An autonomous water supply system in a personal plot has many advantageous features, however, for its functionality it is important not only to drill a source, but also to choose the right one and install a casing pipe. It is necessary to reliably strengthen the walls of the mine, which increases the life of the well, and also improves the quality of the extracted water resource.

What are casing pipes

Before purchasing casing pipes and proceeding with their installation, you need to figure out what functions are assigned to them.

The casing pipe is equipped with a reinforced casing. Its main task is to strengthen the internal structure of a well or well. As a rule, to strengthen artesian wells, it is required to install several functional elements that form a single casing. At the construction stage, it is important to create tightness of all joints, otherwise soil and waste water will penetrate from the outside into the well water.

The wall thickness of the casing string depends on the materials used, such as the hydraulic structure in which it is installed.

Casing pipes are designed to perform the following functions:

- Prevents possible contamination from entering the column, which could render the water unusable and damage pumping equipment.

- Ensure the integrity of the entire structure throughout the entire service life. Casing pipes are made from materials of increased strength. They are able to withstand high pressure of soil layers at depth, are inert to deformations, soil shifts and damage.

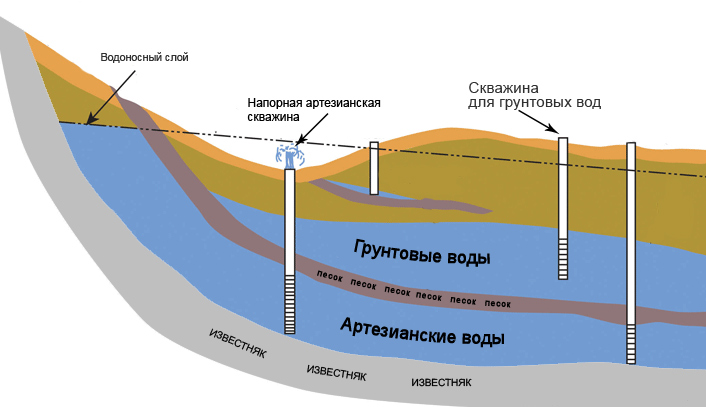

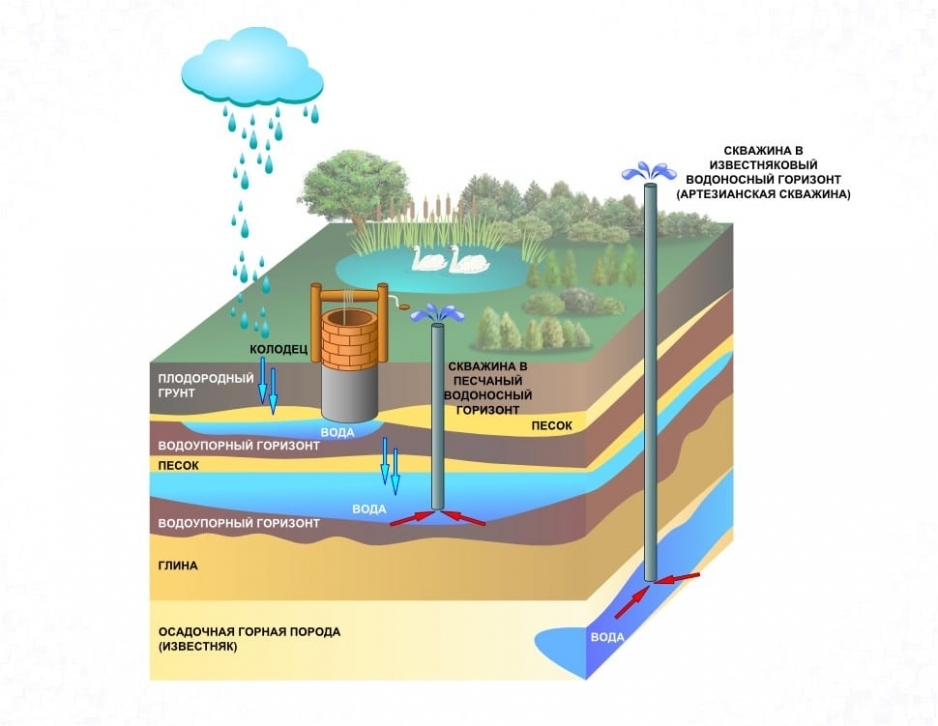

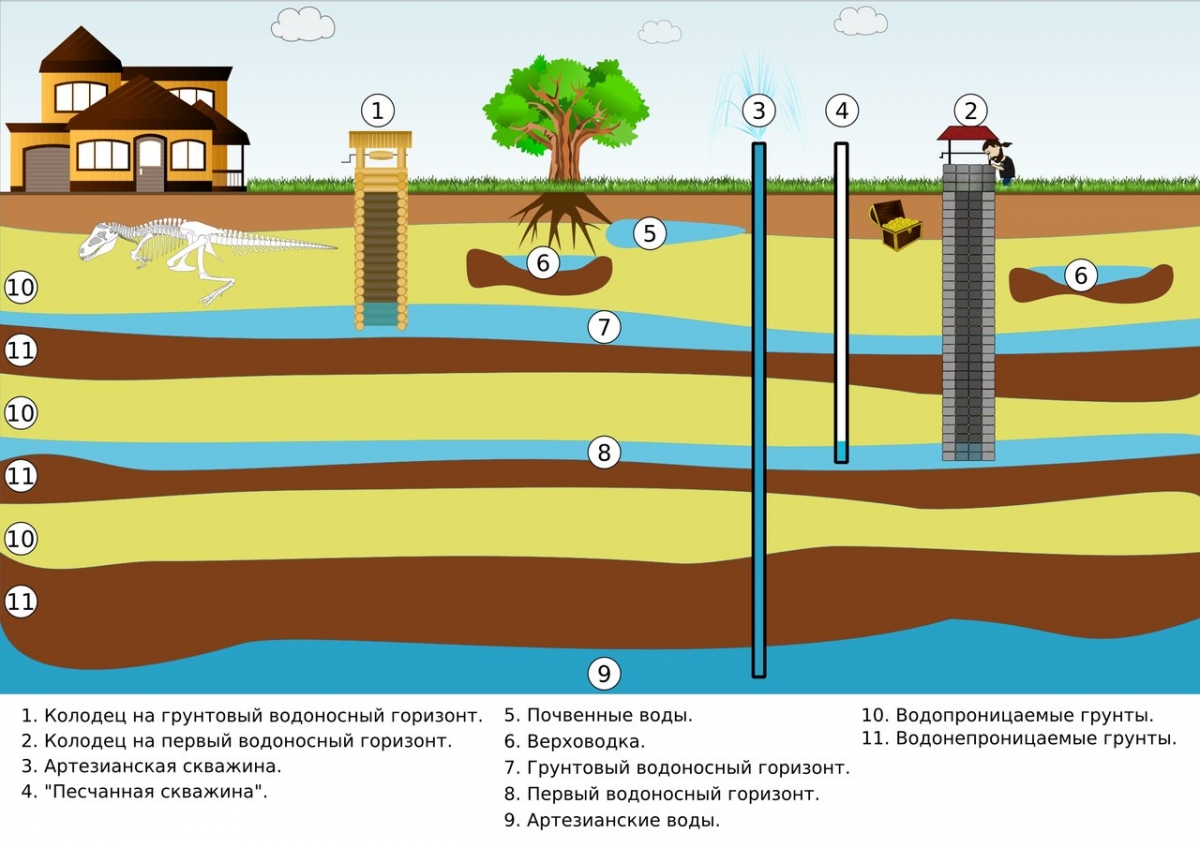

- They protect the hydraulic structure from increased pressure, especially at great depths (the aquifer in artesian springs can be at a depth of more than 50 meters).

- Retain usable water within the casing.

In order to reliably seal all connections, preference should be given to the threaded connection method.

Selection of pipes for well casing

The performance of the system will depend on how well the casing diameter has been selected. To calculate the parameter, you need to take into account the depth and productivity of the source, as well as the required daily volume of water, which will be enough for cooking, watering the garden and other household needs.

Don't rely solely on performance. The durability and reliability of the entire structure and system depends not only on the length and diameter of the casing, but also on the material of its manufacture.

For installation in water wells, pipes are made from the following materials:

- metal and alloys;

- asbestos cement;

- plastic and polymers;

- wood.

It is difficult to answer unequivocally which material will be most suitable in a particular case. It depends on climatic and operating conditions, diameter and productivity of the water intake source, technical characteristics of pumping equipment.

Metal casing

Metal products designed to create a casing in a well can be:

- galvanized;

- cast iron;

- made of stainless steel;

- steel;

- enameled.

Metal products are considered the most popular and reliable for the arrangement of a well or well. This is due to the full compliance with the technical requirements that are presented to the materials by the regulatory legal acts of GOST, SanPiN, etc. Most often they are used for arranging artesian wells when work is carried out in sandy and / or limestone soil.

The main advantages of a building material include:

- high strength and resistance to mechanical stress and deformation;

- continuous and uninterrupted supply of high-quality water throughout the entire operational period;

- for the tightness of the connection of structural parts, a threaded connection is used (the most reliable of all existing ones);

- the ability to clean the source when silting the bottom using a special drilling tool;

- the service life of a metal pipe with a wall thickness of 6 mm reaches half a century.

There are also many disadvantages:

- lack of resistance to corrosion - after a while, a rusty sediment appears in the water;

- high cost of consumables;

- difficulties in self-installation due to the impressive weight of thick-walled metal structures.

In addition to steel pipes, you can still give preference to stainless, galvanized and enameled models. Pipes with an enamelled protective surface are also susceptible to rust, which occurs when the layer is damaged or deformed.

Galvanized steel structures are not afraid of corrosion, but they pollute the water intake point with zinc oxide. They have a long service life.

Asbestos cement material

Due to its high resistance to aggressive environmental factors (salts and other chemical elements) and mechanical stress, as well as an acceptable cost, asbestos cement products are in great demand in the construction and arrangement of hydraulic structures.

The main advantages of the material include:

- long service life (with proper use and maintenance) - up to 65-70 years;

- practicality and complete safety of operation;

- affordable price;

- absolute corrosion resistance.

Despite the rather extensive list of advantages, there is a rather large list of significant disadvantages:

- Difficulties in carrying out installation work. You cannot do without the help of expensive lifting equipment.

- Also, difficulties arise in the service process. This is due to the high porosity of the surface, where dirt accumulates. Thorough cleaning of the casing will require a complete drain of the source.

- There is no threaded connection. Fixation of structures is carried out joint to joint, which cannot guarantee proper sealing of the seams.

- A characteristic feature of asbestos cement is increased fragility.

Building materials made of asbestos cement are not used for arranging artesian springs in limestone soil.

Plastic building materials

Plastic pipes for the arrangement of water intake sources are in increasing demand every year, due to the large number of advantages in comparison with the two previous analogues. They are made from polyethylene, polypropylene and PVC. Material advantages:

- long service life;

- affordable cost of consumables;

- high resistance to the destructive effects of chemical elements, including salts;

- low weight of structures;

- resistance to rust formation;

- a threaded connection provides a high degree of tightness of the components of the structure;

- affordable and simple installation that can be done even by a novice master.

Even with prolonged use of a plastic pipeline, the chemical composition of water does not change, pathogenic, pathogenic microorganisms do not develop in it.

Plastic is most often used when arranging springs in sandy soil with an aquifer depth of no more than 55 meters. Also, similar building structures are used for the construction of filter columns.

Well casing installation rules

Carrying out work on drilling and installing casing pipes is a laborious process, the durability of the source, as well as the quality of the produced water, will depend on the quality of the work done.

If the depth of the aquifer is no more than 1-15 meters, you can design, drill and equip the source yourself. During the work, you must strictly follow the rules of personal safety, carefully approach the choice of building materials and tightness, accuracy of assembly.

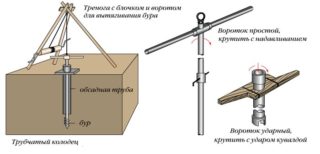

You need to do the work with a partner, one person will not cope with the task at hand or will simply overstrain. Before starting work, you need to make sure that all work equipment and tools are prepared. Required:

- spanners and wrenches of various sizes, as well as sledgehammers and hammers;

- a drill, in the form of a bailer, equipped with a thread for connecting pipes;

- tripod, which greatly simplifies the process of performing work;

- a gate that allows the pipe to rotate in the ground for more accurate casing installation.

If all the inventory is prepared, you should familiarize yourself with the technology of drilling and installing the casing string with your own hands:

- With the help of a drill, which is securely connected to the pipe, a recess is made in the ground. With a gradual immersion in the soil layers, the tool must be regularly removed in order to clean up the adhering rock. As soon as the immersion depth reaches 2 meters, the brought casing is inserted.

- As soon as the aquifer has been reached, the casing is fixed, a polymer pipe is passed through the formed shaft, connected to a submersible (deep) water pump.

The technology is not difficult, but you need to be patient. Sometimes the work takes several years, because it is impossible to reliably say at the design stage at what depth the aquifer is located.

When choosing materials for the construction of the casing string, one should be guided by the classic combination of quality and cost, which will help determine the durability of a hydrological structure. Sources of great depth are best designed with metal structures equipped with external and internal threads. If the depth of the aquifer does not exceed 55 meters, it is recommended to give preference to plastic products, also equipped with threads for reliable sealing.