Ventilation doors are needed to control the flow of incoming or outgoing air. So, doors are widely used in mines, on passenger aircraft, in industrial enterprises. In residential and industrial construction, ventilation grids or openings are analogous to ventilation doors.

Doors with ventilation grill in mines

In shafts, ventilation doors are part of the air exchange bulkhead. It serves to isolate the air stream in artificial earth cavities formed in the course of work (workings). To minimize air leaks, two or more ventilation doors are installed in a row in the shafts, which form a ventilation lock.

Doors are fastened in lintels made of concrete, stone or wood. In order for the flaps to close on their own, the frame is located at an incline of 80 degrees or is equipped with springs, counterweights. If there is a lot of traffic in the mine, the mine ventilation doors open automatically.

The air movement between the workings is regulated by means of windows and dampers on the ventilation shaft doors. Doors can be double-leaf or single-leaf. They are made of metal or wood. The thickness of the board for wooden doors is 40 mm or two layers of 20 mm each. Thickness of sheet steel for metal doors is 3-4 millimeters. The metal is welded onto the frame from a strip or corner.

Aircraft ventilation doors

In passenger aircraft, ventilation doors are used to equalize the pressure in the aircraft and overboard during landing. The problem with the operation of ventilation doors in airplanes is icing, which often occurs when there is a large temperature difference between the inside and outside of the airplane. Sometimes frost appears around the perimeter of the door, which makes it difficult to open it. The door ventilation system helps to avoid icing.

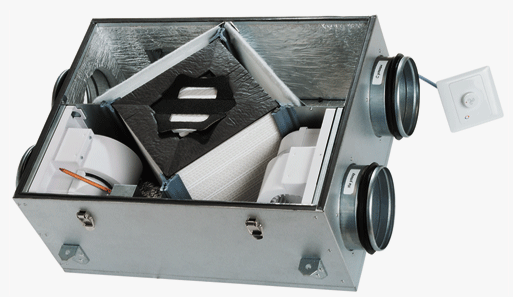

Doors for ventilation chambers

Special design doors are installed in ventilation chambers, ducts and central air conditioners. They are manufactured in accordance with TU and must have a certificate of conformity. Doors for ventilation chambers can be:

- insulated DUs (insulation - thin fiberglass);

- not insulated Ds.

The difference between doors for ventilation chambers is in hermetically sealed closure.

Airtight doors for ventilation chambers are a metal door leaf and a metal frame. Of course, sealed metal doors are not equipped with ventilation grilles. The blade rotates freely on the hinges. If the door is not insulated, the door leaf is single. The insulated door consists of two sheets of metal with insulation between them.

The door frame is welded to the specially provided fittings for the opening. If the reinforcement is not laid in advance, it must be driven into the drilled holes. It can also be welded to the metal edging of the opening.

The door closes with a wing fastening.

Installation restriction: explosion-proof rooms of categories A and B. Pressurized doors should not be confused with fire doors. They are not supplied with a fire safety certificate, for them a fire resistance limit is not determined.

Fireproof doors with ventilation grill

The purpose of fire doors is to prevent fire and smoke from entering or entering the premises. The main characteristic of fire doors is the fire resistance limit. This is the time that the door confronts the fire. It is 15 - 120 minutes and is indicated in the certificate of conformity. Fire-rated doors can be single or double. During their production, technical standards are carefully observed. Fireproof doors with a ventilation grill are made of sheet steel or wood. Wooden doors are equipped with a special seal that retains smoke or fire. During heating, the seal melts and fills all the cracks. Outside, the door is no different from the usual one. The boxes are made of solid wood. A steel or aluminum fire-rated door with a ventilation grill is a double rebate with a fire-resistant sealing layer. Mineral wool slabs are usually used as an insulating layer.

Ventilated fire doors are fitted with an air intake grille at the bottom of the door.

There are metal doors with ventilation grilles and glazing. The glass is heat-resistant, not cracking from high temperatures.

Along the perimeter, metal fire doors with a ventilation grill are glued with a sealing tape made of fire-resistant thermo-expanding material, which prevents the spread of smoke. Video on how the fire resistance of a door is tested:

Special locks for fire doors are used, they ensure a tight fit of the door and frame and are equipped with the Anti-Panic system. This means, on the one hand, the door is opened by simply pressing the handle so that people can freely leave the burning room, on the other - only with a key.

Interior door with ventilation grill

You can make a ventilation door out of an ordinary door with your own hands and it's not difficult at all.

Bathroom doors are in dire need of ventilation holes. There is high humidity in the room and there are no windows, and a tight fit to the door frame excludes air movement. Moisture settles on the walls, creating an excellent environment for germs and mold to grow. In most cases, a ventilated door improves air exchange and reduces room humidity.

Ventilation holes are made at the bottom of the door. Their total area should be 200 sq. cm for the door to the bathroom or kitchen and 80 sq. cm for interior doors.

Work progress:

- Marking is made at the bottom of the door leaf;

- A drill with a special nozzle makes holes corresponding to the diameter of the ventilation rings;

- Rings are installed.

The rings are sold in a variety of colors and are very easy to install and give the vents a clean finish. There are rings with mesh and even noise protection. The special material allows air to enter, but does not allow noise to pass through.

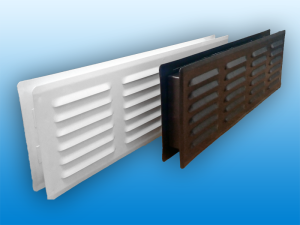

You can also equip the door with ventilation using a grill. The lattice completely excludes the possibility of peeping, since the horizontal slats are fixed at an angle. Ventilation grilles for the door are made of various shapes, with adjustable shutters, with noise protection and simple, without "bells and whistles". They are made from metal, plastic and even wood.

The most popular are plastic grilles of various colors. They are very neat and do not spoil the look of the door at all.

The most difficult step in installing a ventilation grill on a door is drilling a hole. It must be made rectangular 1 mm more than the inner surface of the grille. Further, both halves of the grille are treated with glue or sealant and applied to the hole in the door. The gratings are held by glue or self-tapping screws. Some models are equipped with a bushing to which the two grille pieces are attached.

And the easiest way to make a ventilated door yourself is to cut it from the bottom. It will be impossible to notice the undercut, and to make it absolutely neat, the butt piping is used. So even under a tightly closed door there will be a gap for air movement.