Ventilation deflector selection

Ventilation deflector device

Any type of ventilation deflectors contains standard elements: 2 cups, brackets for the lid and a branch pipe. The outer glass expands downward, and the lower one is even. The cylinders are put on top of each other, a cover is attached above the top. At the top of each cylinder are baffles in the form of rings that change the direction of air in a ventilation deflector of any size.

The rebounds are installed in such a way that the wind on the street creates a suction through the spaces between the rings and accelerates the removal of gases from the ventilation.

The device of the ventilation deflector is such that when the wind is directed from below, the mechanism works worse: being reflected from the cover, it is directed towards the gases that go out into the upper opening. Any type of ventilation deflectors has this disadvantage to a greater or lesser extent. To eliminate it, the lid is made in the form of 2 cones, fastened with bases.

When the wind is from the side, the exhaust air is discharged from the top and bottom at the same time. When the wind is from above, the outflow is from below.

Another device for the ventilation deflector is the same glasses, but the roof is in the shape of an umbrella. It is the roof that plays an important role here in redirecting the wind flow.

The principle of operation of the ventilation deflector

The principle of operation of the exhaust ventilation deflector is very simple: the wind hits its body, is cut by the diffuser, the pressure in the cylinder decreases, which means that the draft in the exhaust pipe increases. The more air resistance the deflector body creates, the better the draft in the ventilation ducts. It is believed that deflectors work better on ventilation pipes installed slightly at an angle. The efficiency of the deflector depends on the height above the roof level, the size and shape of the body.

The ventilation deflector is frozen on the pipes in winter. On some models with a closed case, ice is not visible from the outside. But with an open zone of the duct, ice appears from the outer part of the lower glass and is immediately noticeable.

A properly sized baffle can increase ventilation efficiency by up to 20%.

Most often, deflectors are used in natural draft ventilation, but sometimes they reinforce forced ventilation. If the building is located in areas with infrequent and weak winds, the main task of the device is to prevent a decrease or "overturning" of draft.

Deflector types

Choosing a ventilation deflector, you can get confused by the variety.

The most common types of ventilation deflectors today:

- TsAGI;

- Grigorovich;

- in the shape of a star "Shenard";

- ASTATO open;

- spherical "Volper";

- H-shaped.

Plastic ventilation deflectors are rarely used as they are short-lived and fragile. It is allowed to install plastic deflectors for ventilation of basements, basements. Plastic deflectors are widely used only as car accessories.

Some consumers mistakenly call distribution devices for ventilation of stretch ceilings deflectors. Ventilation deflectors are installed only at the ends of the exhaust ducts. Ventilation of exhaust ceilings is provided by diffusers and diffusers through which air enters the room evenly and in the required quantities.

Deflector ASTATO

A model of a rotating ventilation deflector that uses both mechanical and wind draft. With sufficient wind power, the engine is switched off and the ASTATO operates according to the exhaust ventilation deflector principle. An electric motor is started in the calm, which does not in any way affect the aerodynamics in the ventilation system, but provides a sufficient vacuum (no more than 35 Pa).

The electric motor is very economical, it is turned on by a signal from a sensor that measures the pressure at the outlet of the ventilation duct. In principle, the ventilation deflector is wind-driven for most of the year. The ASTATO ventilation deflector device includes a pressure sensor and a time relay, which automatically start and stop the engine. This can be done manually if desired.

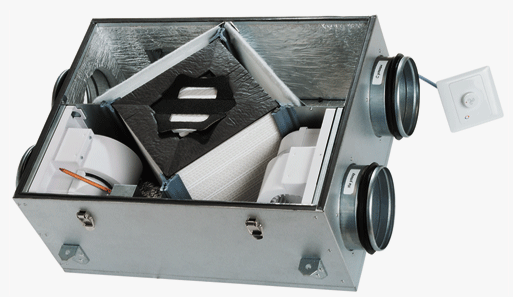

Static deflector with ejection fan

The partially rotating ventilation deflector is a new product that has been very successful for several years. DC deflectors are installed at the outlets of the ventilation ducts, low-pressure fans with reduced noise emission are located just below. The fans are started by a pressure transducer. The glass is made of galvanized steel with thermal insulation. Soundproofed air ducts and drainage are connected to it. The entire structure is covered from below by a suspended ceiling.

Deflector-weather vane

The device belongs to the category of active ventilation deflectors. It is rotated by the force of moving air currents. The housing with covers rotate due to the bearing module. When driving between the canopies, the wind forms a zone of reduced pressure. The advantage of this type of ventilation deflector is the ability to "adjust" to any wind direction and good protection of the chimney from the wind. The disadvantage of a rotating ventilation deflector is the need to lubricate the bearings and monitor their condition. In severe frosts, the weather vane freezes over and performs its function poorly.

Rotary turbine

In calm weather, a turbo deflector for ventilation in the form of a turbine is completely useless. Therefore, rotary turbines are not so widespread, despite their attractive appearance. They are installed only in areas with a stable wind. Another limitation is that such a turbo deflector cannot be used for chimneys of solid fuel stoves, as it can deform.

DIY ventilation deflector

Most often, a Grigorovich deflector is made with their own hands for ventilation. The device is quite simple, and the operation of this type of ventilation deflector is uninterrupted.

To make a Grigorovich ventilation deflector with your own hands, you will need:

- galvanized or sheet stainless steel;

- rivets, nuts, bolts, clamp;

- electric drill;

- scissors for metal;

- scriber;

- ruler;

- pencil;

- compass;

- several sheets of cardboard;

- scissors on paper.

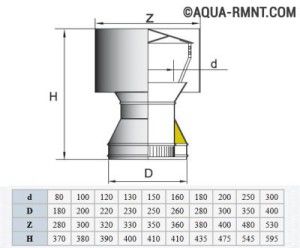

Step 1. Calculation of deflector parameters

At this stage, you need to calculate the dimensions of the ventilation deflector and draw a diagram. All initial calculations are based on the diameter of the ventilation duct.

H = 1.7 x D,

Where H - deflector height,D - chimney diameter.

Z = 1.8 x D,

Where Z - cap width,

d = 1.3 x D,

d - diffuser width.

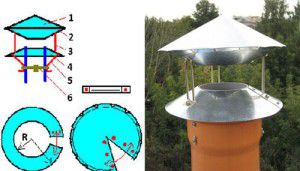

On cardboard we create a diagram of the ventilation deflector elements, do it yourself and cut it out.

If you have no experience in making deflectors, we recommend practicing on a cardboard model.

Step 2. Making a deflector

We draw a scribe around the patterns on a sheet of metal and with the help of scissors we get parts of the future device. We connect the parts together with small bolts, rivets or welding. To install the cap, we cut out the brackets in the form of curved strips. We fix them outside the diffuser, attach the reverse cone to the umbrella. All components are ready, now the entire diffuser is assembled directly on the chimney.

Step 3. Installing the deflector

We install the lower glass on the chimney pipe and fasten it with bolts. We put on the diffuser (upper glass) on top, clamp it with a clamp, attach the cap to the brackets. The work on creating a ventilation deflector with your own hands is being completed by installing a reverse cone, which will help the device to function even with an unwanted wind direction.

Ventilation deflector selection

Any owner wants to choose a deflector for ventilation as efficient as possible.

The best models of exhaust ventilation deflectors are:

- disc-shaped TsAGI;

- DS model;

- ASTATO.

The deflector operation during calculations is determined by two parameters:

- discharge coefficient;

- coefficient of local losses.

The coefficients depend only on the model and not on the dimensions of the ventilation deflector.

For example, for DS, the coefficient of local losses is 1.4.

The vacuum coefficient is influenced by the wind speed.

Calculation of a deflector for ventilation type DS.

| Wind speed in km / h | 0,005 | 0,007 | 0,01 |

| Additional wind vacuum, Pa | 11 | 21,6 | 44,1 |

A method has been developed for selecting a ventilation deflector based on the total wind vacuum.

Although ventilation deflectors have been undeservedly forgotten in recent decades and have been widely replaced by umbrellas, today they are making a comeback. This is a really inexpensive and effective way to improve the performance of natural ventilation in residential and public buildings.

A video about a spark arrester deflector for ventilation and how to choose it:

Hello! A very interesting article, but you do not have any drawings of the deflector, at least indicative. I am just equipping the dacha and I need to finish the chimney zone. I would be grateful for your help.

Hello! Dimensions are given in the article on one of the images. From them it is already possible to calculate the cutting in place.