In order to continuously provide a dacha or a cottage with water, you need a high-quality source of water supply, a pipeline and an automatic water supply station. Compact, easy-to-operate stations are widely used in suburban engineering networks. Homeowners who are not ready to pay big money for a ready-made factory installation will learn from our material: how and from what to assemble an automatic water supply station with their own hands.

The design and principle of operation of the water supply station

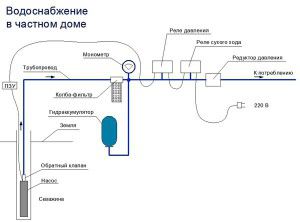

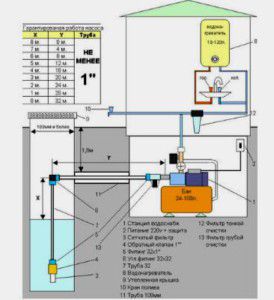

The task of the automatic water supply pumping station is to supply water and maintain the required pressure in the pipes. To ensure all the master's needs, the system must contain:

- hydroaccumulator - accumulates water at a given pressure, equalizes pressure drops;

- self-priming pump;

- check valve - prevents the outflow of water from the pipes during pump downtime;

- dry running sensor - cuts off the power supply to the pump when there is no water in the pipes;

- pressure switch and gauge... The pressure switch supplies and stops the power supply to the pump. The pressure gauge shows the pressure in the system, is indispensable when setting up or repairing an automatic water supply station;

- pressure reducer - stabilizes the maximum pressure in the consumer network;

- control module or ROM - a start-up device, as a rule, is included in the pump package.

The principle of operation of an automatic water supply pumping station is simple: water is sucked in by a pump and supplied to a hydraulic accumulator. The tank holds a certain amount of water, the pressure of which is set using a relay. When the pump is at a standstill, water for use is supplied from the accumulator tank. As the water level decreases, the pressure drops, at the set point, the pump starts. According to this cycle, an automatic water supply station with a hydraulic accumulator operates.

The capabilities of an automatic water supply station depend on the capacity of the accumulator tank. With a small volume, the pump will start after each dishwashing, which will negatively affect the resource of its operation. It is estimated that one tenant of a private house spends about 250 liters of water per day.

Residents of the house can use water during a power outage within the volume of the tank. The pressure in the pipes will be kept in the range from 1.5 to 3 atmospheres, sufficient for any domestic needs.

Selection and preparation of the installation site for the water supply station

The main disadvantage of automatic water supply pumping stations is their noisy operation. And although many manufacturers are working to eliminate it, we recommend installing and installing an automatic water supply system away from residential premises and closer to the source of the water intake.

For smooth operation, you need a rigid base and good fasteners, which are easiest to provide on a concrete site. A possible alternative to the base for an automatic do-it-yourself water station is a wooden base. For the construction you will need:

- boards 50 mm thick;

- bar 100x150 mm;

- nails;

- clay, sand.

Work order:

- Cut off 2 pieces of timber 600 mm longer than the width of the station, treat them with an antiseptic.

- We dig ditches for the bars, lay them, check the horizontal level.

- We tamp the earth around the bars with sand and clay.The bars should not protrude more than 5 cm above the ground.

- On the bars we stuff a shield made of boards pre-treated with an antiseptic.

- Before installing and attaching an automatic water supply station with a hydraulic accumulator, check the horizontal level again with a level!

Install the station using rubber pads 1 cm thick. Do not use pads that are too thick to reduce rigidity and cause vibration.

Station installation and connection

The procedure and diagram for connecting a pumping station for automatic water supply are the same for any source of water intake:

- We start by assembling the ejector. It is a cast iron construction with multiple sockets for fastening.

- We attach a coarse filter to the lower outlet.

- We attach a squeegee assembled from 2 parts to the upper plastic socket. We measure the required length.

- A metal coupling is attached to the squeegee socket as an adapter for a polypropylene pipe. The joints are carefully sealed.

- Water pipes are laid in ditches prepared in advance. For turns, we leave a small margin in length.

- For casing, an elbow with a suitable bend radius is usually selected.

- The ejector is attached to the pipe with a coupling joint.

- The second end of the pipe is passed through the elbow at a right angle, the structure is foamed and only after that it is lowered. Now we attach the pipe to the external line with an angle adapter.

- The assembled ejector is introduced into the water intake source to the depth of the casing, which is planned in advance.

- We wrap the fastening of the ejector bell and the casing with metallized tape.

An important point in observing the connection diagram of the automatic water supply pumping station is the quality of the water. Well or well water always contains some inclusions that are dangerous for the mechanisms. Without filtration, grains of sand, soil particles will gradually accumulate in the accumulator, leading to breakdown and repair of the most expensive element of an automatic water supply station - a pump. Therefore, a filter is installed in front of the pump. Vibration pumps are more vulnerable to mechanical impurities.

It must be remembered that a dirty filter creates additional resistance to the flow of water, reduces the head and increases the load on the engine.

The most common mistakes during the installation and installation of an automatic water supply system:

- During the laying of the line, the pipes are cut off without reserve for the thickness of the foundation and turns.

- Threaded nuts are loose. If you tighten the connections by hand, leaks will be found during operation.

- The pressure in the accumulator should not go below 1.2 atmospheres. It should be lifted with a car pump or compressor.

Setting up a water station

The purpose of setting up an automatic water supply station with your own hands is to obtain the optimal pressure:

- We set the lower pressure threshold in the accumulator at around 1.3 atmospheres. This is done by a compressor or a car pump when there is no pressure in the system.

- We set the threshold of the dry-running relay to the maximum mark.

- The pressure reducer is adjusted according to its instructions. To set the highest pressure mark on the reducer there is a knob or a screw. The reducer threshold must be 0.5 atmospheres higher than the relay threshold.

A factory pumping station is much easier to set up. Pour about 2 liters of water through the provided hole into the body and carefully monitor the pressure. The pump should turn on at 1.6 -1.8 atmospheres, and turn off at 2.6 - 3 atmospheres.

Remove the cover from the relay and turn the screw "ДР" towards "+" - to increase or towards "-" - to lower the shutdown pressure. Switch-on pressure is regulated by screw "P".

The installation and installation of the factory automatic water supply system can be carried out by masters from the service center. They, if necessary, will repair the automatic water supply station.

A video on how to independently provide a house with water: